Chapter: Pharmaceutical Biotechnology: Fundamentals and Applications : Regulatory Issues and Drug Product Approval for Biopharmaceuticals

Background Regulatory Issues for Biopharmaceuticals

BACKGROUND

The aim of this chapter is to provide a comprehensive view on the

regulatory issues for the approval of a

biosimilar product. In order to have a better understanding of the regulatory

process involved, it is essential to appreciate the basic difference between

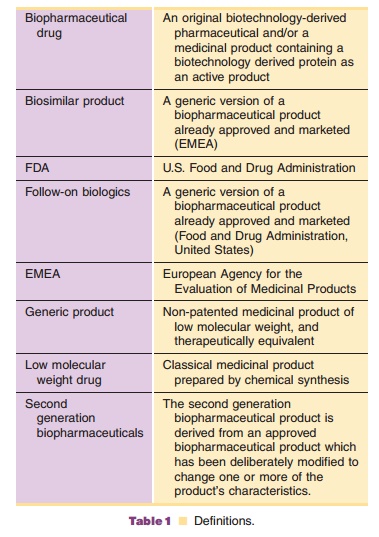

small drug molecules and macromolecules and their approval process. Table 1 provides

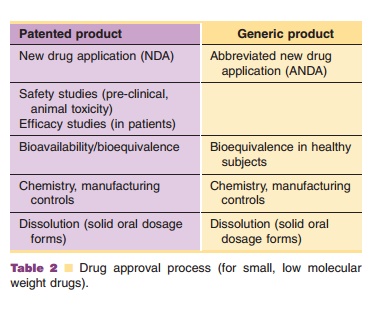

the definitions of different classes of medicinal drug products. Table 2

provides the steps involved in the drug approval process of small molecules.

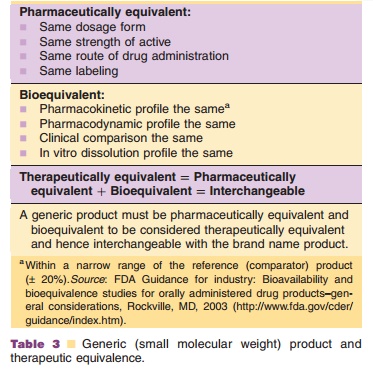

For the approval of a (small molecule) generic product, it must be

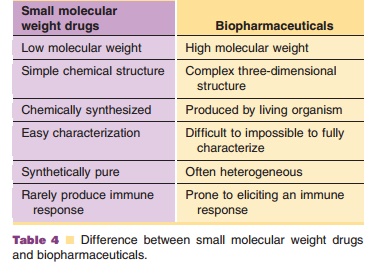

pharma-ceutically equivalent and bioequivalent (Table 3). Biopharmaceuticals

have a number of characteristics (Table 4) that set them aside from small

molecule drugs (Crommelin et al., 2003). The efficacy and safety of biotech

products depend on their complicated, rather labile shape built up of

secondary, tertiary and sometimes quaternary structures.

The mission of a regulatory authority is to “Assure that safe, effective

and high quality drugs are marketed in the country and are available to the

people”. Safety of an innovator’s drug product, be it a small molecule or

biopharmaceutical, is established through preclinical studies in animals and

controlled clinical studies in humans. Efficacy is established through clinical

studies in patients. A complete set of information on Chemistry, Manufacturing

and Controls (CMC-section) is needed in the dossier submitted for approval to

ensure that the drug substance and the drug product are, pure, potent and of

high quality. The CMC section should include full analytical characterization,

a description of the manufacturing process and test methods, and stability

data. In addition to the establishment of safety and efficacy of the drug

product, the approval process requires manufacturing of the drug product under

controlled current good manufacturing practice (cGMP) conditions. The cGMP

requirement ensures identity, potency, purity, quality and safety of the final

product. These features include process robustness and reproducibility,

validation, controls and testing. Batch release criteria are established to

assure complex manufacturing process of

biopharmaceuti-cals involving living organisms. The production process should

be controlled in every minor detail. Moreover, a long list of analytical

techniques is presented to characterize biopharma-ceuticals, but in many

instances full characterization is not possible with our current toolbox of

analytical techniques.

A generic product (small molecule) contains the same active ingredient

with inactive (most of the time) excipients as the reference product. As

explained above, this is not always possible in biopharmaceu-tical protein

products and therefore, these are not referred to as biogenerics. This biopharmaceutical

product contains the active ingredient which is similar (but not necessarily

equal) in characteristics to the reference product. For this reason, the

generic biopharmaceutical products are referred to as fol-low-on proteins or

follow-on biologics or biosimilar products. A biosimilar product has a

pharmacological and therapeutic activity that is similar to the reference

(comparator) product, but may differ in its pharma-ceutical equivalence

(characteristics). Biosimilar products are not generic products since it could

be expected that there may be subtle differences between the biosimilar and

reference product from the innovator and are not interchangeable with brand

name products.

Related Topics