Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Control Systems

Computer Process Control

COMPUTER PROCESS CONTROL

Computer Process Control

• Control Requirements

• Capabilities of Computer Control

• levels of Industrial Process Control

The use

of digital computers to control industrial processes had its origins in the

continuous process industries in the late 1950s (Historical Note 4.1). Prior to

then, analog controllers were used to implement continuous control, and relay

systems were used to implement discrete control. At that time, computer

technology was in its infancy, and the only computers available for process

control were large, expensive mainframes. Compared with today's technology, the

digital computers of the 195Ch;were slow, unreliable, and not well suited to

process control applications. The computers that were installed sometimes cost

more than the processes they controlled. Around 1960, digital computers started

replacing analog controllers in continuous process control applications; and

around 1970, programmable logic controllers started replacing relay hanks in

discrete control applications. Advances III computer

technology Since the 1960s and 1970.~have resulted in the de:elopm~nl of the

microprocessor. Today, virtually all industrial processes, certainly new

installations, are controlled by digital computers based on microprocessor

technology. Microprocessorbased controllers are discussed in Section 4.4.6.

The available computers In the late I950s were not

reliable, and most of the subsequent process control installations operated by

euher printing out instructions for the operator or by making adi\lstments in

the set points (If analog

controllers, thereby reducing the risk of process downtime due to compute:

problems. The latter mode of operation was called set point conlrol. By March 1%1, a total of 37 computer process

control systems had been installed. Much experience

was gamed from these early installations. The interrupt feature (Section 4.3.2). by which the computer suspends

current program execution to quickly respond to a process need. was developed

during this period.

The first direct

digitai control (DOC) system

(Section 4.4.2), in which certain analog de" vices are replaced by the

computer, was installed by Imperial Chemical Industries in England in 1%2. In

this onplementauon.zza process variables were measured, and 129actuators

(valves) wcr~ controlledImprovements in DOC technology were made, and

additional systems were installed during thc 1%0s. Advantages 01 DOC noted

during this time included: (1) cost savings from elimination of an~l"g

instrumentationfor large systems. (2) simplified operator dis_ play pencts, and

,:3) flexibility through reprogramming capability.

Computer

technology was advancing. leading to the development of the minicomputer

in thelate 1960s.Process cnntrol applications were

easier to justify using theses maller, lessexpensive computers. Development of

the microcomputer in the early 1970s

continued this trend. Lower cost process conlrol hardware and Interface

equipment (such as analogtodlgltal converters) were becoming available due to

the larger markets made possible by lowcost computer controllers.

Most of the developments in computer process control up to this time were biased toward theprocessinduslriesrath",rthandiscretc part and product manufacturing. Just as analog devices had been used to automate process industry operations, relay banks were widely used to satisfy the ciscrcte process control (ON/OFF) requirements in manufacturing automation.

Let us consider the requirements

placed on the computer in industrial control applications. We then examine the

capabilities that have been incorporated into the control computer to address

these requirements. and finally we observe the hierarchical structure of the

functions performed by the control computer.

Control

Requirements

Whether

the application involves continuous control, discrete control. or both, there

are certain basic requirements that tend to he common to nearly all process

control applications. By and large, they are concerned with the need to

communicate and interact with the process on arealtime basis.A reallime controller is able to respond

to the process within a short enough time period that process performance is

not degraded. Factors that determine whether a computer controller can operate

in realtime include: (1) the speed of the controller's central processing unit

(CPU) and its interfaces, (2) the controller's operating system, (3) the design

of the application software, and (4) the number of different input/out. put

events to which the controlier is designed to respond. Realtime control usually

requires the controller to be capable of multitasking,

which means coping with multiple tasks concurrently without the tasks

interfering with one another.

There are two basic requirements that must be

managed by the controller to achieve realtimeeontrol:

Processinitiated interrupts. The

controller must be able to respond to incoming signals from the process.

Depending on the relative importance of the signals, the computer may need to

interrupt execution of a current program to service a higher priority need of

the process. A processinitiated interrupt is often triggered by abnormal

operating conditions, indicating that some corrective action must be taken

promptly.

Timerinitialed actions. The controller must be capable of executing certain actions at specified points in time. Timerinitiated actions can be generated at regular time intervals,ranging from very low values (e.g., 100 j.ts) to several minutes. or they can be generated at distinct points in time. Typical timerinitiated actions in process control include: (1) scanning sensor values from the process at regular sampling intervals, (2) turning on and off switches, motors, and other binary devices associated with the process at discrete points in time during the work cycle, (3) displaying performance data on the operator's console at regular times during a production run, and (4) recomputing optimal process parameter values at specified times.

These two requirements correspond to the two types

of changes mentioned previously in the context of discrete control systems: (l)

eventdriven changes and (2) timedriven changes.

In addition to these basic requirements. the

control computer must also deal with other types of interruptions and events.

These include:

Computer

commands to process. In addition to incoming signals from the process, the control computer must be able to

send control signals to the process to accomor readjust a 5ct point in 5iyrtem and programmitiated IT('nts. These are events related to the

computer systerri itself 'lhcv arc similar to the kinds of corr.puter

operations associated with business and eng:ineering applications of computers.

A systeminitiated event involves

communications among ~ompl!ten and peripher<ll devices linked together in a

network. In these multiple computer networks, feedback signals, control

commands, and other data must be transferred back and forth among the computers

in the overall control of the process. A programinitiated

{'vent is when some nonprocessrelated action is called for in the program.such

as the pr.ntiug or display of reports on a printer or monitor. In process

coutrut, vvstern and programinitiated events generally occupya low level of

priority compared with process interrupts, commands to the process. and

timerinitiated events

Capabilities of Computer Control

The above requirements can he satisfied by

providing the controller with certain capabttitics that allow it 10 interact on

a realtime basis with the process and the operator, The capabilities are: (1)

polling, (2) interlocks. (3) interrupt system, and (4) exception handling.

Polling (Data Sampling). In

computer process control,polllNg refers 10

the periodic ~ampling of data that indicates the status of the process. When

the data consist of a continuous analog ~ignal. sampling means that the continuous

slgnalrs substituted with a series of numerical values that represent the

continuous signal at discrete moments in time. The same kind of substitution

holds for discrete data. except that the number of possible numerical values

the data can take on i~more

limitedccertainly the case with binary data We discuss the techniques by which

continuous and discrete datil are entered into and transmitted from the

computer in Chapter 5. Other names used for polling include sampling and scanning

In some polling procedure simply requests whether

any changes have the last polling cycle and then collects only the new data

from shorten the cycle time required for polling. Issues related to

Polling order. The polling order is the sequence

in which the different data collection points

of the process are sampled.

Polling formal. This

refers to the manner in which the sampling procedure is designed. The

alternatives include: (a) entering all new data from all sensors and other

devices ~very polling cycle; (b) updating the control system only with data

that have changed since the last polling cycle; or (c) using highlevel and towlevdscanntng.ot conditional scanning, in which only

certain key data are normally collected each polling cycle (highlevel

scanning), but if the data indicates some irregularity in the process. a

lowlevel scan i~undertaken

to collect morecomplete data to ascertain the source of the irregularity.

These issues become increasingly critical with very

dynamic processes in which changes in process S(;JIII, occur rapidly

Interlocks. An inrerlock is a safeguard mechanism for

coordinating the activities of two or more devices and

preventing vue device from interfering with the otherts). In process control.

interlocks provide a means by which the controller is able to sequence the

activities in a work cell, ensuring that the actions of one piece of equipment

arc completed before the next piece of equipment begins its activity.

Interlocks work by regulating the flow of control signals back and forth

between the controller and the external devices.

There are two types of interlocks, input interlocks

and output interlocks, where input and output are defined relative to the

controller. An input interlock is a

signal that originates from an external device (e.g., a limit switch, sensor,

or production machine) and is sent to the controller. Input interlocks can be

used for either of the following functions:

To proceed with the execution of the work

cycle program. For example, the production machine communicates a signal to the

controller that it has completed its processing of the part. This signal

constitutes an input interlock indicating that the controller can now proceed

to the next step in the work cycle, which is to unload the part.

To interrupt the execution of the work

cycle program. For example, while unloading the part from the machine, the

robot accidentally drops the part. The sensor in its gripper transmits an

interlock signal to the controller indicating that the regular work cycle sequence

should be interrupted until corrective action is taken.

An output

interlock is a signal sent from the controller to some external device. It

is used to control the activities of each external device and to coordinate its

operation with that of the other equipment in the cell. For example, an output

interlock can be used to send a control signal to a production machine to begin

its automatic cycle after the workpart has been loaded into it.

lnterrupt System. Closely

related to interlocks is the interrupt system. As suggested by our discussion

of input interlocks, there are occasions when it becomes necessary for the

process or operator to interrupt the regular controller operation to deal with

morepressing matters. All computer systems are capable of being interrupted; if

nothing else, by turning off the power. A moresophisticated interrupt system is

required for process control applications. An interrupt system is a computer control feature that permits the

execution of the current program to be suspended to execute another program or

subroutine in response to an incoming signal indicating a higher priority

event. Upon receipt of an interrupt signal, the computer system transfers to a

predetermined subroutine designed to deal with the specific interrupt. The

status of the current program is remembered so that its execution can be

resumed when servicing of the interrupt has been completed.

Interrupt conditions can be classified as internal

or externaL Internal interrupts are

generated hy the computer system itself. These include timerinitiated events,

such as polling

of data from sensors connected to the process, or

sending commands to the process at specific points 10 clock time. System and

programinitiated interrupts are also classified as

important programs higher priority) Be executed

before Jessimportant programs (ones with lower prioruiesj.Thc system designer

must decide what level of priority should be attached to each control function.

A higher priority function can interrupt a lower primity function. A function

at a given priority level cannot interrupt a function at the same priority

level. The number of priority levels and the relative importance of the

functiom depend on the l<:'[uir<:I1n;nl>of the individual process

control situation. For example, emergency shutdown of a process because of

safety hazards would occupy a very high priority level, even though it may be

an operator. initiated interrupt. Most operator in" puts would have low

priorities.

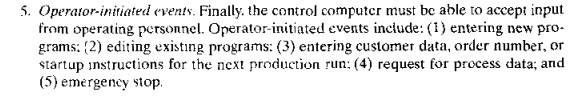

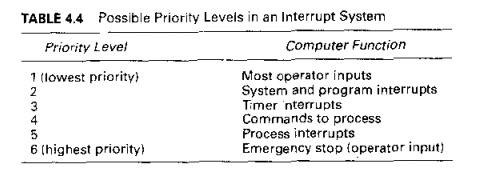

One possible organization of priority rankings for

process control functions is shown IIITable 4.4. Of course, the priority system

may have more or less than the number of levcis shown here. depending on the

control situation. For example, some process interrupts may be more important

than others. and some system interrupts may take precedence over certain

process interrupts, thus requiring more than the six levels indicated in our

table

To respond 10 the various levels of priority

defined for a given control application, an interrupt system can have one or

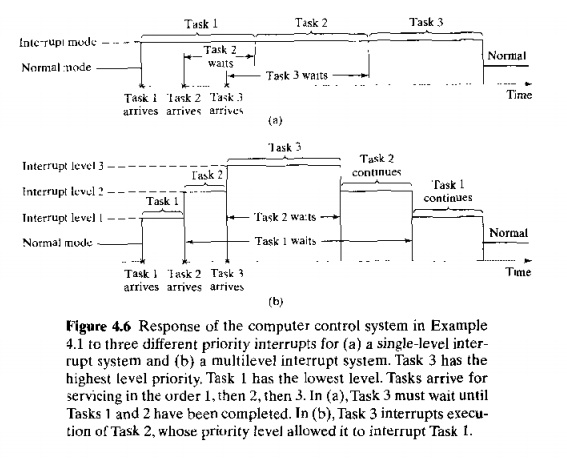

more interrupt levels. A singlelevel

interrupt system has only two modes of operation: normal mode and

interrupt mode. The normal mode can be interrupted, but the interrupt mode

cannot. This means that overlapping interrupts arc serviced on a firstcome.

firstserved basis, which cOllld have potentially hazardous consequences it an

important process interrupt was forced to wait its tum while a series of

lessimportant operator and system interrupts were serviced. A multilevel interrupt system has a normal

operating mode plus more than one interrupt level. The normal mode can be

interrupted hy any interrupt level. hut the interrupt levels have relative priorities

that determine which functions can interrupt others. EXample 4.1 illustrates

the difference between the singlelevel and multilevel interrupt systems.

EXAMPLE 4.1 SingleLevel Versus Multilevel Interrupt

Systems

Three

Interrupts representing tasks of three different priority levels arrive for

service in the reverse order of (heir respective priorities. Task 1with the

lowest priority, arrives first. Shortly later.higher priority Task 2 arrives.

And shortly later,

highest pnority Task 3 arrives. How would the

computer control system respond under (a) a suvglcle ce! interrupt system and

(b) a rnurt'ilevcl interrupt system?

Exception

Handling. In process control, an exception is

an even! that is outside the norma!

or desired operation of the process or control system. Dealing with the

exception is an essential function in industrial process control and generally

occupies a major portion of the control algorithm. The need for exception

handling may be indicated through the normal polling procedure or by the

interrupt system. Examples of events that may invoke exception handling

routines include:

product quality

problem

process variables

operating outside their

normal ranges

shortage of raw materials or supplies

necessary to sustain the process

hazardous conditions

such as a fire

controller malfunction

In effect, exception handling is a form of error

detection and recovery, discussed in the context of advanced automation

capabilities (Section 3.2.3).

Levels of Industrial Process Control

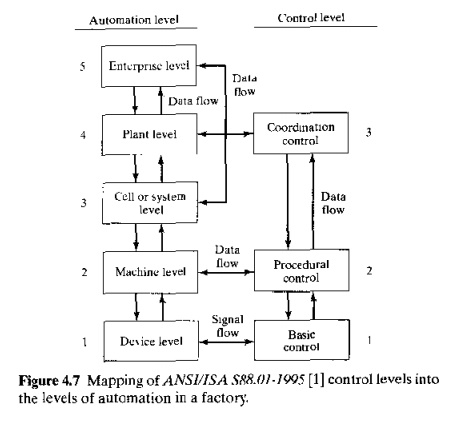

In general. industrial control systems possess a

hierarchical structure consisting of multiple levels of functions, similar to

our levels of automation described in the previous chap. ter [Table 4.2). ANSIIISAS88.011995J [1]

divides process control functions into three

levels:

(1) basic control, (2) procedural control, and (3) coordination contro1.These

control levels map into our automation hierarchy as shown in Figure 4.7, We now

describe the three control levels, perhaps adapting the standard to fit our own

models of continuous and discrete control (the reader is referred to the

original standard [1], available from the Instrument Society of America)

Basic

Control. This is the lowest level of control defined in the standard,

corresponding to the device level in our automation hierarchy. In the process

industries, this level is concerned with feedback control in the basic control

loops. In the discrete manufacturing industries, basic control is concerned

with directing the servomotors and other actuators of the production machines.

Basic control includes functions such as feedback control. polling,

interlocking, interrupts. and certain exception handling actions. Basic control

functions may be activated.deactivated, or modified by either of the higher

control levcis (procedural or coordination control) or by operator commands.

Procedural Control. This

intermediate level of control maps into regulatory control of unit operations

in the process industries and into the machine level in discrete manufacturing

automation (Table 4.2). In continuous control, procedural control functions

include using data collected during polling to compute some process parameter

value, changing serpoints and other process parameters in basic control, and

changing controller gain constants, In discrete control, the functions are

concerned with executing the work cycle program, that is.directing the machine

to perform actions in an ordered sequence to accomplish sornc productive task. PI ocedural control may also

involve executing error detection and recovery procedures and making decisions

regarding safety hazards that occur during the process,

Coordination Control. This is

the highest level in the control hierarchy in the A'JSI/ISA standard. It

corresponds to the supervisor} level in the process industries and the cell or

system level in discrete manufacturing. It is also likely to involve the plant

and possibly the enterprise levels of automation. Coordination control

initiates, directs, or alters the execution of programs at the procedural

control level. Its actions and outcomes change over rime. as in procedural

control. but its control algorithms are not stnleturoo for a specific processoriented

task. It IS more reactive and adaptive. Functions of coordination control at

the celllevel include.coordinating the actions of groups of equipment or

machines.coordinating material handling activities between machines in a cell

or system, allocating production orders to machines in the cell, and selecting

among alternative work cycle programs.

At the plant and enterprise levels. coordination

control is concerned with manufacturing support functions, including production

planning and scheduling; coordinating common resources. such as equipment used

in more than one production cell; and supervising availability, utilization.

and capacity of equipment. These control functions are accomplished through the

company's integrated computer and information system.

Related Topics