Chapter: Mechanical : Design of Machine Elements : Design of Temporary and Permanent Joints

Design of Temporary and Permanent Joints

DESIGN

OF TEMPORARY AND PERMANENT JOINTS

Welded

Joints

A

welded joint is a permanent joint which is obtained by the fusion of the edges

of the two parts to be joined together, with or without the application of

pressure and a filler material. The heat required for the fusion of the

material may be obtained by burning of gas (in case of gas welding) or by an

electric arc (in case of electric arc welding). The latter method is

extensively used because of greater speed of welding.

Welding

is extensively used in fabrication as an alternative method for casting or

forging and as a replacement for bolted and riveted joints. It is also used as

a repair medium e.g. to reunite metal at a crack, to build up a small part that

has broken off such as gear tooth or to repair a worn surface such as a bearing

surface.

Advantages and Disadvantages of Welded Joints over Riveted Joints

Following are the advantages and

disadvantages of welded joints over riveted joints.

Advantages

The

welded structures are usually lighter than riveted structures. This is due to

the reason, that in welding, gussets or other connecting components are not

used.

The

welded joints provide maximum efficiency (may be 100%) which is not possible in

case of riveted joints.

Alterations

and additions can be easily made in the existing structures.

As

the welded structure is smooth in appearance, therefore it looks pleasing.

In

welded connections, the tension members are not weakened as in the case of

riveted joints.

A

welded joint has a great strength. Often a welded joint has the strength of the

parent metal itself.

Sometimes,

the members are of such a shape (i.e. circular steel pipes) that they afford

difficulty for riveting. But they can be easily welded.

The

welding provides very rigid joints. This is in line with the modern trend of

providing rigid frames.

Disadvantages

Since

there is an uneven heating and cooling during fabrication, therefore the

members may get distorted or additional stresses may develop.

It

requires a highly skilled labour and supervision.

Since

no provision is kept for expansion and contraction in the frame, therefore

there is a possibility of cracks developing in it.

The

inspection of welding work is more difficult than riveting work.

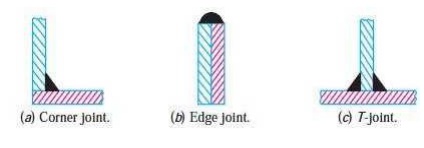

Types

of Welded Joints

Following two types of welded joints

are important from the subject point of view:

Lap

joint or fillet joint, and

Butt

joint.

Lap

Joint

The lap joint or the fillet joint is

obtained by overlapping the plates and then welding the edges of the plates.

The cross-section of the fillet is approximately triangular. The fillet joints

may be

Single

transverse fillet,

Double

transverse fillet, and

Parallel

fillet joints.

The fillet joints are shown in Fig.

A single transverse fillet joint has the disadvantage that the edge of the

plate which is not welded can buckle or warp out of shape.

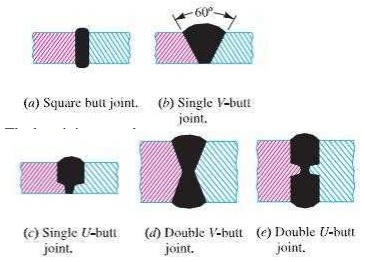

Butt

Joint

The butt joint is obtained by

placing the plates edge to edge as shown in Fig. 10.3. In butt welds, the plate

edges do not require bevelling if the thickness of plate is less than 5 mm. On

the other hand, if the plate thickness is 5 mm to 12.5 mm, the edges should be

bevelled to V or U-groove on both sides.

The butt joints may be

Square

butt joint,

Single

V-butt joint

Single

U-butt joint,

Double

V-butt joint, and

Double

U-butt joint.

Riveted

Joints

A

rivet is a short cylindrical bar with a head integral to it. The cylindrical

portion of the rivet is called shank or body and lower portion of shank is known as tail, as shown in Fig. The rivets are

used to make permanent fastening between the plates such as in structural work,

ship building, bridges, tanks and boiler shells. The riveted joints are widely

used for joining light metals. The fastenings (i.e. joints) may be classified

into the following two groups:

Permanent

fastenings, and

Temporary

or detachable fastenings.

Types

of Riveted Joints

Following are the two types of

riveted joints, depending upon the way in which the plates are connected.

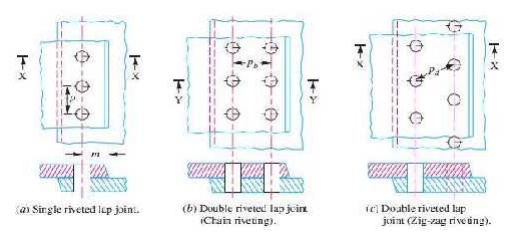

Lap

joint, and

Butt

joint.

Lap

Joint

A

lap joint is that in which one plate overlaps the other and the two plates are

then riveted together.

Butt

Joint

A

butt joint is that in which the main plates are kept in alignment butting (i.e.

touching) each other and a cover plate (i.e. strap) is placed either on one

side or on both sides of the main plates. The cover plate is then riveted

together with the main plates. Butt joints are of the following two types:

Single

strap butt joint, and

Double

strap butt joint.

In

a single strap butt joint, the edges of the main plates butt against each other and

only one cover plate is placed on one side of the main plates and then riveted

together.

In

a double strap butt joint, the edges of the main plates butt against each other and two

cover plates are placed on both sides of the main plates and then riveted

together.

In

addition to the above, following are the types of riveted joints depending upon

the number of rows of the rivets.

Single

riveted joint, and

Double

riveted joint.

A single riveted joint is that in which

there is a single row of rivets in a lap joint as shown in Fig. (a) and there

is a single row of rivets on each side in a butt joint as shown in Fig.

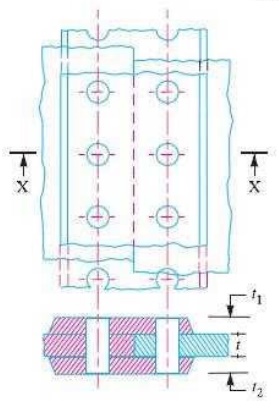

A

double riveted joint

is that in which there are two rows of rivets in a lap joint as shown in Fig.

(b) and (c) and there are two rows of rivets on each side in a butt joint as

shown in Fig.

Important

Terms Used in Riveted Joints

The following terms in connection

with the riveted joints are important from the subject point of view :

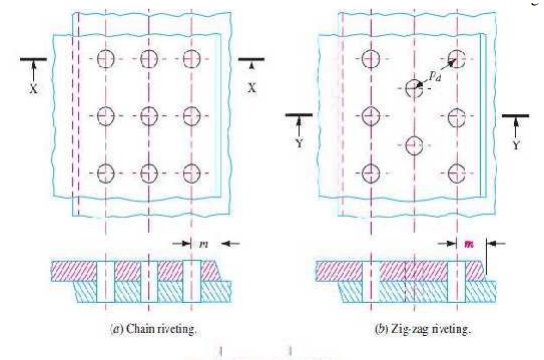

1. Pitch. It is the distance from the centre of one rivet to the

centre of the next rivet measured parallel to the seam as shown in Fig. 9.6. It

is usually denoted by p.

Back pitch. It

is the perpendicular distance between the centre lines of the successive rows

as shown in

Fig. It is usually denoted by pb.

Diagonal pitch. It

is the distance between the centres of the rivets in adjacent rows of zig-zag riveted joint as shown in Fig. 9.6.

It is usually denoted by pd.

Margin or marginal pitch. It is the distance between the

centre of rivet hole to the nearest edge of the plate as shown in Fig. 9.6. It is usually denoted by

m.

Efficiency

of a Riveted Joint

The

efficiency of a riveted joint is defined as the ratio of the strength of

riveted joint to the strength of the un-riveted or solid plate.

We have already discussed that

Strength of the riveted joint =

Least of Pt, Ps and Pc

Strength of the un-riveted or solid

plate per pitch length,

P = p × t × σt

Efficiency of the riveted joint,

η = (Least of Pt , Ps and Pc) / (p ×

t × σt)

where p = Pitch of the rivets,

t = Thickness of the plate, and

σt = Permissible tensile stress of

the plate material.

Related Topics