Chapter: Civil : Design Of Reinforced Concrete And Brick Masonry Structures- Retaining Walls: Design of cantilever and counter fort retaining walls

Design Of Retaining Walls

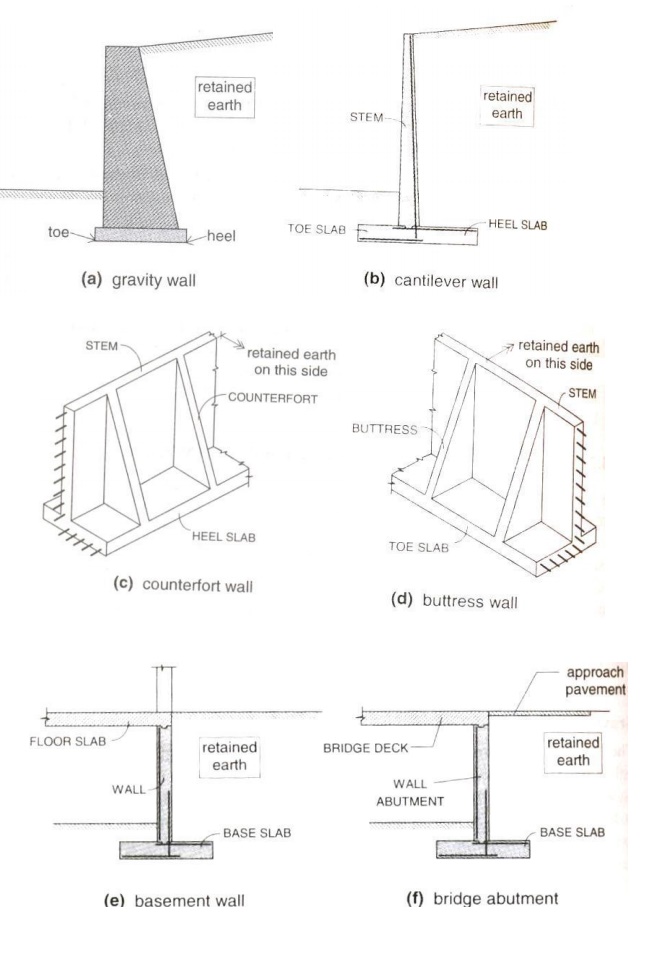

Retaining

wall -Retains Earth -when level difference exists between two surfaces

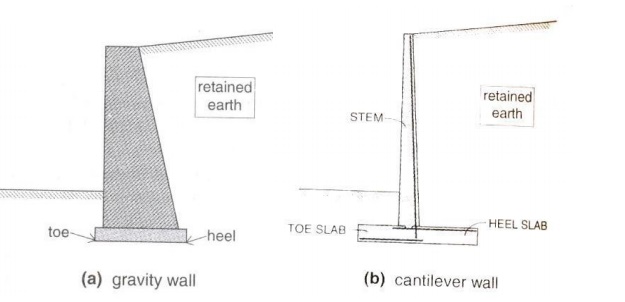

A) Gravity

wall (h<3m) -Masonry or Stone

B) Cantilever

wall (h>3m and h<6m)

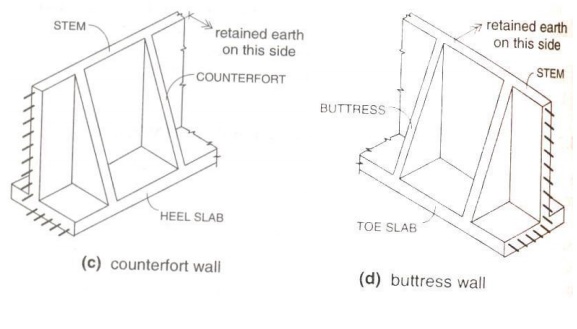

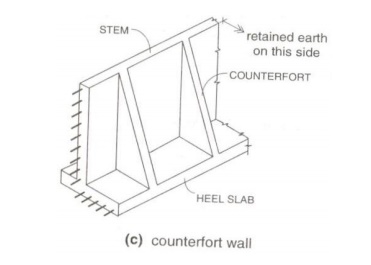

C) Counterfort

wall (h>8m)

D) Buttress wall [Transverse stem support

provided on front side]

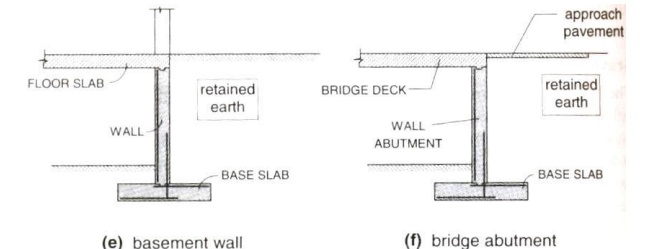

E)E) Bridge abutment [Additional horizontal restraint from bridge deck]

A) Gravity wall (h<3m) -Masonry or Stone

B) Cantilever wall (h>3m and h<6m)

C) Counterfort wall (h>8m)

D) Buttress wall [Transverse stem support provided on front side]

E)E) Bridge abutment [Additional horizontal restraint from bridge deck]

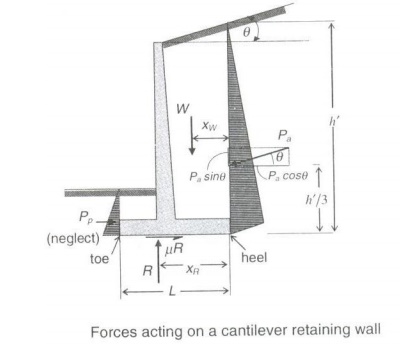

Stability -Overturning and Sliding -Avoided by providing sufficient base width.

Earth

pressure and stability requirements:

Pressure,

P

=CgZ

Where, Z = depth, g = Unit weight

Ca = 1

-Sinf / 1

+Sinf

Cp = 1 +Sinf / 1 -Sinf

Always, Cp > Ca.

Eg: If0, Ca?= 1/3=and30Cp = 3.

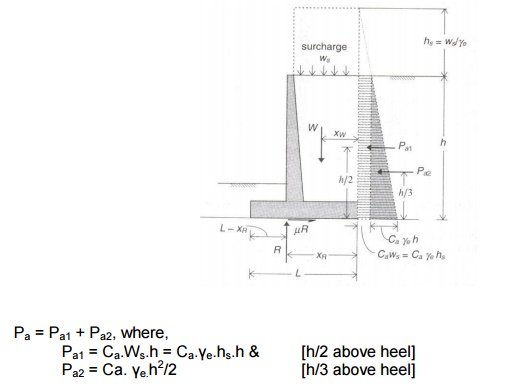

In sloped backfill,

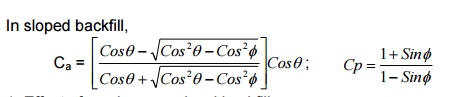

1.Effect of surcharge on

level backfill:

Pa = Pa1 + Pa2,

where,

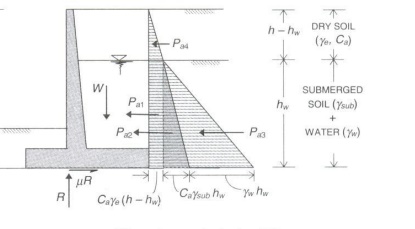

Note : Purpose of retaining wall

is to retain earth and not water. Therefore, submerged condition should be

avoided by providing and maintaining proper drainage facilities [including

provision of weep holes].

2. Effect of water in the

backfill:

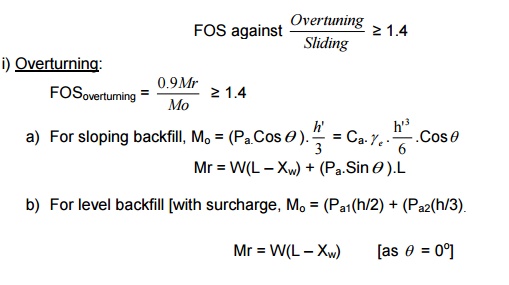

Stability requirements

ii)

Sliding: [Friction between base slab and supporting soil]

F = ?.[where,R R = W]

R

-> Resultant soil pressure at footing base

?->

Coefficient of static friction [0.35 -Silt & 0.60 -Rough rock]

FOSsliding

= 0.9F

/ Pa Cosq ?

1.4

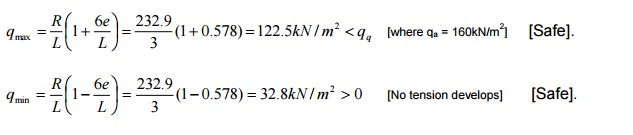

When Pa is very high, shear key

projection can be provided below footing base [Produces passive resistance Pps,

which is generally neglected, otherwise].

Sliding is reduced by

providing shear key [like a plug, anchors inside]

Pps =Cge(h2

2 -h12

)

/ 2

Xsk

-> Flexural reinforcement from stem is extended straight into shear key near

the

toe.

Note: For economical design,

soil pressure resultant(R) must be in line with front face of wall.

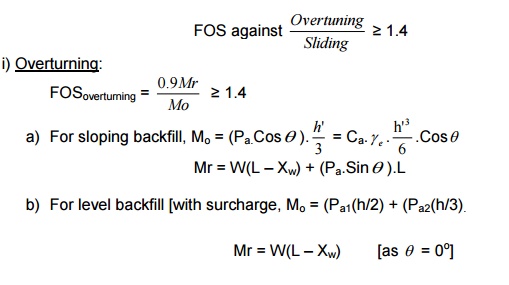

Preliminary

proportioning of cantilever retaining wall:

1. The

thickness of base slab is h/12 or 8% of the height of wall + surcharge.

2. The

base thickness of stem should be greater than the thickness of base slab

3. The

top thickness of stem should not be less than 150mm.

4. Clear

cover for stem is 50mm and base slab is

75mm

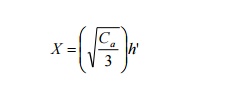

5. Minimum

length of base slab is given by

where,R=Coefficient?

depending on the pressure distribution

?R

= 0.5 for rectangular pressure distribution & 0.67 for trapezoidal pr.dist.

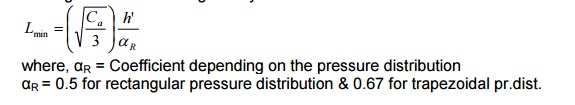

6. Minimum

length of heel slab is given by

Notes:

1. The

critical section for moment is at front face of stem.

2. The critical

section for shear

is at „d? f

3. The

stem, heel and toe slabs are designed as cantilever slabs for the resultant

pressure.

4. Temperature

and shrinkage reinforcement is provided as 0.12% of cross section along the

transverse direction to the main reinforcement and front face of the stem.

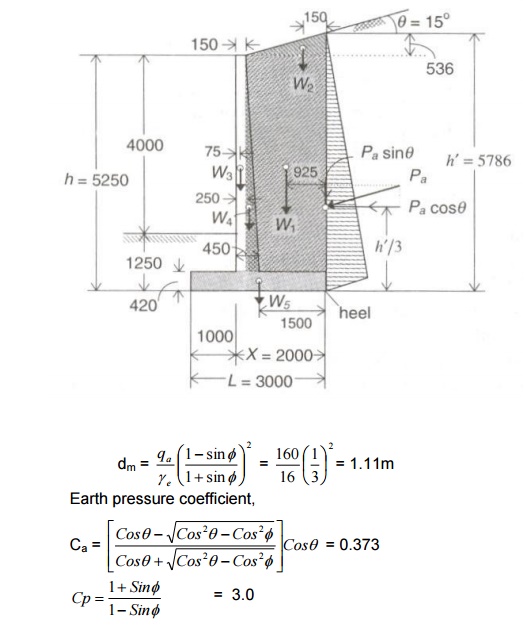

1. Determine suitable

dimensions of a cantilever retaining wall, which is required to support a bank

of earth 4.0m high above ground level on the toe side of the wall. Consider the

backfill surface to be inclined at an angle of 15o with the

horizontal. Assume good soil for foundation at a depth of 1.25m below ground

level with SBC of 160kN/m2. Further assume the backfill to comprise

of granular soil with unit weight of 16kN/m3 and an angle of

shearing resistance of 30o. Assume the coefficient of friction

between soil and concrete to be 0.5.

Given: h = 4.0 + 1.25m

? =o 15 ? = o 30

re = 16kN/m3

qa = 160kN/m2

? = 0.5

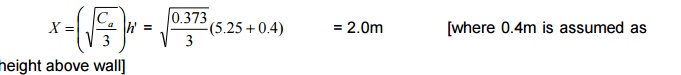

Minimum depth of

foundation (Rankine?s),

Preliminary

proportioning:

Thickness

of footing base slab = 0.08h = 0.08 x 5.25 = 0.42m

Provide

a base thickness of 420mm for base slab.

Assume

stem thickness of 450mm at base of stem tapering to 150mm at top of wall.

For economical proportioning

of length „L?, a be in line with front face of the stem.

height

above wall]

Assuming a triangular base

pressure distribution, L = 1.5X = 3.0m

Preliminary

proportions are shown in figure.

For the assumed proportions, the retaining

wall is checked for stability against overturning and sliding.

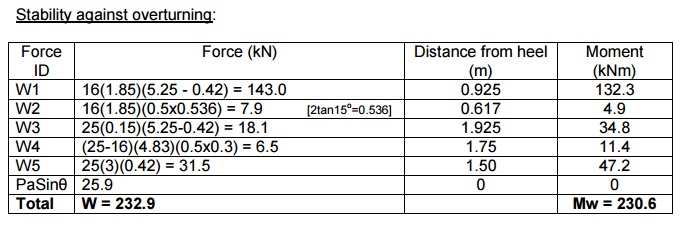

Stability against

overturning:

Pa = Active pressure exerted by retained

earth on wall [both wall and earth move in same direction]

Pp

= Passive pressure exerted by wall on retained earth [both move in opposite

direction]

Ca -> same for dry and

submerged condition, si significantly.

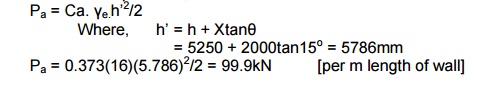

Force due to active pressure,

Pa = 0.373(16)(5.786)2/2 = 99.9kN [per

m length of wall]

FOS = 0.9

x Stabilising force

or moment / Destabilising force

or moment

Therefore,

FOS(overturning) = 0.9Mr / Mo ? 1.4

Overturning moment, Mo

= (PaCos?)h?/3 = 96.5(5.786/3) =

186.

To find the distance of

resultant vertical force from heel,

Distance

of resultant vertical force from heel,

Xw

= Mw/W = 230.6/232.9 = 0.99m

Stabilising

moment (about toe),

Mr = W(L -Xw)

+ PaSin?(L) =-0 .99)232+77.69(3 = 468.1kNm [per m length of wall]

FOS(overturning) = 0.9Mr

/ Mo = 0.9x(468.1 +77.6) / 186.1 = 2.26 > 1.40

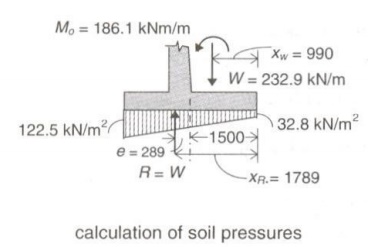

Soil

pressure at footing base:

Resultant vertical reaction,

R = W = 232.9kN [per m length of wall]

Distance

of R from heel, LR = (Mw + Mo) / R = (230.6 +

186.1)/232.9 = 1.789m

Eccentricity,

e = LR -L/2 = 1.789 -3/2 = 0.289m < L/6 ->[0.5m]

Hence

the resultant lies within the middle third of the base, which is desirable.

Maximum pressure as base,

Stability

against sliding:

Sliding force, PaCos? =

96.5kN

Resisting force, F

= ?R =[Ignoring0 .passive5 pressurex232ontoe.side]9 =

116.4

FOS(Sliding) = 0.9F

/ Pa Cosq = 0.9x116.4 / 96.5

= 1.085 <1.40 [Not sufficient]

Hence

a shear key may be provided.

Assume a shear key 300mm x

300mm at a distance of 1300mm from toe as shown in figure.

h2 = 950 + 300 + 1300tan30o = 2001mm

Pp = Cp.e?.(h22

-h12)/2 = 3 x 16 x (2.0012 -0.9502)/2

= 74.11kN.

FOS (Sliding) = 0.9(116.4

+74.44) / 96.5 =1.78 >1.4

[SAFE]

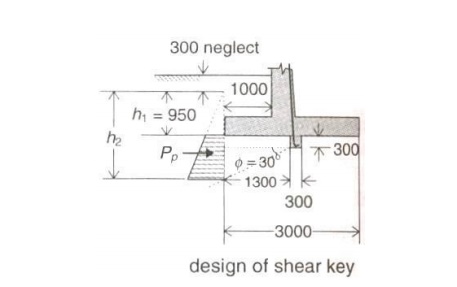

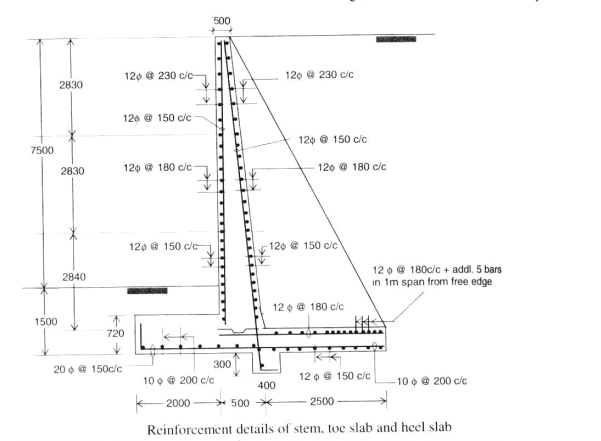

Design of toe slab:

Assuming a clear

cover of 75mm

and 16mm ?

use

d

= 420 -75 -8 = 337mm

Vu

= 1.5 [112 +81.9 / 2] x(1 - 0.337) =

96.42kN [Vu is

design shear at

„d? from fac

Mu = 1.5{(81.9 x

12/2) + (112 - 81.9) x 1/2 x 12 x

2/3} = 76.48 kNm/m length

Nominal shear stress, t = V/ bd = 96.42x103

/ 1000x337 =0.286N

/ mm2

Using M20

concrete,

For a t =0.29N/mm2,

pt (required) = 0.2%

K = M u bd 2 = 76.48x106

/ 1000x3372 =0.673N / mm2

For pt = 0.2%, Ast

= 0.2/100 x 1000 x 337 = 674 mm2 / m

Spacing

= ( 1000xpx162 / 4 )

/ 674 =

298mm

Provide

16mmf @ 290mm c/c at bottom of

toe slab

Ld

= fs s / 4t bd = (16).0.87

f y / 4t

bd = 752mm, beyond face of stem.

Since

length available is 1m, no curtailment is sorted.

Design

of heel slab:

Vu = =128.06kN

Mu

= 1.5{(82.54 x 1.552/2) + (128.6 - 82.54) x 1/2 x 1.552 x

2/3}

= 203.96 kNm/m length

Nominal

shear stress, t = V / bd = 128.06x103

/ 1000x337 = =0.38N / mm2

Using M20 concrete,

For a t =0.39N/mm2,

pt (required) = 0.3%

K = M u / bd 2 = 203.96x106

/ 1000x3372 = 1.8N

/ mm2

For pt = 0.565%,

Ast = 0.565/100 x 1000 x 337 = 1904.05 mm2 / m

Spacing

= (1000xpx162 / 4) / 1904.05

=

105.61mm

Provide

16mmf @ 100mm c/c at bottom of

toe slab

Ld

= fs s

/ 4t bd

= (16).0.87 f y / 4tbd

= 16 x 47 = 752mm, beyond face of stem.

Since

length available is 1.55m, no curtailment is sorted.

Design

of vertical stem:

Height

of cantilever above base = 5250 -420 = 4830mm

Assume a clear cover of 50mm and 16mm? bar, dat

base = 450 -50 -16/2 = 392mm

Mu

= 1.5(Ca.e?.h3/6) = 1.5(1/3)(16 x 4.923/6)

= 150.24kNm.

K

= Mu

/ bd2 = 150.24x106

/ 1000x4.922 = 1N/mm2

pt = 0.3%, Ast =

0.295/100 x 1000 x 392 = 1200mm2. Spacing = 1000 x 201/1200 = 160mm

Provide

16mmf @ 160mm

c/c in the

stem, extending= int

752mm.

Check for shear: [at „d?

from base]

Vu (stem) = 1.5(Ca.e?.Z2/2)

= 1.5(1/3 x 16 x (4.83 -0.392)2/2) = 53.83kN

tv=

Vu / bd = 53.83x103 / 1000x392

= =0.135N / mm2 <tc

[where,c=0.39N/mm?2

for pt = 0.3%))

Hence,

SAFE.

Curtailment

of bars:

Curtailments

of bars in stem are done in two stages:

At

1/3rd and 2/3rd height of the stem above base.

Temperature

and shrinkage reinforcement:

Ast = 0.12/100 x

10 x 450 = 540mm2

For I 1/3rd height, provide 2/3rd

of bar near front face (exposed to weather) and 1/3rd near rear

face.

For II 1/3rd height, provide 1/2

the above. For III 1/3rd height, provide 1/3rd of I case.

Provide nominal bars of 10mm

@ 300mm c/c vertically near front face.

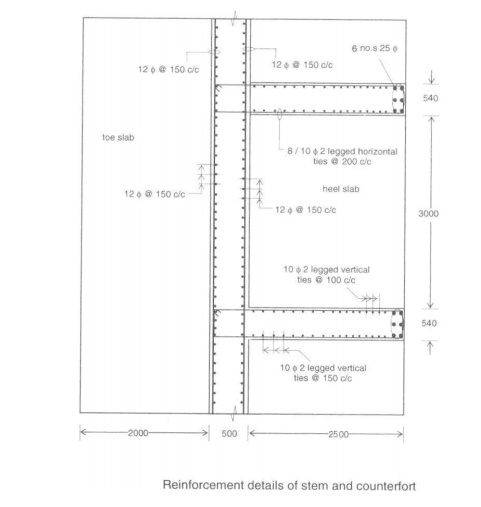

DESIGN OF COUNTERFORT

RETAINING WALL

Preliminary

proportioning of counterfort retaining wall:

1. Thickness

of heel slab and stem = 5% of Height of wall

2. Thickness

of toe slab [buttress not provided] = 8% of Height of wall

3. Thickness

of counterfort = 6% of height of wall

4. In

no case thickness of any component be less than 300mm.

5. Spacing

of counterforts = 1/3rd to 1/2

of Height of wall

6. Each

panel of stem and heel slab are designed as two way slab with one edge free

(one way continuous slab).

7. The

toe slab is designed as

a. Cantilever

slab when buttress is not provided

b. One

way continuous slab, when buttress is provided

8. Counterfort

is a triangular shaped structure designed similar to a T-Beam as vertical

cantilever with varying depth (stem acts as flange). The main reinforcement is

along the sloping side. Stirrups are provided in the counterfort to secure them

firmly with the stem. Additional ties are provided to securely tie the

counterfort to the heel slab.

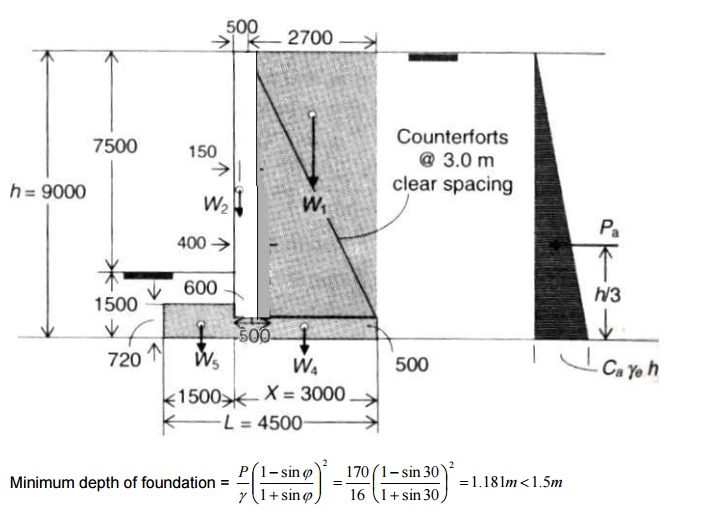

1) Design a suitable counterfort retaining

wall to support a leveled backfill of height 7.5m above ground level on the toe

side. Assume good soil for the foundation at a depth of 1.5m below ground

level. The SBC of soil is 170kN/m2 with unit weight as 16kN/m3.

The angle of internal

friction.Thecoefficientof isfriction ?between=30thesoil and concrete is 0.5.

Use M25 concrete and Fe415 steel.

Depth of foundation = 1.5m

Height of wall =

7.5 + 1.5 = 9m

Thickness of heel

and stem =

5% of 9m

= 0.45m

Thickness of toe slab = 8%

of 9m = 0.72m

Lmin

= 1.5 x 3 = 4.5m

Thickness

of counterfort = 6% of 9 = 0.54m

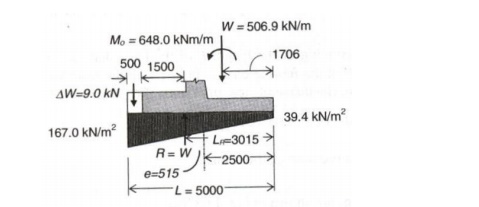

Stability Condition:

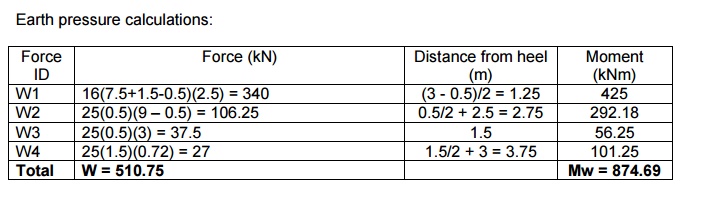

Earth pressure calculations:

Xw = 874.69/510.75 = 1.713m

FOS (overturning) = 0.9Mr/Mo

Where

Mo = Pa.h/3 = Ca.e?.h3/6

= 0.33x16x93/6 = 647.35kNm.

Mr = (L -Xw).W = 510.75(4.5

-1.713) = 1423.6kNm.

FOS (overturning) = 1.98

> 1.4

Hence, section is safe against overturning.

Sliding:

FOS (sliding)

= 0.9(?R)/PaCos?

F = ?R

= 0.5 x

510.75 = 255.375kN

Pa = Ca.e?.h2/2

= 215.784

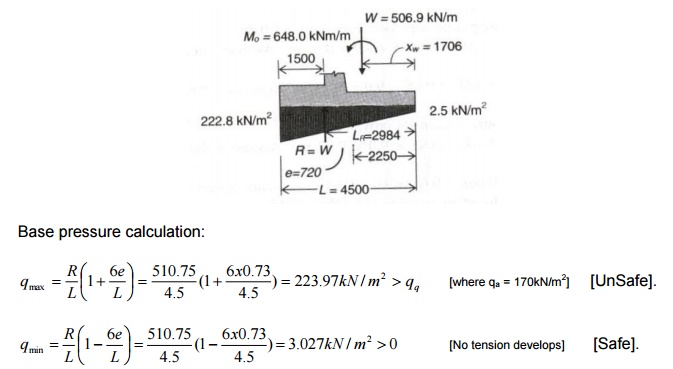

Where, LR = (M + Mo)/R,

e = LR -L/2, where, LR = (874.688 + 647.352)/510.75 =

2.98m

&

e = LR -L/2 = 2.98 -(4.5/2) = 0.73 < L/6 à

(0.75m)

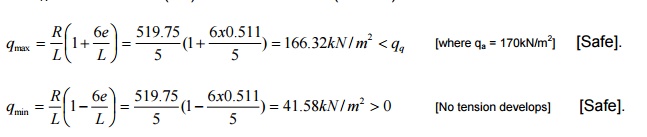

Since the maximum earth pressure is greater

than SBC of soil, the length of base slab has to be increased preferably along

the toe side. Increase the toe slab by 0.5m in length.

?W = 510.75

+ 0.5 x

25 x 0.72

= 519.75kN

Additional load due to increase in toe slab

by 0.5m is, Moment = 0.5/2 + 4.5 = 4.75m

?M = 874.69

+ 42.75 =

917.438kNm.

LR = (Mo + M) / R = (917.438 + 647.352)/519.75 = 3.011m

e= LR -L/2 = 3.011 -(5/2) = 0.511m < L/6 - > (0.833m)

FOS (Sliding) = 0.9(?R)/Pa=0.9(0.5x519.75)/215.784

= 1.08 < 1.4.

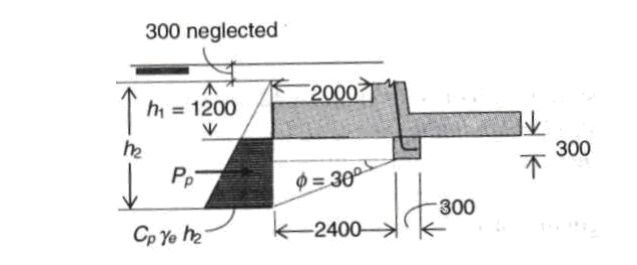

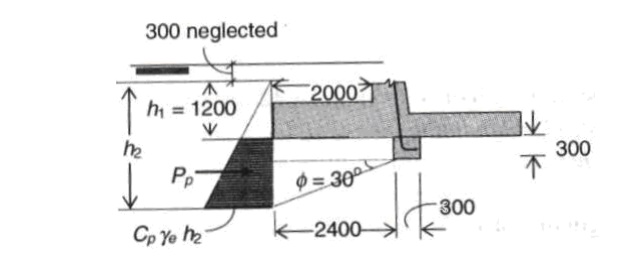

Hence the section is not safe against

sliding. Shear key is provided to resist sliding. Assume shear key of size 300

x 300mm.

Pps = Cp.e?.(h22

-h12)/2 = 164.5kN/m

FOS (sliding) = 0.9(?Rps)/Pa =

+1.77P> 1.4 [where,

h1 = 1.2m, h2 = 1.2 + 0.3 + 1.39 = 2.88m]

Hence, section is safe in sliding with shear

key 300 x 300mm.

Design of Toe Slab:

Effective cover = 75 + 20/2 = 85mm

Toe slab is designed similar to cantilever

slab with maximum moment at front face of the stem and maximum shear

at„d?fromfront face of stem.

d = 720 -85 = 635mm.

M = 80.38x22/2 + ½ x 2 x 49.94 x

2/3 x 2 = 160.76 + 122.76 = 227.35kNm.

SF at 0.635m, = 49.94/2 x 0.635 = 15.606kN

Area of trapezoid = ½.h.(a + b) = ½(2

-0.635)(130.32 + 95.98) = 154.44kN

Factored SF = 231.66kN; Factored Moment =

341.02kNm.

K = Mu/bd2

à Ast = 1551.25mm2 à Spacing

= 1000ast/Ast à 16mm @125mmc/c.

Transverse reinforcement: = 0.12% of c/s

= 0.12/100 x 1000 x 720 = 864mm2

Provide 10mm @100mm c/c.

Design of heel slab:

The heel slab is designed as an one way

continuous slab with moment wl2/12 at the support and wl2/16

at the midspan. The maximum shear at the support is w(l/2 -d). The maximum

pressure at the heel slab is considered for the design.

Moment at the support, Msup = wl2/12

= 106.92 x 2.52/12 = 55.688kNm.

Moment at the midspan, Mmid = wl2/16

= 41.76kNm

The maximum

pressure acting on

the heelstrequiredslabat

midspan and support are found.

Factored Msup =

83.53kNm à Ast = 570.7mm2

Factored Mmid =

62.64kNm à Ast = 425.4mm2

Using

16mm ? bar,

Spacing à=Provide1000ast16mm@110mm/Astc/c

At midspan, spacing = 156.72mm à Provide 16mm @ 150mm c/c

Transverse reinforcement = 0.12% of c/s =

0.12/100 x 1000 x 500 = 600mm2

For 8mm bar, Spacing = 83.775mm à

Provide 8mm @80mm c/c.

Check for shear:

Maximum shear = w (l/2 -d) = 107 (2.5/2

-0.415) = 89.345kN

Factored shear force = 134.0175kN

?v = 0.33N/mm , ?c

= 0,.29N/mm?cmax =

3.1N/mm

Depth has to be increased. Design of stem:

The stem is also designed as

one way continuous slab with support moment wl2/12 and midspan

moment wl2/16. For the negative moment at the support, reinforcement

is provided at the rear side and for positive moment at midspan, reinforcement

is provided at front face of the stem.

The maximum moment varies from a base intensity of Ka.e?.h=1/3x16x(9-0.5)=

45.33kN/m Msup = wl2/12 = 1.5 x 45.33 x 3.542/12

= 71kNm

Mmid = wl2/16 = 1.5 x 45.33 x 3.542/16

= 53.26kNm Effective depth = 500 -(50 + 20/2) = 440mm

Ast at support = 1058mm2, For

16mm ?,190mmSpacing.Provide16mm

=@ 190mm c/c

Ast at midspan =718mm2, For 16mm

?,280mmSpacing.Provide16mm@280mm= c/c Max. SF = w (l/2 -d) = 60.29kN, Factored

SF = 90.44kN

Transverse reinforcement = 0.12% of c/s à 8mm @ 80mmc/c

?v = 0.188N/mm2,c

=?0.65N/mm2,cmax?= 3.1N/mm2 Safe in Shear. Design

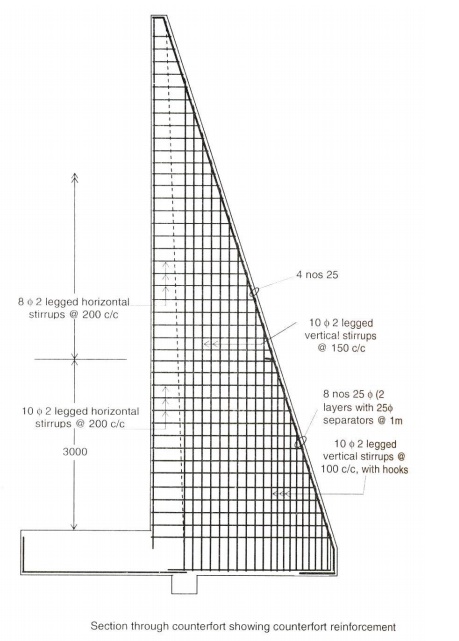

of Counterfort:

The counterfort is designed as a cantilever beam whose

depth is equal to the length of the heel slab at the base and reduces to the

thickness of the stem at the top. Maximum moment at the base of counterfort, Mmax

= Ka.e?.h3/6 x Le

Where, Le à c/c

distance from counterfort

Mmax = 1932.5kNm, Factored Mmax = 2898.75kNm

Ast = 2755.5mm2, Assume 25mm?bar,

No. of bars required = 2755.5/491.5 = 5.61 ~ 6 The main reinforcement is

provided along the slanting face of the counterfort. Curtailment of

reinforcement:

Not all the 6 bars need to be taken to the

free end. Three bars are taken straight to the entire span of the beam. One bar

is cut at a distance of, n -1/8.5 = h12/8.52 , where

n is the total number of bars and h1 is the distance from top. N

When n = 6, h1 = 7.75m [from bottom]

The second part is cut at a distance of,

n -2/ n = h2/8.52 , h2=6.94m [from bottom]

The third part is cut at a distance of,

n -3/ n = h32/8.52 , h3=6. 01m [from bottom]

Vertical ties and horizontal

ties are provided to connect the counterfort with the vertical stem and the

heel slab.

Design of horizontal ties:

Closed stirrups are provided

to the vertical stem and the counterfort. Considering 1m strip, the tension

resisted by reinforcement is given by lateral pressure on the wall multiplied

by contributing area.

T = Ca.e?.h x h, where, Ast = 1/ 0.87

fy

T = 1/3 x 16 x (9 -0.5) x 3.54 = 160.48kN Factored force,

T = 1.5 x 160.48kN

Ast = 666.72mm2. For 10mm ?,

Spacing110mm. =

Provide 10mm@110mm c/c closed stirrups as horizontal

ties. Design of vertical ties:

The vertical stirrup

connects the counterfort and the heel slab. Considering 1m strip, the tensile

force is the product of the average downward pressure and the spacing between

the counterforts. T = Avg(43.56 & 107) x Le = 266.49 kN

Factored

T = 399.74 kN

Ast = 1107.15mm2. For 10mm

?, Spacing70.93mm. =

Provide 10mm @ 70mm c/c.

Related Topics