Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Process Planning and Concurrent Engineering

Advanced Manufacturing Planning

ADVANCED MANUFACTURING

PLANNING

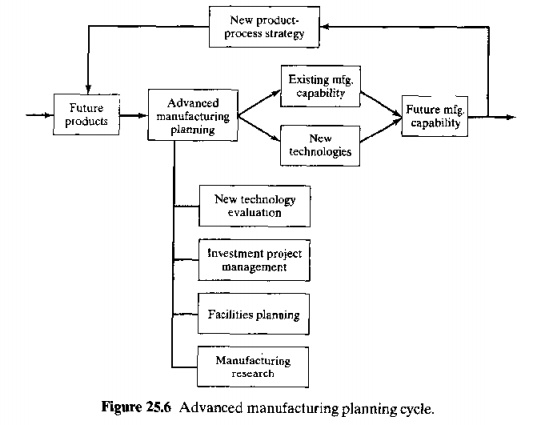

Advanced manufacturing

planning emphasizes planning for the future. It is a corporate level activity

that to distinct from process planning because it is concerned with products

being contemplated in the company's long-term plans (210year future), rather

than products currently being designed and released. Advanced manufacturing planning involves working with sates,

marketing, and design engineering to forecast the new products that will be

introduced and to determine what production resources will be needed to make

those future products. Future products may require manufacturing technologies

and facilities not currently available within the firm. In advanced

manufacturing planning, the current equipment and facilities are compared with

the processing needs created by future planned products to determine what new

facilities should be installed. The general planning cycle is portrayed in

Figure 25.6. Activities in advanced manufacturing planning include: (1) new

technology evaluation, (2) investment project management, (3) facilities

planning. And (4) manufacturing research

New

Technology Evaluation. Certainly one of the reasons why a company may consider installing

new technologies is because future product lines require processing methods not

currently used by the company. To introduce the new products. the company must

either implement new processing technologies in-house or purchase the

components made by the new technologies from vendors. For strategic reasons, it

may be in the company's interest to install a new technology internally and

develop staff expertise in that technology as a distinctive competitive

advantage for the company. These issues must be analyzed, and the processing

technology itself must be evaluated to assess its merits and demerits.

A good

example of the need for technology evaluation has occurred in the

microelectronics industry, whose history spans only the past several decades.

The technology of microelectronics has progressed very rapidly, driven by the

need to include ever-greater numbers of devices into smaller and smaller

packages. As each new generation has evolved, alternative technologies have

been developed both in the products themselves and the required processes to

fabricate them. It has been necessary for the companies in this industry. as

wel! as companies that use their products, to evaluate the alternative

technologies and decide which should be adopted

There an:

other reasons why a company may need to introduce new technologies: (1) quality improvement. (2) productivity

improvement, (3) cost reduction, (4) lead time reduction, and (5) modernization

and replacement of worm-out facilities with new equipment. A good example of

the introduction of a new technology is the CAD/CAM systems that were installed by

many companies during the t 980s. Initially, CAD/CAM was introduced to

modernize and increase productivity in the drafting function in product design.

As CADlCAM

technology itself evolved and its capabilities expanded to include three dimensional

geometric modeling, design engineers began developing their product designs on

these more powerful systems. Engineering analysis programs were written to perform

finite-element calculations for complex heat transfer and stress problems. The

usc of CAD had the effect of increasing design productivity, improving the

quality of the design, improving communications, and creating a data base for

manufacturing. In addition, CAM software was introduced to implement process

planning functions such as numerical control part programming (Section 6.5) and

CAPP, thus reducing transition time from design to production

Investment

Project Management. Investments in new technologies or new equipment

are generally made one project at a time. The duration of each project may be

several months to several years. The management of the project requires a

collaboration between the finance department that oversees the disbursements, manufacturing

engineering that provides technical expertise in the production technology, and

other functional areas that may be related to the project. For each project,

the following sequence of steps must usually be accomplished: (1) Proposal to

justify the investment is prepared.

(2)

Management approvals are granted for the investment. (3) Vendor quotations are

solicited. (4) Order is placed to the winning vendor. (5) Vendor progress in

building the equipment is monitored. (6) Any special tooling and supplies are

ordered. (7) The equipment is installed and debugged. (8) Training of

operators. (9) Responsibility for running the equipment is turned over to the

operating department.

Facilities

Planning. When new equipment is installed in an existing plant, an alteration of

the facility is required. Fluor space must be allocated to the equipment, other

equipment may need to be relocated or removed, utilities (power, heat, light,

air, etc.] must be connected, safety systems must be installed if needed, and various

other activities must be accomplished to complete the installation. In extreme

cases, an entire new plant may need to be designed to produce a new product line

or expand production of an existing line. The planning work required to

renovate an existing facility or design a new one is carried out by the plant

engineering department (or similar title) and is called facilities planning. In

the design or redesign of a production facility. manufacturing engineering and

plant engineering must work closely to achieve a successful installation.

Facilities planning is

concerned with the planning and design of the fixed assets (e.g land. buildings, and equipment) of an

organization. Facilities planning can be divided into two types of problems:

(1) facilities location and (2) facilities design. Facilities location deals with the problem of determining the optimum geographical location for a

new facility. Factors that must be considered in selecting the best location

include: location relative to customers and suppliers. Labor availability skills of labor pool, transportation, cost of living. quality of life. energy costs,

construction (;OSIS. and tax and other incentives that may be offered by the 10l:alor state government. The choices i:l facilities location include

international a~ well as national alternatives. Once the general location of

the facility has been decided (i.e.,state and region within the state). the

local site must be selected.

Facilities design consists

of the design of the plant, which includes plant layout, material handling.

building, and related issues. The plant

layout is the physical arrangement of equipment and space in the building.

Objectives in designing a plant layout include logical work flow. minimum material movement. convenience

of those using the facility. safety, expandability, and flexibility in case

rearrangement is necessary. Material

handling is concerned with the efficient. movement 01 work in the factory.

This is usually accomplished by means of equipment such as powered forklift

trucks. conveyors of various types. automatic guided vehicles. cranes, and

hoists (Chapter 10). Material

handling and plant layout arc closely related design issues. Building design deals with the

architectural and structural design of the plant and includes not only brick,

and mortar but also utilities and communications lines

Manufacturing Research

and Development. To develop the required manufacturing technologies, the

company may find it necessary to undertake a program of manufacturing research

and development (R&D). Some of this research is done internally, whereas in

other cases projects are contracted to university and commercial research

laboratories specializing in the associated technologies. Manufacturing

research can take various forms. including:

Development

of new processing technologies - This R&D activity involves the

development of new processes that have never been used before. Some of the

processing technologies developed for integrated circuits fabrication represent

this category Other recent examples include rapid prototyping techniques

(Section 24.1.2).

Adaptation

of existing processing technologies A manufacturing process may exist that has never been used on the type of

products made by the company yet it is perceived that there is a potential for

application. In this case, the company must engage in applied research to

customize the process to its needs.

Process

fine. tuning This involves research on processes used by the

company. The objectives of a given

study can be any of the following; (J) improve operating efficiency, (2)

improve product quality, (3) develop a process model, (41 learn how to better

control the process. (5) determine optimum operating conditions, and so forth.

Software

systems development - These are projects involving

development of customized manufacturing related software for the company.

Possible software development projects might include: cost estimating software,

parts classification and coding systems. CAPP, customized CAD/CAM application

software, production planning and control systems, work-in-process tracking

systems. and similar projects. Successful development of a good software

package may give the company a competitive advantage

Automation

systems development - These projects are similar to the

preceding except they deal with hardware or hardware/software combinations.

Studies related to

applications

of industrial robots (Chapter 7) in the company are examples of this kind of

research .

Operations

research and simulation Operations research

involves the development of

mathematical models to analyze operational problems. The techniques include

linear programming, inventory models, queuing theory, and stochastic processes.

In many problems, the mathematical models are sufficiently complex that they

cannot be solved in closed form. In these cases, discrete event simulation can

be used to study the operations. A number of commercial simulation packages are

available for this purpose.

Manufacturing

R&D is applied research. The objective is to develop or adapt a technology or technique

that will result in higher profits and a distinctive competitive advantage for

the company.

Related Topics