Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Lean Production and Agile Manufacturing

Agile Manufacturing

AGILE

MANUFACTURING

As an observed "system of doing business:' agile manufacturing emerged after lean production (Historical Note 27.2) yet shares many aspects, as we shall see when we compare the two. in Section 27.3: Agile manufacturing can he defined as (1) an enterprise level manufacturing strategy of introducing new products into rapidly changing markets and (2) anorganizational ability to thrive in a competitive environment characterized by continuous and sometimes unforeseen change.

The 1991

study identified four principles of agility" Manufacturing companies that

are agile competitors tend to exhibit these principles or characteristics. The

four principles are:

Organize to Master Change " An agile

company is organized in a way that allows

it to thrive on change and uncertainty'? In a company that is agile, the

human and physical resources can be rapidly reconfigured to adapt to changing

environment and market opportunities.

Leverage the Impact of People and

Information - In an agile company, knowledge is valued, innovation is rewarded, authority is distributed to the

appropriate level of the organization. Management provides the resources that

personnel need. The organization is entrepreneurial in spirit. There is a

"climate of mutual responsibility for joint success'"

Cooperate

to Enhance Competitiveness - "Cooperation internally and

with other companies is an agile

competitor's operational strategy of first choice."? The objective is to

bring products 10 market as rapidly as possible. The required resources and

competencies (Ire found and melt wherever they exist. This may involve partnering

with other companies, possibly even competing companies. to form virtual enterprises {Section 27.2.3)

Enrich

the Customer" - An agile company is perceived by its customers as

enriching them in a significant way.

not only itsclf.'" The products of an agile company are perceived as

solutions to customers' problems. Pricing of the product can be based on he

value of the solution to the customer rather than on manufacturing cost

A~ our

definition and the list of four agility principles indicate, agile

manufacturing involves more than Just manufacturing. It involves the firm's

organizational structure, it involves the way the firm treats it people. it

involves partnerships with other organizations, and it involves relationships

with customers. Instead of "agile manufacturing," it might be more

appropriate to just call this new system of doing business "agility:"

Market

Forces and Agility

A number

of market forces Can be identified that are driving the evolution of agility

and agile manufacturing in business. These forces include:

Intensifying

competition Signs of intensifying competition include (I) global

competition, (2) decreasing cost of information, (3) growth in communication

technologies.(4'! pressure to reduce time to market, (5) shorter product lives.

and (6) increasing pressures on costs and profits

Fragmentation

of mass markets Mass production was justified by the existence of very large markets for mass produced

products. The signs of the trend toward fragmented markets include: (1)

emergence of niche markets, for example, different sneakers for different

sports and non sports applications; (2) high rate of model changes;

declining barriers to market entry from global

competition; and (4) shrinking windows of market opportunity. Producers must

develop new product styles in shorter development periods.

Cooperative

business relationships There is mare cooperation occurring

among corporations in the United

States. The cooperation takes many forms. including'

increasing inter enterprise cooperation, (2)

increased outsourcing, (3) global sourcing. (4) improved labor management

relationships. and (5) the formation of virtual

enterprises among

companies. One might view

the increased rate of corporate mergers that are occurring at time of writing

as an extension of these cooperative relationships.

Changing customer expectations Market

demands

are changing. Customers are becoming more sophisticated and individualistic in

their purchases. Rapid delivery of the

product. support throughout the product life. and high quality are attributes

expected by the customer of the product and of the company that manufactured

the product. Quality is no longer the basis of competition that it was in the

1970s and 19S0s.Today·~products me likely to have an increased information

content.

Increasing

societal pressures Modern companies are expected to be responsive tel social issues, including workforce

training and education, legal pressures, environmental impact issues. gender

issues, and civil rights issues.

Modern firrms

are dealing with these market forces by becoming agile. Agility is a strategy

for profiting from rapidly changing and continually fragmenting global markets

for customized products and services. Becoming agile is certainly not the only

objective of the firm. There are important other objectives, such as making a

profit and surviving into the future. However. becoming more agile is entirely

compatible with these other objectives. Indeed, becoming agile represents a

working strategy for company survival and future profitability.

How does

a company become more agile? Two important approaches are: (1) to reo organize

the company's production systems to make them more agile and (2) to manage

relationships differently and value the knowledge that exists in the organization.

Let us examine each of these approaches in a company's operations as it seeks

to become an agile manufacturing firm.

Reorganizing

the Production System for Agility

Companies

seeking to be agile must organize their production operations differently than

the traditional organization. Let us discuss the changes in three basic areas:

(1) product design. (2) marketing, and (3) production operations.

Product

Design. Reorganizing production for agility includes issues related to product

design. As we have noted previously, decisions made in product design determine

approximately 70'1(,of the manufacturing cost of a product. For a company to be

more agile, the design engineering department must develop products that can be

characterized as follows'

Customizable,

Products

can be customized for individual niche markets. In some cases, the product must be custornizable for individual customers.

Upgradeable.

It should

be possible for customers who purchased the base model to subsequently buy additional options to upgrade the product.

Reconfigurable.

Through

modest changes in design, the product can be altered to provide it with unique features. A new model can be developed from

the previous model without drastic and time consuming redesign effort.

Design

modularity. The product should be designed so that it consists

of several modules (e.g ..

subassemblies) that can he readily assembled to create the finished item. In

this way. if a module needs to be redesigned, the entire product does not

require redesign. The other modules can remain the same

Frequent model changes within

stable market families. Even for products that succeed in the marketplace. the company should nevertheless introduce new

versions of the product to remain competitive.

In addition.

the company must achieve rapid. Cost effective development of new products, and

it must have a life cycle design philosophy (the life cycle running from

initial concept through production. distribution, purchase. disposal. and

recovery).

Marketing.

A

company's design and marketing objectives must be closely linked The best

efforts of design may be lost if the marketing plan is flawed. Being an agile

marketing company suggests the following objectives. several of which arc

related directly to the preceding product design attributes

• Aggressive and proactive

product marketing. The sales and marketing functions of the firm should make change happen in

the marketplace. The company should bc the change agent that introduces the new

models and products

• Cannibalize successful

products. The company should introduce new models to replace and obsolete its most

successful current models.

• Frequent new product

introductions. The company should maintain a high rate of new product introductions.

• Life cycle product support. The

company must provide support for the product

throughout its life cycle

• Pricing by 'customer value. The price

of the product should be established according to its value to the customer rather than according to its own

cost.

• Effective niche market

competitor. Many companies have become successful by competing

effectively in niche markets. Using the same basic product platform, the

product has been reconfigured to provide offerings for different markets. The

sneaker industry is a good example here

Production Operations. A

substantial impact on the agility of the production system can be achieved by

reorganizing factory operations and the procedure, and systems that support

these operations. Objectives in production operations and procedures that are

consistent with an agility strategy are the following:

Be a cost

effective, low volume producer. This is accomplished using

flexible production systems and low setup times.

Be able

to produce to customer order. Producing to customer order

reduces inventories of unsold finished goods

Master

mass customization, The agile company is capable of economically

producing a unique product for an individual customer

Use reconfigurable and reusable

processes, tooling, and resources . Examples include computer numerical control machine

tools, parametric part programming, robots that arc reprogrammed for different

jobs, programmable logic controllers, mixed model

production

lines, and modular fixtures (fixtures designed with a group technology

approach, which typically possess a common base assembly to which are attached

components that accommodate the different sizes or styles of work units).

Bring

customers closer to the production process. Provide systems that enable customers

to specify or even design their own unique products. As an example, it has

become every common in the perxunal

computer market for customers to be able to order exactly the PC configuration

(monitor size, hard drive, and other options) and software that they want.

Integrate

business procedures with production. The production system should

include sales. marketing, order entry, accounts receivable, and other business

functions These functions are included in a computer integrated production

planning and control system based on manufacturing resource planning (MRP II,

Section 26.6)

Treat

production as a system that extends from suppliers through to customers. The company's own factory is a component in

a larger production system that includes suppliers that deliver raw materials

and parts to the factory. It also includes the suppliers' suppliers.

To

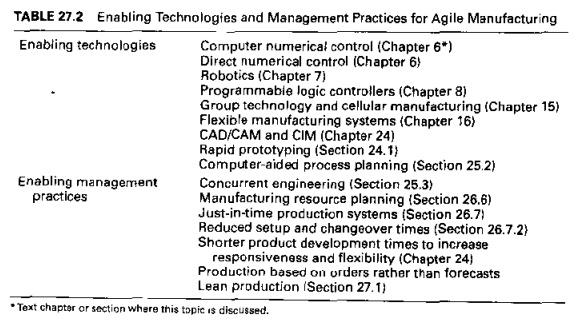

summarize, some of the important enabling technologies and management practices

to reorganize the production function for agile manufacturing are listed in Tatble27.2.

Managing Relationships for Agility

Cooperation

should be the business strategy of first choice (third principle of agility).

The general policies and practices that promote cooperation in relationships

and, in general, promote agility in an organization include the following:

o

management philosophy that promotes motivation and

support among employees

o

.trustbased relationships

o

empowered

workforce

o

shared

responsibility for success or failure

o

pervasive entrepreneurial spirit

TABLE 27.2 Enabling Technologies and

Management Practices for Agile Manufacturing

There are two different types of relationships that

should be distinguished in the context

agility; (1) internal relationships and (2) relationships between the company

and other organizations.

Internal Relationships. Internal

relationships arc those that exist within the firm. between coworkers and between supervisors and subordinates.

Relationships inside the firm must be managed to promote agility. Some of the

important objectives include

(1) make

the work organization adaptive. (2) provide cross functional training, (3)

encourage rapid partnership formation. and (4) provide effective electronic

communications capability

External relationships. External

relationships are those that exist between the company and external suppliers. customers, and partners, It is

desirable to form and cultivate external relationships for the following

reasons: (1) to establish interactive. proactive

relationships

with customers; (2) to provide rapid identification and certification of

suppliers: (3) to install effective electronic communications and commerce

capability and

(4) to

encourage rapid partnership formation for

mutual commercial advantage,

The

fourth reason raises the issue of the virtual enterprise. A virtual enterprise (the terms virtual organization and virtual corporation are also used) is

defined as a temporary partnership of independent resources (personnel, assets.

and other resources) intended to exploit a temporary market opportunity. Once

the market opportunity is passed and the objective is achieved. the

organization is dissolved. In such a partnership, resources are shared among

the partners. and benefits (profits) are also shared. Virtual enterprises arc

sometimes created by

competing firms.

The

formation of a virtual enterprise bas the following potential benefits: (1) It

may provide access to resources and technologies not available in house, (2) it

may provide access to new markets and distribution channels. (3) it may reduce

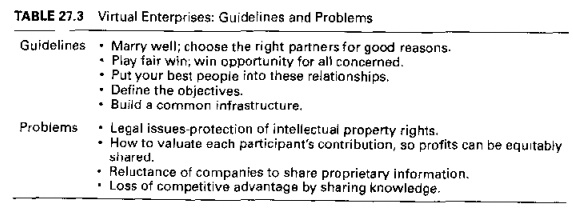

product development time, and (4) it accelerates technology transfer. Some of

the guidelines and potential problems associated With virtual enterprise are

listed in Table 27.3.

Valuing

Knowledge. We must begin discussion of this topic by stating a

fundamental premise. It is that the people in an organization, their skills and

knowledge and their

TABLE 27.3 Virtual Enterprises: Guidelines and Problems

Guidelines •Marry well; choose the right partners for good

reasons.

• Play

fair win; win opportunity for all concerned •Put your best people into these relationships,

•Define the objectives.

•Build a

common infrastructure.

Problems •legal

issues protection of intellectual property rights.

How to

valuate each participant's contribution, so profits can be equitably snared.

Reluctance of companies

to share proprietary information.

•Loss of

competitive advantage by sharing knowledge

ability

to use information effectively and innovatively, are distinguishing

characteristics of an agile competitor. To whatever extent this premise applies

to a given organization. the skill and knowledge base must be encouraged,

developed. and exploited for the good of the organization. Some of the

important objectives include: (1) open communication and information access, (2) openness to learning is pervasive

in the organization, (3) learning and knowledge arc basic attributes of an

organization's ability to adapt to change, (4) the organization provides and

encourages continuous education and training for all employees, and (5) there

is effective management of competency inventory, meaning that the organization

knows and capitalizes on the skills and knowledge of its employees.

Agility Versus Mass Production

Like lean

production, agility is often compared with mass production. In this comparison

we must interpret mass production to include all of the requisites that made it

successful, such as the availability of mass markets and the ability to

forecast demand for a given product in such mass markets. Our comparison is

summarized in Table 27.4. Let us elaborate on the items listed in the table.

In mass

production, companies produce large quantities of standardized products. The

purest form of mass production provides huge volumes of identical products.

Over the years, the technology of mass production has been refined to allow for

minor variations in the product (we call it "mixed model

production"). In agile manufacturing, the products are customized. The

term used to denote this form of production is mass customization, which means large quantities of products having

unique individual features that have been

specified by and/or customized for their respective customers. Referring to our

PO model of production in Chapter 2 (Section 2.3),

In mass

production, Q is very large, P is very small, and

in mass customization. P

is very large, Q is very small (in the extreme Q = 1),

where P = product

variety (number of models), and Q = production quantity (units of

each model per year).

Along

with the trend toward more customized products, today's products have shorter

expected market lives. Mass production was justified by the existence of very

large markets for its mass produced goods. Mass markets have become fragmented,

resulting in a greater level of customization for each market.

In mass

production, products are produced based on sales forecasts. If the forecast is

wrong. this can sometimes result in large inventories of finished goods that

are slow in selling.

TABLE 27.4 Comparison of

Mass Production and Agile

Manufacturing

Agile

companies produce to order: customized products for individual customers. In-ventories

of finished products are minimized.

Products

today have a higher information content than products of yesterday. This is

made possible by computer technology. Think of the many products today that

operate based on integrated circuits. Nearly all consumer appliances are

controlled by l C chips, Modern automobiles use engine controllers that are

based on microprocessors. The personal computer market relies on the ability of

the customer to be able to telephone an 800 number for assistance. The same is

true of many appliances that are complicated to operate, for example, video

cassette recorders (VCRs). Manufacturers of these appliances keep adding more

and more features to gain competitive advantage, further complicating the

products

Single

time sales was the expectation of the merchandiser before agility. The customer

bought the product and was not expected to be seen again. Today, companies want

to nave continuing relationships with their customers, Automobile companies

want their customers to nave their new cars serviced at the dealer where the

car was purchased. This provides continuing service business for the dealer,

and when the customer finally decide, that the time is right to purchase a new

car, the first logical place to look for that new car is at the same dealer.

Finally,

pricing of the product is traditionally based on its cost. The manufacturer

calculates the costs that went into making the product find adds a markup to

determine the price (Example 2.8). But some customers are willing and able to

pay more. The product may be more valuable to them, especially if it is

customized for them. The marketplace allows different pricing structures for

different customers. Instead of standard prices for everyone, different prices

are used, according to the value to the customer, The airline industry is a

good example of multilevel pricing structure. Tourists who fly and stay over

Saturday night pay sometimes one third the airfare of business travelers who

travel round trip during the same week. Automobiles produced in the same final

assembly plant on the same body frame can vary in price by two to one depending

on options and nameplate. In the higher education industry, we have different

tuition rates for different students. We use a different lexicon tor the

lower rates than other industries use: We give a discount on the tuition price

and call it a scholarship.

Related Topics