Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Process Planning and Concurrent Engineering

Concurrent Engineering and Design for Manufacturing

CONCURRENT ENGINEERING AND DESIGN FOR MANUFACTURING

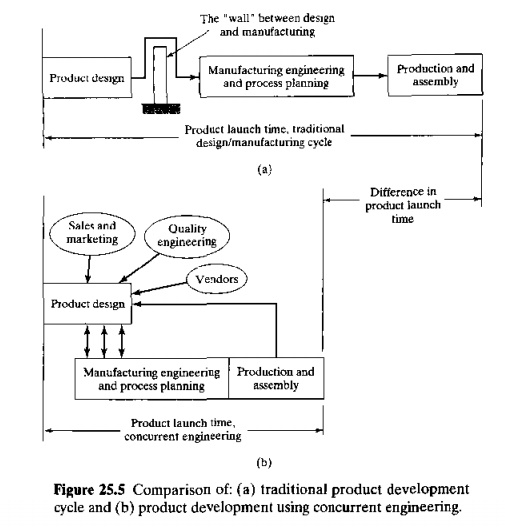

Concurrent engineering refers to

an approach used in product development in which the functions of design engineering, manufacturing engineering, and

other functions are integrated to reduce the elapsed time required to bring a

new product to market. Also called simultaneous

engineering, it might be thought of as the organizational counterpart to CAD/CAM technology. In the traditional

approach 10 launching a new product, the two functions of design engineering

and manufacturing engineering tend to be separated and sequential. as

illustrated in Figure 25.5(a). The product design department develops the new

design, sometimes without much consideration given to the manufacturing

capabilities of the company. There is little opportunity for manufacturing

engineers to offer advice

Figure 15.5

Comparison of: (a) traditional product development cycle and (b) product development using concurrent engineering.

on how

the design might be altered to make it more manufacturable. It is as if a wall

exists between design and manufacturing. When the design engineering department

completes the design, it tosses the drawings and specifications over the wall,

and only then does process planning begin.

By

contrast, in a company that practices concurrent engineering, the manufacturing

engineering department becomes involved in the product development cycle early

on, providing advice on how the product and its components can be designed to

facilitate manufacture and assembly. It also proceeds with the early stages of

manufacturing planning for the product. This concurrent engineering approach is

pictured in Figure 2S.5(b). In addition 10 manufacturing engineering, other

functions are also involved in the product development cycle, such as quality

engineering, the manufacturing departments, field service, vendors supplying

critical components, and in some cases the customers who will use the product.

AU of these functions can make contributions during product development to

improve not only the new product's function and performance, but also its produce

ability. inspectability, testability, serviceability, and maintainability.

Through early involvement, as opposed to reviewing the final product design

after it is too late to conveniently make any changes in the design, the

duration of the product development cycle is substantially reduced.

Design for

Manufacturing and Assembly

It has

been estimated that about 70% of the life cycle cost of a product is determined

by basic decisions made during product design. These design decisions include

the material for each part. part geometry, tolerances, surface finish, how

parts are organized into subassemblies. and the assembly method, to he used. Once these decisions are

made, the ability to reduce the manufacturing cost of the product is limited. For example.

if the product designer decides that a part is to be made of an aluminum sand

casting but which possesses features that can he achieved only h) machining (such as threaded

holes and close tolerances). the manufacturing engineer has no alternative

except to plan a process sequence that starts WIth sand casting followed by the sequence of machining

operations needed to achieve the specified features. In this example, a better

decision might be to use a plastic molded part that can be made in a single

step. It is important for the manufacturing engineer to be given the

opportunity to advise the design engineer as the product design is evolving, to

favorably influence the manuacturability of the product.

Terms used

to describe such attempts to favorably influence the rnanufacturability of a

new product are design .for manufacturing

(DFM) and design for assembly (DFA).

Of course, DFM and DFA arc inextricably linked, so let us use the term design for manufacturing and assembly (DFMIA).

Design for manufacturing and assembly involves the systematic consideration of

rnanufacturability and assemblability in the development of a new product

design. This includes: (l)

organizational changes and (2) design principles and guideline,

Organizational Changes in DFMIA. Effective

implementation of DFMlA, involves making

changes in a company's organizational structure. either formally or informally,

so that closer interaction and better communication occurs between design and manufacturing

personnel. This can he accomplished in several ways: (1) by creating project

teams consisting of product designers, manufacturing engineers, and other

specialties (e.g., quality engineers, material scientists) to develop the new

product design; (2) by requiring design engineers to spend some career time in

manufacturing to witness firsthand how manufacturabihty and assemblability are

impacted by a product's design; and (3) by assigning manufacturing engineers to

the product design department on either a temporary or fulltime basis to serve

as producibility consultants.

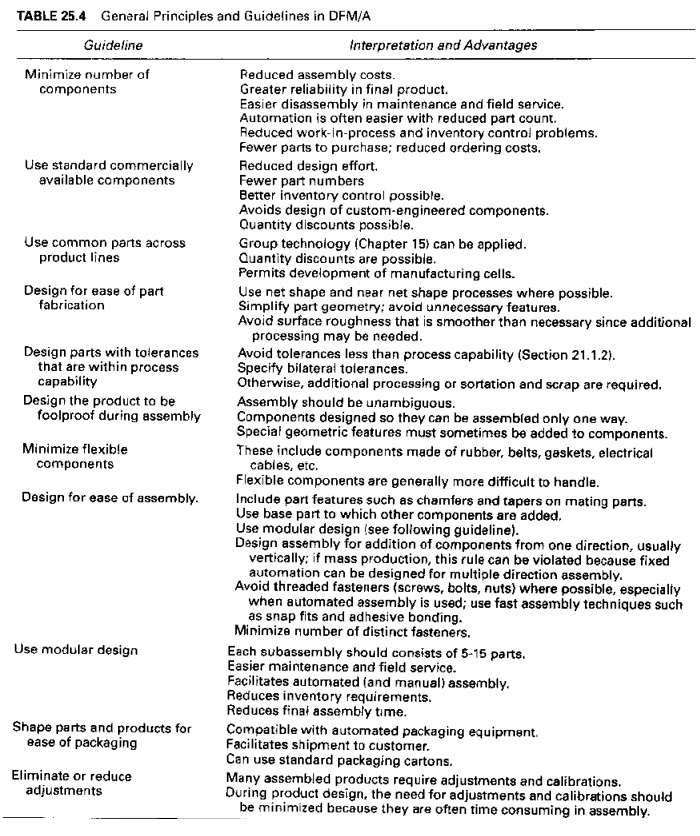

Design Principles and Guidelines. DFM/A also relies on the use

01 design principles and guidelines for

how 10 design a given product to maximize manufacturability and

asscrnblability. Some of these arc universal design guidelines that can be applied

to nearly any product design situation, such as those presented in Table 25.4.

In other cases, there are design principles that apply to specific processes,

for example, the use of drafts or tapers in casted and molded parts to

facilitate removal of the part from the mold, We leave these more process-specific

guidelines to texts on manufacturing processes, such as .

The guideline.

sometimes conflict with one another. for example. one of the guidelines in

Table 25.4 is to "simplify part geometry; avoid unnecessary

features." But another guideline in the

same table states that "special geometric features must sometimes be added

to components" to design the product for foolproof assembly. And it may also be desirable to

combine features of several assembled parts into one component to minimize the

number of parts in the product. In these instances. design for part manufacture

is in conflict with design for assembly, and a suitable compromise must be

found between the opposing sides of the conflict.

Other

Product Design Objectives

To

complete our coverage of concurrent engineering, let us hriefly discuss the

other design objectives: design for quality, cost, and life cycle.

Design

for Quality. It might be argued that DFM/A is the most important component

of concurrent engineering because it has the potential for the greatest impact

on product cost and development time. However. the importance of quality in

international competition cannot be minimized. Quality does not just happen. It

must be planned for during product design and during production. Design for quality (DFQ) is the term

that refers to the principles and procedures employed to ensure that the

highest possible quality is designed into the product. The general objectives

of DFQ are [1]: (1) to design the product to meet or exceed customer

requirements; (2) to design the product to be "robust," in the sense

of Taguchi (Section 20.3.2), that is, to design the product so that its

function and performance are relatively insensitive to variations in

manufacturing and subsequent application; and (3) to continuously improve the

performance, functionality. reliability, safety. and other quality aspects of

the product to provide superior value to the customer.

Our

discussion of quality in Part IV (Chapters 2023) is certainly consistent with

the focus of design for quality, but our emphasis in those chapters was

directed more at the operational aspects of quality during production. Among

those chapters, the Taguchi quality engineering methods (Section 20.3) are

applicable ill design

for quality. Another approach that is gaining acceptance is quality function

deployment, discussed in Section 24.5.

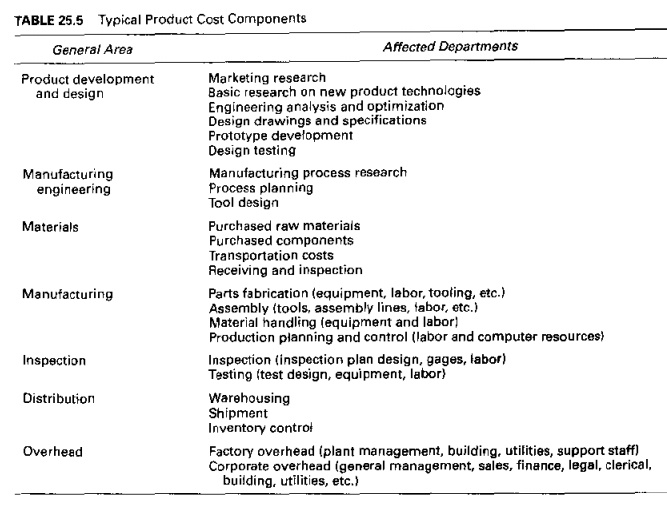

Design

for Product Cost. The cost of a product is a major factor in

determining its commercial success, Cost affects the price charged for the product

and the profit made by the company producing

it. Design for product cost (DFC) refers to the efforts of a company to

specifically identify how design decisions affect product costs and to develop

ways to reduce cost through design. Although the objectives of DFC and DFMIA

overlap to some degree, since improved manufacturability usually results in

lower cost, the scope of design for product cost extends beyond only

manufacturing in its pursuit of cost savings, as indicated by the list of

typical product cost components in Table 25.5.

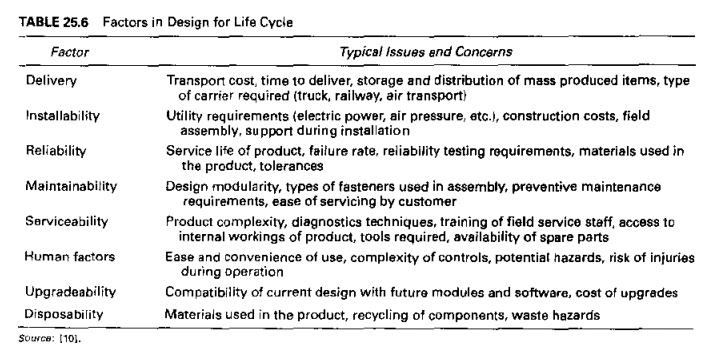

Design

for Life Cycle. To the customer, the price paid for the product may

be a

small

portion of its total cost when life cycle costs are considered. Design for life cycle refers to the product

after it has been manufactured and includes factors ranging from product

delivery to product disposal. Most of the significant life cycle factors are

listed in Table 25.6. Some customers (e.g., the federal government) include

consideration of these costs in their purchasing decisions. The producer of the

product is often obligated to offer service contracts that limit customer liability

for out-of-control maintenance and service costs. In these cases, accurate

estimates of these life cycle costs must be included in the total product cost

.

Related Topics