Chapter: Mechanical : Design of Transmission Systems : Design of Transmission Systems for Flexible Elements

Solved Problems: Design of Transmission Systems for Flexible Elements

SOLVED PROBLEMS

1. Design a V – Belt drive to the following specifications Power transmitted = 75kw

Speed of driving wheel = 1440rpm

Speed of driven wheel = 400rpm

Diameter of driving wheel = 300mm

Center distance = 2500mm

Service = 16hrs/day

Solution

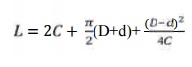

For the given power of 75 kw D type or E type belts are suited. Let us selected D type

belt.

Service factor = 1.5 (for heavy duty and 16 hrs/ day with ac motor high torque)

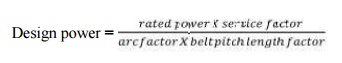

Pitch length

Now = 300 mm

The next standard pitch length = 7648mm

Corresponding inside length = 7569mm

Length factor = 1.05

Arc of contact

Initial Tension = 0.75%L

Final center distance = 2788 mm

Specification

Type of belt = D7569 50 IS294

Number of belts required = 8

Pitch diameter of small pulley = 1080mm

Center distance = 2788mm

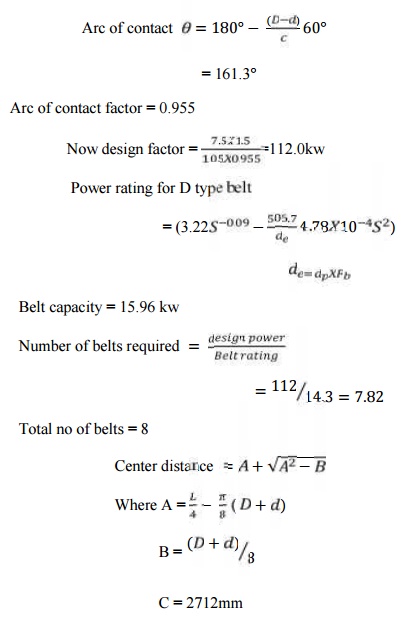

2. Design a Flat belt drive to transmit 25 kw at 720 rpm to an aluminium rolling machine the speed reduction being 3.0. The distance between the shaft is 3m.Diameter of rolling machine pulley is 1.2m.

Solution:

Given

Specification of the belt drive are

Dia of motor pulley are = 400mm

Dia of rolling machine pulley = 1200mm

Center distance = 30000 mm

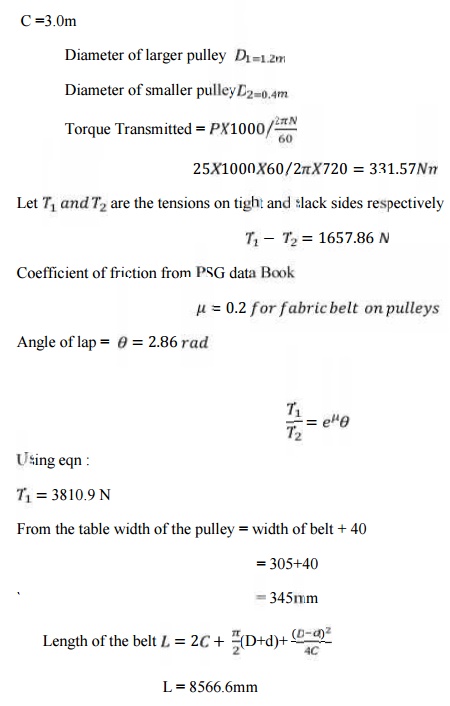

Width of belt = 305mm

Width of the belt = 345 mm

Width of pulleys = 345mm

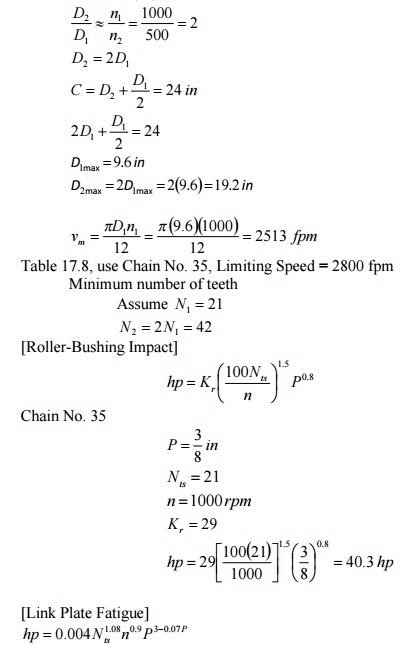

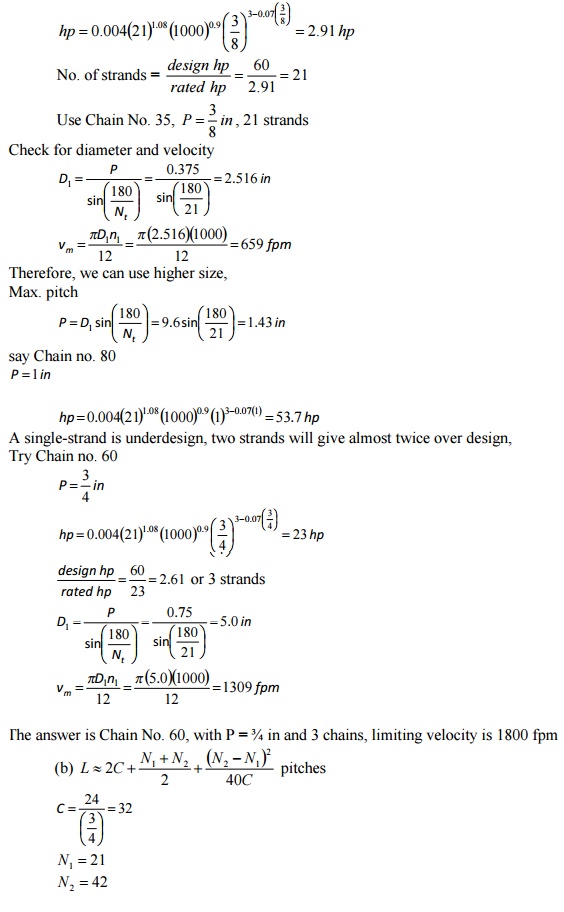

3.A roller chain is to be used on a paving machine to transmit 30 hp from the 4-cylinder Diesel engine to a counter-shaft; engine speed 1000 rpm, counter-shaft speed 500 rpm. The center distance is fixed at 24 in. The cain will be subjected to intermittent overloads of 100 %. (a) Determine the pitch and the number of chains required to transmit this power. (b) What is the length of the chain required? How much slack must be allowed in order to have a whole number of pitches? A chain drive with significant slack and subjected to impulsive loading should have an idler sprocket against the slack strand. If it were possible to change the speed ratio slightly, it might be possible to have a chain with no appreciable slack. (c) How much is the bearing pressure between the roller and pin?

Solution:

(a) design hp = 2(30) = 60 hp intermittent

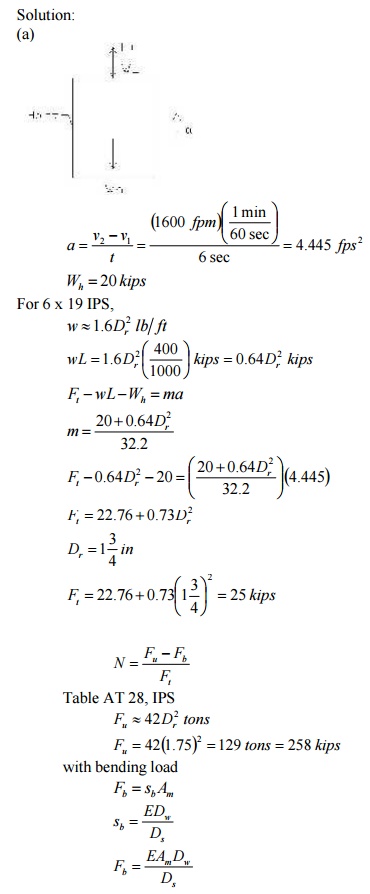

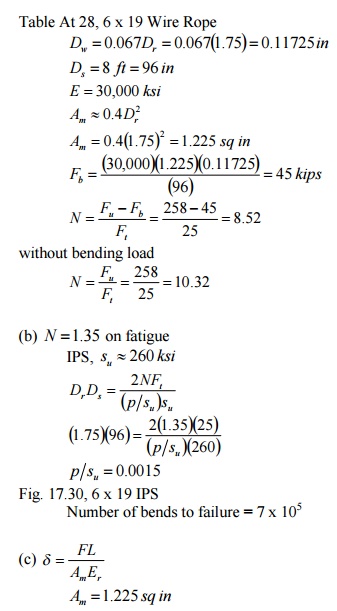

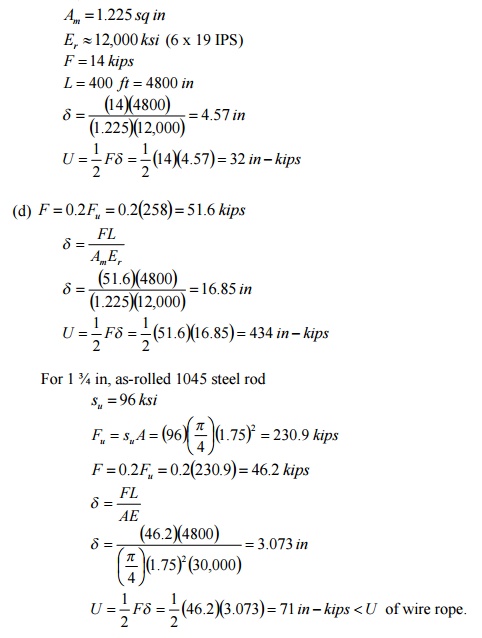

4.In a coal-mine hoist, the weight of the cage and load is 20 kips; the shaft is 400 ft. deep. The cage is accelerated from rest to 1600 fpm in 6 sec. A single 6 x 19, IPS, 1 ¾ -in. rope is used, wound on an 8-ft. drum. (a) Include the inertia force but take the static view and compute the factor of safety with and without allowances for the bending load. (b) If

N =1.35 , based on fatigue, what is the expected life? (c) Let the cage be at the bottom of the shaft and ignore the effect of the rope’s weight. A load of 14 kips is gradually applied on the

6-kip cage. How much is the deflection of the cable due to the load and the additional energy absorbed? (d) For educational purposes and for a load of 0.2Fu , compute the energy that this

400-ft rope can absorb and compare it with that for a 400-ft., 1 ¾ -in., as-rolled-1045 steel rod. Omit the weights of the rope and rod. What is the energy per pound of material in each case?

Related Topics