Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Track Maintenance

Deep Screening of Ballast

Deep Screening of Ballast

Deep screening of the ballast is

done to ensure that a clean ballast cushion of the required depth is available

below the lower half of the sleepers, which is necessary for providing the

proper drainage and elasticity to the track. In the absence of a clean ballast

cushion of the desired depth, track geometry may get disturbed, affecting the

performance of the track.

Deep screening is normally

carried out under speed restrictions without obtaining a traffic block. It is

desirable to proceed with deep screening in a direction opposite to that of the

traffic. An adequate quantity of ballast, the necessary equipment and tools,

and the required labour should all be arranged well in time. Work should not be

carried out during monsoons. The procedure for deep screening is as follows.

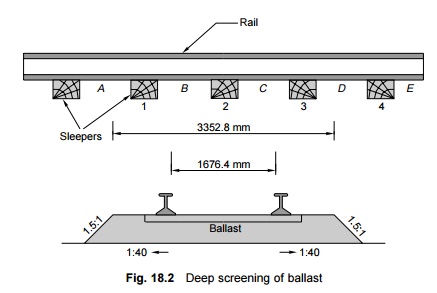

(a) A group

of four sleepers are tackled one at a time in sequence. As shown in Fig. 18.2,

each of the sleepers (numbered 1, 2, 3, and 4, etc.) is tackled individually.

(b) The

ballast from spaces A and B is removed right down to the formation and wooden

blocks are put in its place to support the track. Precautions are taken to

avoid digging out the consolidated top of the formation.

(c) The

ballast is removed from under sleeper 1, screened, placed under the same

sleeper, packed.

(d) The

wooden block is removed from space A.

(e) The

ballast from space C is removed and placed after screening in space A. If

additional ballast is required, it may be taken from the extra ballast trained

out in advance along the side of the track.

(f) The

wooden block that was removed from space A is placed in space C. Sleeper 2 is

provided with wooden blocks on either side in order to support the track.

(g) The

ballast under sleeper 2 is removed, a screened ballast is provided in its

place, and the sleeper is packed.

(h) Ballast

from space D is removed, screened, and placed in space B. Any extra ballast

that my be needed is taken from the track.

(i) The

wooden block from space B is removed and put in space D to support the rail.

(j) The

procedure is repeated till the work is completed.

It can be seen from this procedure

that work is done in such a way that when the ballast is being excavated from

under one sleeper, there are at least four sleepers between this sleeper and

the next sleeper that is being worked upon. The track is also lifted, if

required. This should only be done at a rate of 50 mm (2") at a time. It

should be ensured that the packing, cross level, and grading-off are

satisfactory before closing the day's work.

Deep screening is done under a

speed restriction of 15 km/h. This speed can be released to normal speeds in

the following ways.

Manual packing By manual

packing four times in succession and by picking up slacks over a

period of 21 days.

Machine packing Packing

with the help of tie machines, by tamping the track thrice

followed by picking up slacks over a period of 10 days.

Related Topics