Chapter: Civil : Design Of Reinforced Concrete And Brick Masonry Structures- Retaining Walls: Design Of Water Tank

Design Of Water Tank

DESIGN OF WATER TANK

Classication:

1.

C Cylindrical

2.

Rectangular

Further,

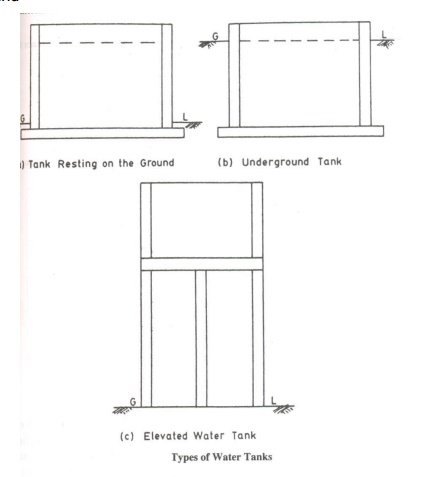

water tanks are classified based on their positions as,

1. Resting

on ground

a. Flexible

or free base

b. Hinged

c. Fixed

2.

Elevated or overhead

3.

Underground

Components

of water tank:

1. Side

Walls [Rectangular or cylindrical]

2. Base

slab

3. Cover

slab or dome

4. Staging

[Overhead] à

Columns, Beams, Bracings

Types

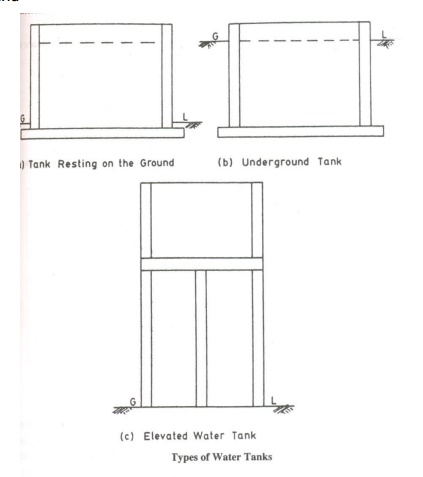

of Joints:

i)

Flexible base

ii)

Hinged base

iii)

Fixed base

Water pressure distribution:

1. On side

walls, it acts

linearly varying fr

2. On base

slab, uniform pressure

acts with i

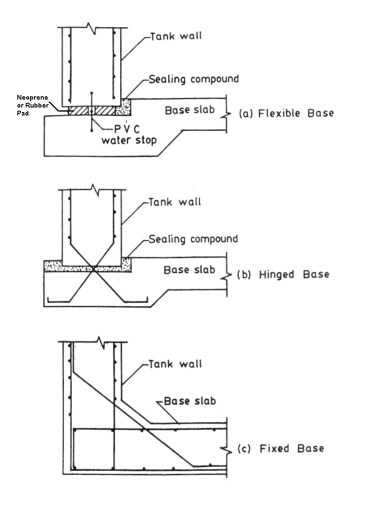

Permissible stresses:

The method of design adopted

for design of water tank is working stress method. The permissible stress

values in concrete and steel are given in Tables 21 and 22 of IS456-2000, as

follows:

For M20 à ?cbc

= 7 N/mm2, t =?5 N/mm2

2

For Fe250 steel,-140N/mm?st = 130

2

For Fe415

steel,-240N/mm?st = 230

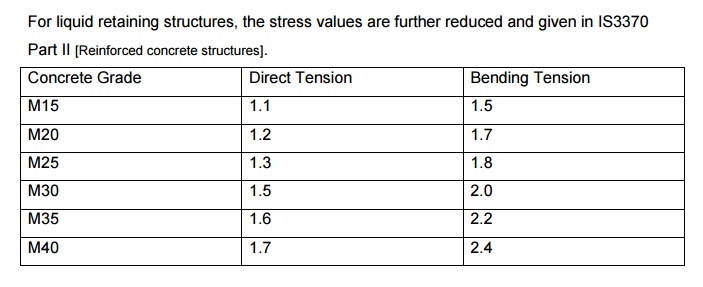

For

liquid retaining structures, the stress values are further reduced and given in

IS3370

Part

II [Reinforced concrete structures].

Concrete Grade, Direct Tension , Bending Tension

M15 1.1 1.5

M20 1.2 1.7

M25 1.3 1.8

M30 1.5 2.0

M35 1.6 2.2

M40 1.7 2.4

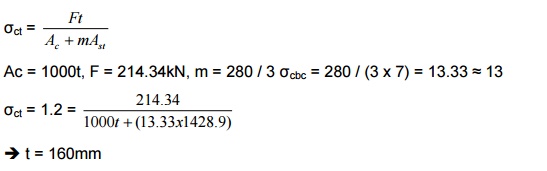

As per clause B -2.1.1, the

tensile stress is given by,

?= Ft / Ac

+ +mAst

where, m à modular

ratiocbc= Es=/E c 280

/ 3 ?

?cbc is the

permissible compressive stress.

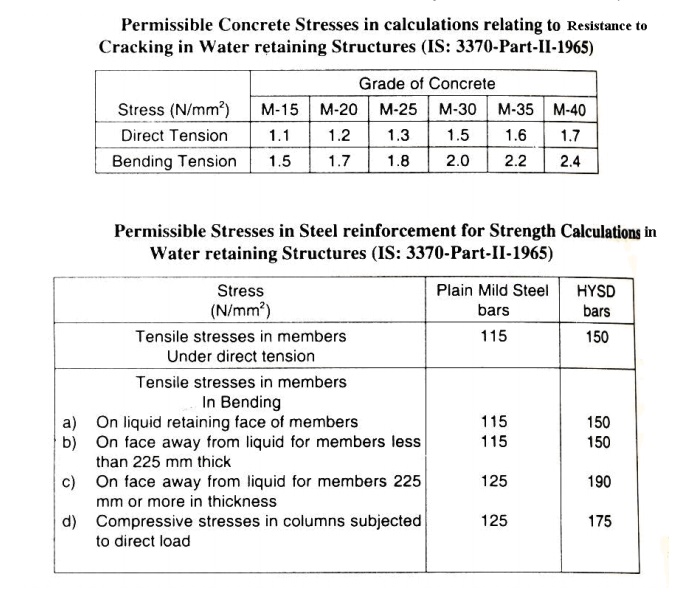

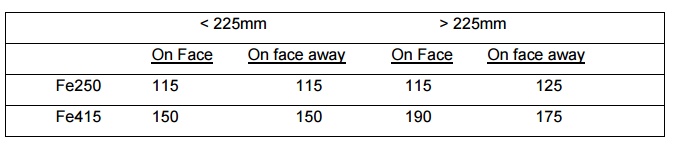

Permissible stress in steel is given in IS3370 Part II as, Tensile stress: Fe250 à 115 N/mm2, Fe415 à 150 N/mm2

Bending stress:

Reinforcement

requirements: [As per IS3370]

1. Minimum

Ast is 0.3% for 100mm section and 0.2% for 450mm section.

2. If

thickness exceeds 200mm, the reinforcement is provided in double layers. A

minimum cover of 25mm is provided along the liquid retained face and the cover

is increased by 12mm (37mm) if the wall is subjected to aggressive soil or

liquid.

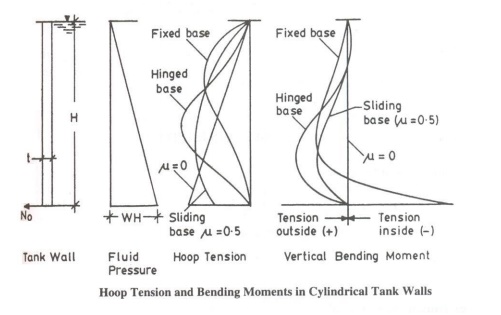

HOOP TENSION AND BENDING

MOMENTS IN CYLINDRICAL TANK WALLS

CYLINDRICAL TANK WITH FLEXIBLE BASE:

The wall is designed for

hoop stress, for which circumferential horizontal steel is provided. Minimum

reinforcement is provided along the vertical direction

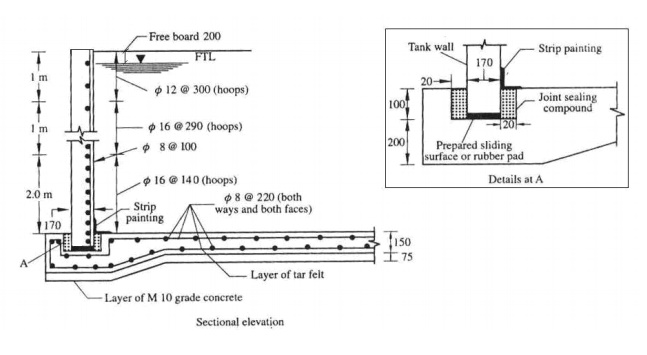

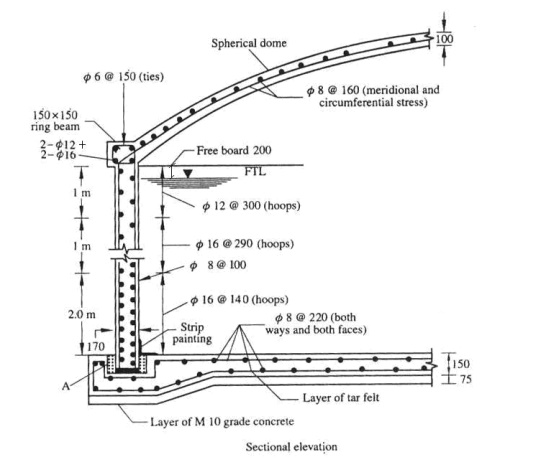

1) Design

a circular water tank with flexible base for a capacity of 4 lakh litres with

the tank having a depth of 4m, including a free base of 200mm. Use M20 concrete

and Fe415 steel. Area of water tank = Volume / Height

= 400 / 4 = 100m2

Provide a diameter of 11.5m

The height of water to be retained = 3.8m

The wall is subjected to hoop tension acting along the

circumferential direction. The hoop tension per metre height is given by,

Hoop

tension = g.h.D / 2 = (9.81 x 3.8 x 11.5)/2 = 214.34 kN

Permissible stress in tension as per IS3370 for Fe415

steel is 150 N/mm2.

Ast required = 214.34 x 103 / 150 =

1428.9 mm2

Spacing = 1000.ast / Ast, à 16mm @ 140mm c/c

Thickness of tank is adopted based on the tensile stress

concrete can take.

Minimum thickness as per

empirical formula is, tmin = (30h + 50)mm where h à m

= 30 x 3.8 + 50 = 164mm

Provide a thickness of 170mm.

Minimum reinforcement is provided as vertical steel.

Minimum Ast is 0.3% for 100mm section and 0.2% for 450mm section.

Therefore, for 170mm thickness, Ast

required is 0.28% of c/s

Ast = (0.28/100) x 1000 x 170 = 476mm2

Provide 8mm @ 100mm c/c

Curtailment of reinforcement:

At 2m height,

Hoop tension = g.h.D / 2 = (9.81 x 1.8 x 11.5) / 2 = 101.5335 kN

Ast = 101.535 x 103 / 150 = 676.89 mm2

Provide 10mm @ 110mm c/c (or) 16mm @ 290mm c/c

Design of base slab:

Since the base slab rests

directly on the ground, a nominal thickness of 150mm is provided and a minimum

reinforcement of 0.3% of c/s is provided along both ways and along both the

faces.

0.3% of c/s à 0.3/100 x 150 x 1000 = 450 mm2,

Required 8mm @110 mm c/c Provide 8mm @220 mm c/c on both faces.

Below the base slab, a layer of lean concrete mix M20 is

provided for 75mm thickness with a layer of tar felt.

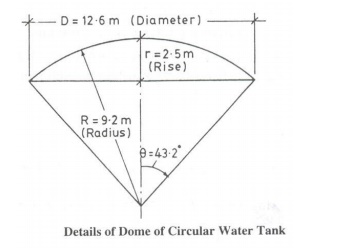

Design of dome: -

Roof covering for cylindrical water tanks

[A dome acts as a roof covering for cylindrical water

tanks. The dome slab is cast between the ring beams provided at the top edge of

the side walls of the water tank. The dome is designed for meridonial thrust

and hoop force].

2) In the above problem,

design a spherical dome having a central rise of one fifth the diameter.

Height = 1/5 x 11.5 = 2.3m

Radius of curvature of the

dome [R] R2 = (R -2.3)2 + 5.752

à R =

8.33m

Cos? =

6.04 / 8.33

= 0.724

The dome is subjected to

meridonial thrust and hoop force, for which the permissible stress should be

within permissible compressive strength of concrete.

?c = 5 N/mm2

Assume thickness of dome as 100mm

Meridonial thrust, T = WR / 1+ +Cosq

w? is the

loading of

and any live load acting on it.

Self weight of slab

= 0.1 x 25 = 2.5 kN/m2 = 2kN/m2

W = 4.5 kN/m2

T = 4.5x8.3 / 1 +0.74 = =

21.46kN

Meridonial thrust = T / (c/s area) = 21.46 x 103

/ (100 x 1000) = 0.21 N/mm2 < 5 N/mm2 The hoop stress

developed in dome slab is given by,

The provided 100mm section

is sufficient. Minimum reinforcement of 0.3% of c/s is provided both ways.

0.3% of c/s = 0.3/100 x 1000 x 100 = 300mm2 à 8mm

@ 160mm c/c

Design of ring beam:

The horizontal component of

meridonial thrust acts on the ring beam. The horizontal thrust, Ast

= HL Comp / s ? where, HL Comp = T.Cos? x D/2 3

x=0 .7421x5.7546=91 .3kNx 10 Ast = 91.3 x 103 / 150 = 608 mm2

Provide (2#

16mm?à(626mm+2#) 12mm?)

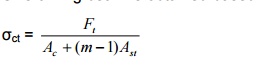

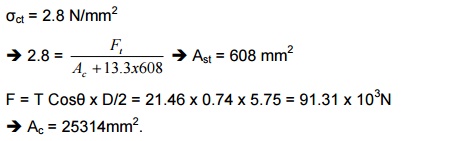

Size of ring beam is obtained based on tensile stress

relation,

Here ring beam is not

subjected to water load. So, permissible tensile stress for M20 concrete is 2.8

N/mm2 (Annex B-3.11) of IS456-2000.

?ct = 2.8 N/mm2

F = T Cos?

x D/2 =

21.46N x 0.74

x 5.75 =

91.3

è Ac

= 25314mm2.

Provide 150 x 150 mm size of ring beam with (2# 16mm? +

2# stress is developed, the steel will take the tensile stress.

DESIGN OF CYLINDRICAL WATER TANK: [With fixed base]

For cylindrical tanks fixed at the base, bending moment

and hoop tension are developed,

whose values are based on non-dimensional parameter, H 2 /

Dt .

The vertical reinforcement is provided for the bending moment developed

and the transverse reinforcement is provided for hoop tension developed.

The coefficients of the non-dimensional parameter H 2/Dt are given in Tables 9 (HT) and 10 (BM).

Maximum hoop tension =

Coefficient x W.H.D/2 Bending moment = Coefficient x w.H3

Where, R à

Radius of tank, D à

Diameter of tank

3)In the above problem, design a water tank for fixed

base condition. Permissible stresses

Min. depth required = 88.23mm

0.3% of c/s (vertical steel)

= 0.28/100 x 1000 x 170 = 476 mm2 Provide 8mm @ 100mm c/c

The maximum of Ast for BM at

Ast {maximum} is provided as vertical reinforcement

[555mm2]. Provide 8mm @ 90mm c/c

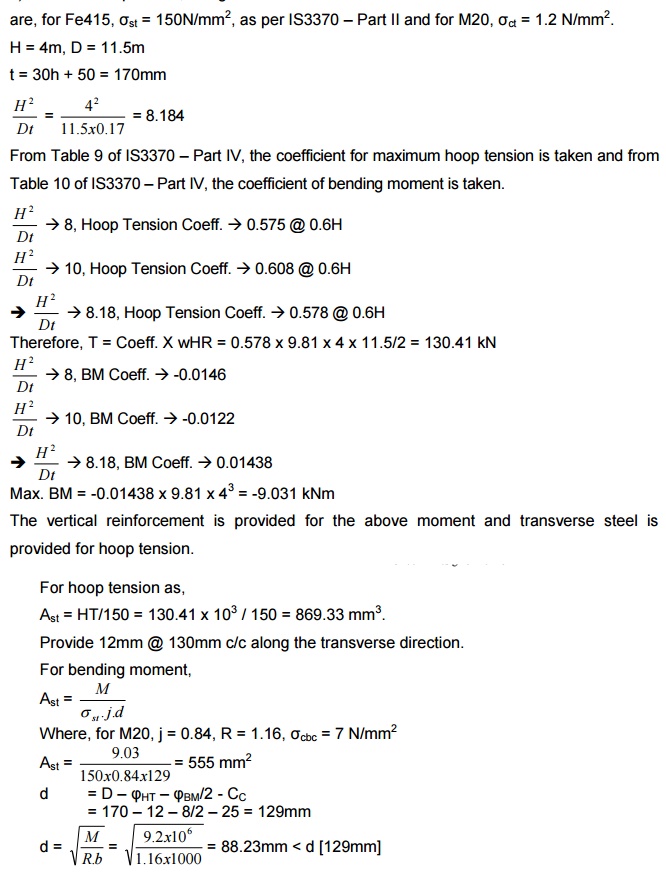

Provide 10mm @ 130mm c/c as

vertical reinforcement. If the reinforcement is provided as double layers on

both the faces, the spacing is doubled.

Provide 10mm @ 260mm c/c as

vertical reinforcement along the two faces with transverse hook reinforcement

at 12mm @ 260mm c/c along both the faces.

Design of base slab:

Provide a nominal thickness

of 150mm for base slab with 0.3% distribution steel [8mm @ 200mm c/c, along

both faces, both ways].

Also

provide a haunch of size 160mm at the junction of the wall and the base slab.

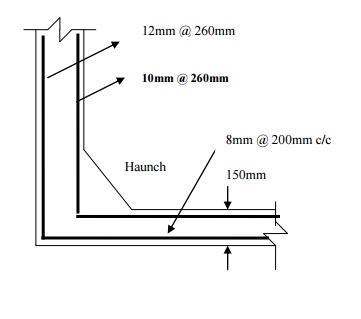

When L / B < 2,

cantilever moment generates at the base and maximum bending action takes place

along the continuous edges of the side walls in both short and long direction.

When L / B > 2, only cantilever action takes place in long wall. Whereas, a

short wall is designed for horizontal bending and cantilever action.

[Cylindrical à

Hoop Tension à

Transverse reinforcement ]

When L/B < 2,

i) Cantilever moment at base = w.H.h2 / 6

where, h = 1m or H/4, whichever greater

ii) For horizontal bending of the walls, the maximum

moment is found from,

a)

Fixed end moments,

PL2/12 and PB2/12

b)

Positive moment at midspan,

Mf

= PL2/8 & Mf = PB2/8

Where, Mf is the

final moment at the supports (junction between long wall and short wall). The

maximum value is taken for design. Here,

P à water pressure given as p = w(H -h)

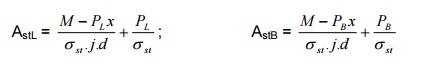

For the maximum moment, the area of steel along the

longer direction and shorter direction are found from the relation,

Where, PL & PB are tension in

long and short walls p -Pressure exerted by water

Tension

in the walls is given by, PL = p x B/2 & PB = p

1. Design a rectangular tank

of size 4m x 6m with height 3m. The tank rests on firm ground. Use M20 concrete

and Fe415 steel. Take design constants j = 0.853 & R = 1.32.

Pressure exerted by water, p = w (H -h)

Where, h = 1m or H/4 è 1m or 0.75m = 1m [greater]

P = 9.81 (3 -1) =

19.62 kN/m2

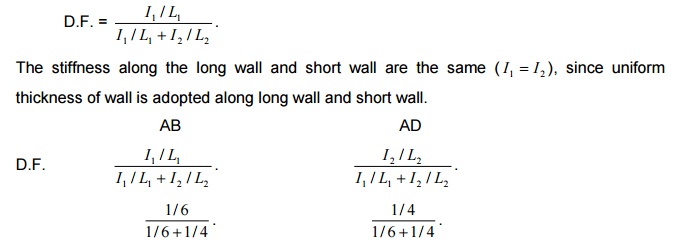

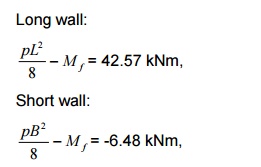

To find the final moment at

the junction of long wall and short wall based on the fixed end moment and

distribution factor, the moment distribution is done.

Joint A:

The stiffness along the long wall and short wall are the

same ( I1 =I 2 ),

since uniform thickness of wall is adopted along long wall and short wall.

Short wall is stiffer than the long wall.

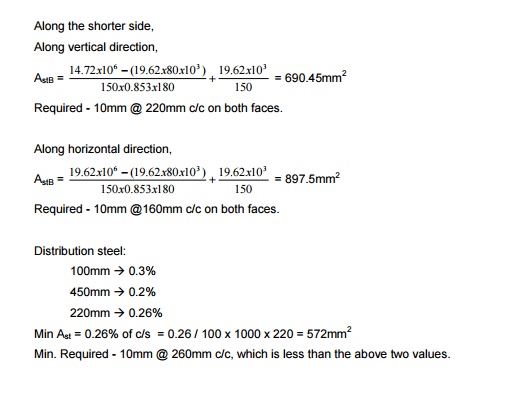

MFAB = pL2 / 12 = 19.62 x 62

/ 12 = 58.86 kNm (3p)

MFAD = pB2 / 12 = 19.62 x 42

/ 12 = 26.16 kNm (1.33p)

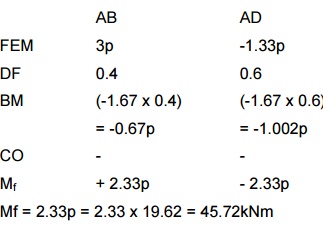

Joint A,

AB AD

FEM 3p -1.33p

DF 0.4 0.6

BM (-1.67 x 0.4) (-1.67 x 0.6) = -0.67p = -1.002p

CO - -

Mf + 2.33p - 2.33p

Mf = 2.33p = 2.33 x 19.62 = 45.72kNm

Moment at midspan,

The reinforcement is

provided for maximum moment generated. Therefore, maximum moment generated in

the water tank is 45.72kNm.

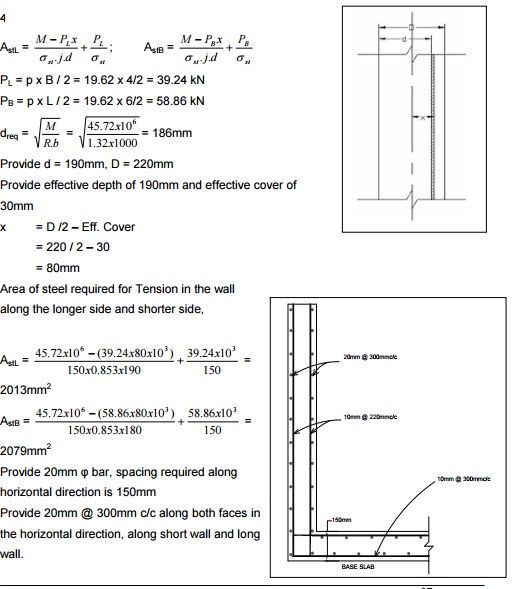

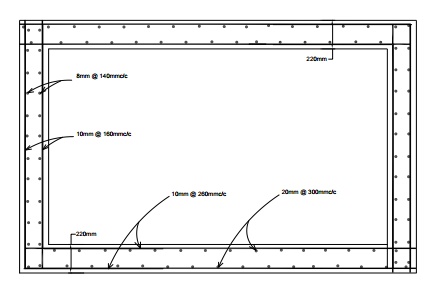

Provide 20mm spacing

? required bar, along horizontal direction is 150mm Provide 20mm @ 300mm c/c

along both faces in the horizontal direction, along short wall and long wall.

Min. Ast = 0.3% of c/s

= 0.3/100

x 1000 x 220

= 660

mm2

Spacing is provided for the

maximum of the above two [66mm2] Required, 10mm @ 110mm c/c

Provide, 10mm @ 220mm c/c as

vertical reinforcement along both the faces. For the base slab, provide a

nominal thickness of 150mm and minimum Ast of 0.3% of c/s.

Ast = 0.3/100 x

1000 x 150 = 450 mm2 Spacing of 10mm bars required = 170mm

Provide 10mm @ 300 mm c/c along both faces, both ways.

Provide 75mm lean mix with a

layer of tar felt which acts as a water bar, provided between the tank and lean

mix concrete.

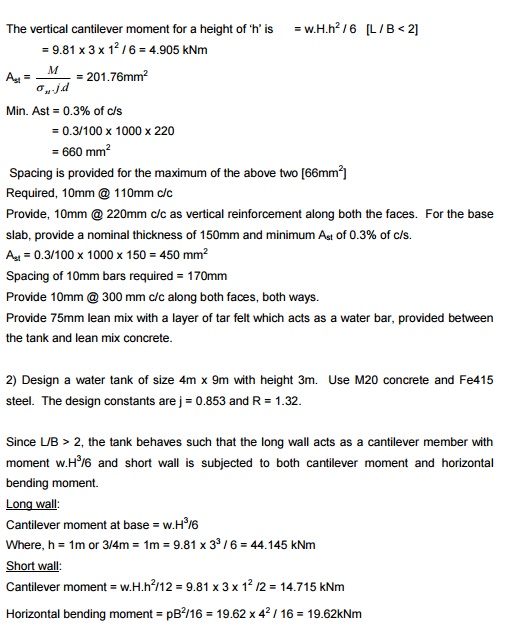

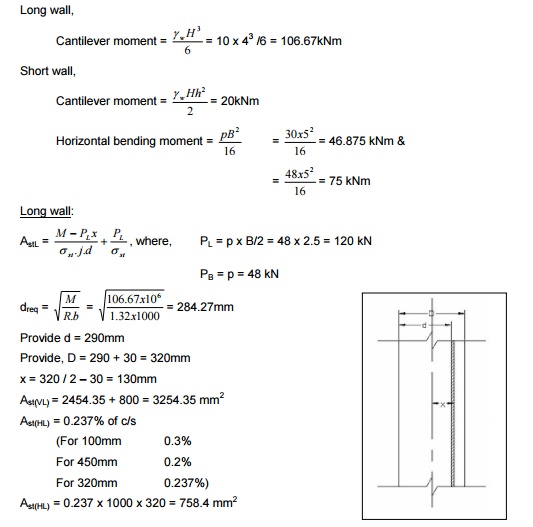

2) Design a water tank of

size 4m x 9m with height 3m. Use M20 concrete and Fe415 steel. The design

constants are j = 0.853 and R = 1.32.

Since L/B > 2, the tank

behaves such that the long wall acts as a cantilever member with moment w.H3/6

and short wall is subjected to both cantilever moment and horizontal bending

moment.

Long wall:

Cantilever moment at base = w.H3/6

Where, h = 1m or 3/4m = 1m =

9.81 x 33 / 6 = 44.145 kNm Short wall:

Cantilever moment = w.H.h2/12 = 9.81 x 3 x 12

/2 = 14.715 kNm

Horizontal bending moment =

pB2/16 = 19.62 x 42 / 16 = 19.62kNm (Where, p = w (H -h)

= 9.81 (3 -1) = 19.62kN/m)

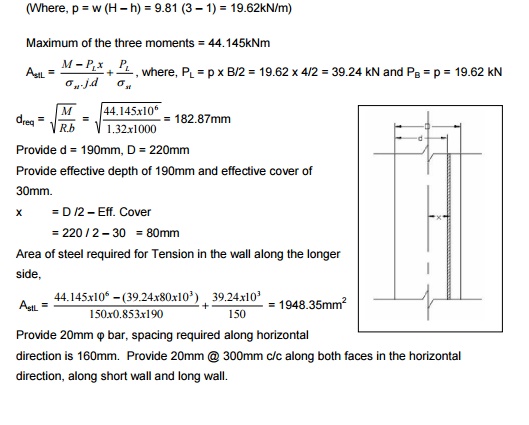

Maximum of the three moments

= 44.145kNm

Required - 10mm @160mm c/c on both faces.

Distribution steel:

100mm - > 0.3%

450mm - > 0.2%

220mm - > 0.26%

Min Ast = 0.26% of c/s = 0.26 / 100 x 1000 x 220 = 572mm2

Min. Required - 10mm @ 260mm c/c, which is less than the

above two values.

Base slab:

Since base slab is resting

directly on the ground, nominal thickness of 150mm is provided and minimum

reinforcement of 0.3% of cross-section is provided both ways along both faces.

Ast required =

0.3% of c/s = 465mm2. Provide 8mm @ 200mm c/c.

Below the base slab, a layer

of lean concrete mix is provided with 75mm thick tar felt layer between them.

DESIGN OF UNDERGROUND WATER TANK

Design of underground water

tank is similar to that of tanks resting on grounds (for rectangular water

tanks based on L/B ratio), where additional moment if any due to the earth

pressure on the side walls need to be considered. If the soil is submerged, pressure

exerted by water is also considered. Thus the side walls are checked for the

two critical conditions,

i) No earth pressure with wpressure(H-h) from wa

ii) Earth pressure exerted on wall under tank empty condition, -?pw)+?=H/3w.(?

The tank has to be checked

for uplift water pressure for which frictional resistance should be sufficient.

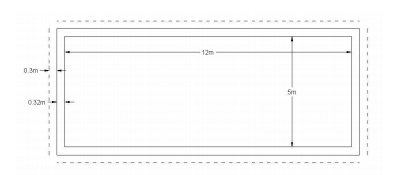

Design an underground water

tank of size 12m x 5m with height 4m. The density of soil is 16kN/m3

and coefficient of friction between soil and concrete is 0.15. The soil is

saturated. Here, L / B = 12 / 5 = 2.4 > 2

The tank walls are checked for two critical conditions,

i) No earth

pressure with wpressure(H-h) from

wa

= 10

(4-1) = 30kN/m2

ii) Earth pressure

exerted on wall

under-?w)+?wH

tank

= 48kN/m2

Where,

h = 1m or (H/4 = 1m)

Therefore, the maximum

pressure is used in finding out bending moment on the wall. Long wall,

Provide 10mm @ 200mm c/c

Short wall:

Ast(VL) = 370.8 + 320 = 690.8 mm2

< Astmin

Provide Astmin, 10mm @ 200mm c/c

Ast(HL) = 2173.09 mm2

Provide 16mm @ 180mm c/c

Check for uplift:

The tank is checked for

uplift pressure. When the uplift pressure exceeds the downward load due to the

self weight of the tank and the frictional resistance required. The base slab

is projected all around thereby increasing the downward load. The pressure of

submerged earth and water at the bottom of the base slab for 1m length of the

wall is found. The frictional resistance of the tank is found by multiplying

the coefficient of friction between soil and concrete with the pressure

exerted.

Assume the thickness of the

base slab as 400mm and provide a projection of 300mm all around the water tank.

Downward load due to self weight of tank:

Long wall = 2 x 12.64 x 0.32 x 4 x 25 = 808.36 kN

Short wall = 2 x 5 x 0.32 x 4 x 25 = 320 kN

Base slab = (12.64 + 0.6).(5.64 + 0.6) x 0.4 x 25 = 826.176kN

Total = 1955.136 kN

Weight of earth retained over projection,

Long wall = 2 x (12.54 + 0.6) x 4 x 0.3 x 16 = 508.42 kN

Short wall = 2 x 5.64 x 4 x 0.3 x 16 = 216.576 kN

= 724.996

kN

Total

load = 2680.132 kN

Frictional force required = 3635.174 -2680.132 = 955 kN

Pressure exerted by water at a depth of 4.4m,

p = H -/?w)3w.+H(?

= 4.43 (16

-10) + 10 x 4.4 = 52.8 kN/m2

![]()

Considering 1m length of wall, the force exerted is = ½ x

H x p

= ½ x 4.4 x 52.8 =

116.16kN/m The frictional resistance per metre length of wall = µ.F = 0.15 x 116.16 = 17.424 kN/m For the

entire perimeter of the wall, the frictional resistance offered,

= 2

x (12.64 + 5.64) x 17.42 = 637 kN < 955 kN

Hence the downward load due

to self weight and cantilever projection of bse slab is insufficient against

the uplift force. The length of projection has to be increased. Increase the

base projection to 0.7m, all around.

Downward load due to self weight of tank:

Long wall = 2 x 12.64 x 0.32 x 4 x 25 = 808.36 kN

Short wall = 2 x 5 x 0.32 x 4 x 25 = 320 kN

Base slab = (12.64 + 1.4).(5.64 + 1.4) x 0.4 x 25 = 988.416kN

Total = 2116.78 kN

Weight of earth retained over projection,

Long wall = 2 x (12.54 + 1.4) x 4 x 0.3 x 16 = 1257.98 kN

Short wall = 2 x 5.64 x 4 x 0.7 x 16 = 505.34 kN

= 1763.32

kN

Total

load = 3880.1 kN

Frictional force required = 4349.03 -3880 = 469.03 kN

< 637 kN

(Frictional force offered by walls)

p = 52.8 kN/m2.

The water tank is safe against uplift.

The base is design as a

continuous slab, supported between two short walls, for the self weight and

weight of side walls.

Design of base slab:

Loading on the base slab

includes the self weight of base slab and weight of side walls. Considering 1m

strip,

Weight of base slab = 7.04 x 0.4 x 25 = 70.4 kN/m

Weight of walls = 2 x 4 x 0.32 x 25 = 64

kN/m

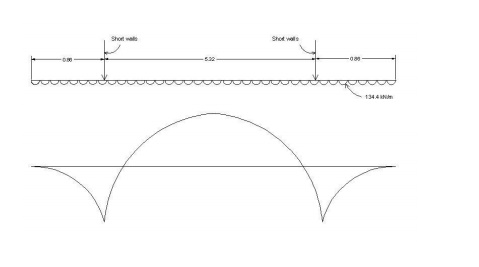

Total = 134.4 kN/m

Reaction at the support =

134.4 x 7.04 / 2 = 473.09 kN B.M. at the support = w.l2/2 = 134.4 x

0.862 / 2 = 49.7 kNm

B.M. at centre = 134.4 x

3.522 / 2 -473.09 (2.66) = -425.8kNm [sagging moment]

[D = 400mm, d = 400 -35 = 365mm] Provide 25mmø in two layers [both faces].

Provide 25mm @ 100mm c/c on

both faces.

Related Topics