Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Process Planning and Concurrent Engineering

Computer Aided Process Planning

COMPUTER AIDED

PROCESS PLANNING

There is

much interest by manufacturing firms in automating the task of process planning

using computer-aided process planning (CAPP) systems. The shop trained people

who are familiar with the details of machining and other processes are

gradually retiring, and these people will be unavailable in the future to do

process planning. An alternative way of accomplishing this function is needed,

and CAPP systems are providing this alternative.

CAPP is

usually considered to be part of computer-aided manufacturing (CAM). However,

this lends to imply that CAM is a standalone system. In fact, a synergy results

when CAM is combined with computer-aided design to create a CAD/CAM system. In

such a system, CAPP becomes the direct connection between design and

manufacturing. The benefits derived from computer -automated process planning

include the following:

Process

rationalization and standardization. Automated process planning leads

to more logical and consistent

process plans than when process planning is done completely manually. Standard

plans tend to result in lower manufacturing costs and higher product quality.

Increased

productivity of process planners. The systematic approach and the availability

of standard process plans in the data files permit more work to be accomplished

by the process planners.

Reduced

lead time for process planning. Process planners working with a

CAPP system can provide route sheets in a shorter lead time compared to manual

preparation.

Improved

legibility. Computer-prepared route sheets are neater and

easier to read than manually prepared

route sheets,

Incorporation o other application programs The CAPP

program can be interfaced With other

application programs, such as cost estimating and work standards.

Computer-aided

process planning systems are designed around two approaches. These approaches

are called: (1) retrieval CAPP systems and (2) generative CAPP systems. Some

CAPP systems combine the two approaches in what is known as semi-generative

CAPP.

Retrieval CAPP Systems

A retrieval CAPP system, also called a variant CAPP system, is based on the

principles of group technology (GT) and parts classification and coding

(Chapter 15), In this type of CAPP, a standard process plan (route sheet) is

stored in computer files for each part code number. The standard route sheets

are based on current part routings in use in the factory or on an ideal process

plan that has been prepared for each family. It should be noted that the

development of the data base of these process plans requires substantial

effort.

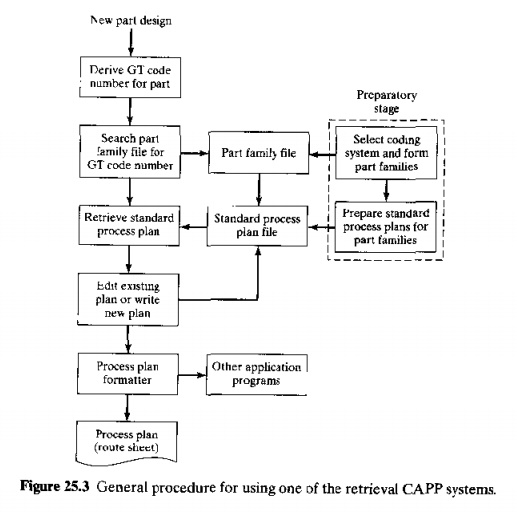

A

retrieval CAPP system operates as illustrated in Figure 25.3. Before the system

can be used for process planning, a significant amount of information must be

compiled and entered into the CAPP data files. This is what Chang et al., refer

to as the "preparatory phase:' It consists of the following steps: (1)

selecting an appropriate classification and coding scheme for the company, (2)

forming part families for the parts produced hy the company; and (3) preparing

standard process plans for the part families. It should be mentioned that steps

(2) and (3) continue as new parts are designed and added to the company's design

data base.

After the

preparatory phase has been completed, the system is ready for use, For a new

component for which the process plan is to be determined. the first step is to

derive the GT code number for the part. With this code number, a search is made

of the part family, file to determine if a standard route

sheet exists for/he given part code. If the file contains a process plan for

the part it is retrieved (hence. the word "retrieval" for this CAPP

system) and displayed for the user. The standard process plan is examined to

determine whether any modifications are necessary. It might be that although

the new part has the same code number. there are minor differences in the

processes required to make it. The user edits the standard plan accordingly.

This capacity to alter an existing process plan is what gives the retrieval

system its alternative name: variant CAPP system.

If the

file does not contain a standard process plan for the given code number, the

user may search the computer file for a similar or related code number for

which a standard route sheer does exist. Either by editing an existing process

plan, or by starting from scratch, the user prepares the route sheet for the

new part. This route sheet becomes the standard process plan for the new part

code number

The

process planning session concludes with the process plan formatter, which

prints alit the route sheet in the proper format. The formatter may call other

application programs into use: for example, to determine machining conditions

for the various machine tool operations in the sequence. to calculate standard

times (or the operations (e.g., for direct labor incentives). or to compute

cost estimates for the operations.

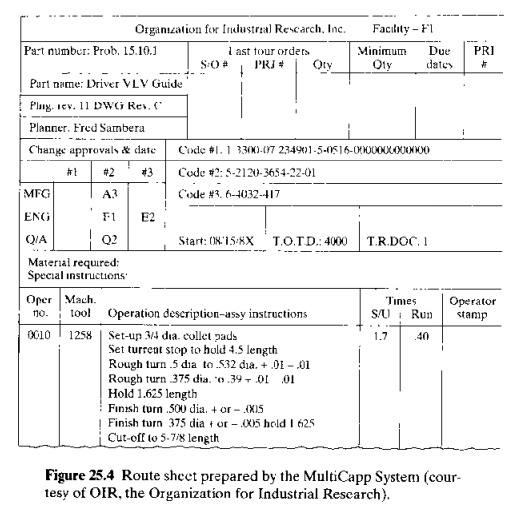

One of

the commercially available retrieval CAPP systems is MultiCapp, from OIR the

Organization for Industrial Research. It is an online computer system that

permits the user to create new plans. or retrieve and edit existing process

plans, as we have explained above. An example at a route sheet representing the

output from the MultiCapp system is shown in Figure 25.4.

Generative

CAPP Systems

Generative

CAPP systems represent an alternative approach to automated process planning.

Instead of retrieving and editing an existing plan contained in a computer data

base, a generative system creates the process plan based on logical procedures

similar to the procedures a human planner would use. In a fully generative CAPP

system, the process sequence is planned without human assistance and without a

set of predefined standard plans.

The

problem of designing a generative CAPP system is usually considered part of the

field of expert systems, a branch of artificial intelligence. An expert system is a computer program that

is capable of solving complex problems that normally require a human with years

of education and experience. Process planning fits within the scope of this

definition.

There are

several ingredients required in a fully generative process planning system.

First. the technical knowledge of manufacturing and the logic used by

successful process planners must be captured and coded into a computer program.

In an expert system applied to process planning, the knowledge and logic of the

human process planners is incorporated into a so called "knowledge

base."The generative CAPP system then uses that knowledge base to solve

process planning problems {i.e., create route sheets).

The

second ingredient in generative process planning is a computer-compatible description

of the part to be produced. This description contains all of the pertinent data

and information needed to plan the

process sequence, Two possible ways of providing this description are: (l) the

geometric model of the part that is developed on a CAD system dur10g product

design and (2) a GT code number of the part that defines the part features in significant

detail.

Figure

25.4 Route sheet prepared by the MultiCapp System (courtesy of OIR, the

Organization for Industrial Research).

The third

ingredient in a generative CAPP system is the capability to apply the process

knowledge and planning logic contained in the knowledge base to a given part

description. In other words, the CAPP system uses its knowledge base to solve a

specific problem-planning the process for a new part. This problem-solving

procedure is referred to as the "inference engine’ in the terminology of

expert systems. By using its knowledge base and inference engine, the CAPP

system synthesizes a new process plan from scratch for each new part it is

presented.

Related Topics