Chapter: Civil : Design of Reinforced Concrete Elements : Limit State Design For Flexure

Cracking in structural members

Cracking

in structural members

Cracking of concrete occurs

whenever the tensile stress developed is greater than the tensile strength of

concrete. This happens due to large values of the following:

1. Flexural

tensile stress because of excessive bending under the applied load

2. Diagonal

tension due to shear and torsion

3. Direct

tensile stress under applied loads (for example hoop tension in a circular

tank)

4. Lateral

tensile strains accompanying high axis compressive strains due to Poisson's

effect (as in a compression test)

5. Settlement

of supports

In

addition to the above reasons, cracking also occurs because of

1. Restraint

against volume changes due to shrinkage, temperature creep and chemical

effects.

2. Bond and

anchorage failures

Cracking spoils the aesthetics of

the structure and also adversely affect the durability of the structure.

Presence of wide cracks exposes the reinforcement to the atmosphere due to

which the reinforcements get corroded causing the deterioration of concrete. In

some cases, such as liquid retaining structures and pressure vessels cracks

affects the basic functional requirement itself (such as water tightness in

water tank).

Permissible crack width

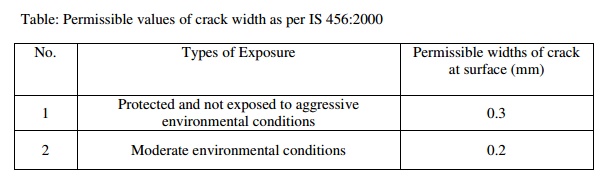

The

permissible crack width in structural concrete members depends on the type of

structure and the exposure conditions. The permissible values are prescribed in

clause 35.3.2 IS 456:2000 and are shown in table below

Table:

Permissible values of crack width as per IS 456:2000

Control

of cracking

The check for cracking in beams are done through

the following 2 methods specified in IS 456:2000 clause 43.1

1. By empirical method:

In this method, the cracking is said to be in

control if proper detailing (i.e. spacing) of reinforcements as specified in

clause 26.3.2 of IS 456:2000 is followed. These specifications regarding the

spacing have been already discussed under heading general specifications. In

addition, the following specifications shall also be considered

i. In the

beams where the depth of the web exceeds 750 mm, side face reinforcement shall

be provided along the two faces. The total area of such reinforcement shall not

be less than 0.1% of the web area and shall be distributed equally on two faces

at a spacing not exceeding 300 mm or web thickness whichever is less. (Refer

clause 25.5.1.3 IS456:2000)

ii. The

minimum tension reinforcement in beams to prevent failure in the tension

zone by

cracking of concrete is given by the following

As

= 0.85 fy / 0.87 fy

(Refer clause 26.5.1.1 IS 456:2000)

iii. Provide

large number of smaller diameter bars rather than large diameter bars of the

same area. This will make the bars well distributed in the tension zone and

will reduce the width of the cracks.

2. By crack

width computations

In the

case of special structures and in aggressive environmental conditions, it is

preferred to compute the width of cracks and compare them with the permissible

crack width to ensure the safety of the structure at the limit state of

serviceability. The IS 456-2000 has specified an analytical method for the

estimation of surface crack width in Annexure-F which is based on the British

Code (BS : 8110) specifications where the surface crack width is less than the

permissible width, the crack control is said to be satisfied.

Related Topics