Chapter: Mechanical : Design of Transmission Systems : Design of Transmission Systems for Flexible Elements

Design of Transmission Systems for Flexible Elements

DESIGN OF TRANSMISSION SYSTEMS FOR FLEXIBLE

ELEMENTS

V- BELT

Selection of V belts and pulleys

ü Determine your drive requirements.

How much power do you need to transmit and at what speed?

INTRODUCTION:

V- Belts

are one type of flexible connectors for transmitting power from one pulley to

another pulley. Whose center distance is approx. 3M.thier cross section is

trapezoidal. The belts are operated on groove pulleys.

MATERIALS USED:

·

Cord

·

Fabric

·

Cotton

·

Rayon

POWER TRANSMISSION

Belts are

the cheapest utility for power transmission between shafts that may not be

axially aligned. Power transmission is achieved by specially designed belts and

pulleys. The demands on a belt drive transmission system are large and this has

led to many variations on the theme. They run smoothly and with little noise,

and cushion motor and bearings against load changes, albeit with less strength

than gears or chains. However, improvements in belt engineering allow use of

belts in systems that only formerly allowed chains or gears.

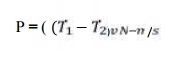

Power

transmitted between a belt and a pulley is expressed as the product of

difference of tension and belt velocity

P= (T1

-T2 ) v

where, T1

and T2 are tensions in the tight side and slack side of the belt respectively.

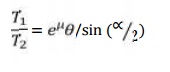

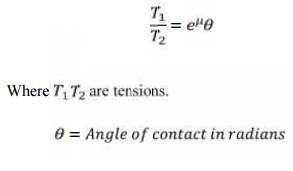

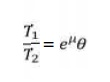

They are

related

as:

TYPES OF

V BELT

Generally

V belts are classified into various grades based on their power transmitting

capacity as A, B, C, D and E. the cross sectional areas are increased order

from A –E

SELECTION OF V BELTS AND PULLEYS

V belts

are designed based on

1. Fundamental

formula

2. Manufactures

catalogues

FUNDAMENTAL FORMULA:

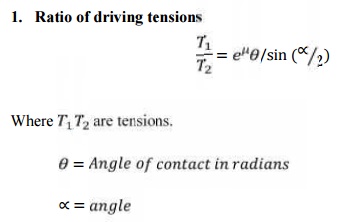

2. Power Transmitted by belt

MANUFACTURES CATALOGUES

1. At first based on amount of power to be

transmitted , select the type of belt

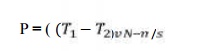

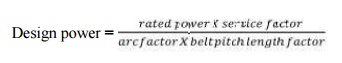

2. Calculate design power

Design power =

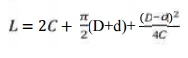

3. Pitch length

=

4. Note inside length

5. Determine Belt rating

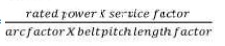

6. Design no of belts =

7. Correct the center Length

8. Also determine parameters of V groove

pulleys using Manufactures data

Selection of Flat belts and pulleys

INTRTODUCTION

Flat Belts are one type of flexible connectors for

transmitting power from one pulley to another pulley. Whose center distance is

approx. 5-15m

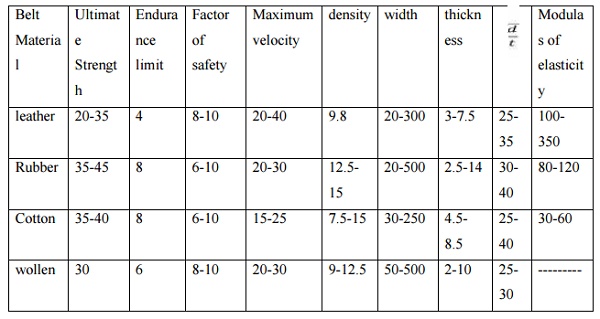

CHARACTERISTICS OF BELT:

TYPES OF FLAT BELT DRIVES:

1. Open belt

drive

2. Cross

belt drive

3. Quarter

turn drive

4. Belt

drive with idler pulley

5. Belt

drive with many pulleys

DESIGN OF FLAT BELTS

1. Using

fundamental formula

2. Using

Manufactures catalogues

FUNDAMENTAL FORMULA:

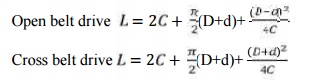

3. Ratio of driving tensions=

4. Power Transmitted by belt

MANUFACTURES CATALOGUES

1. How much

power to be transmitted

2. What may

be the power transmitting capacity

For

determining the design power and belt rating, we must consider certain factors

like service, arc of contactand so on.

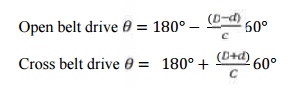

i. Arc of contact

ii. Load rating

The load

ratings have been developed for 180° of

arc of contact 10m/s belt speed per mm width.

iii. Length

of belt

Open belt drive Cross belt drive

iv.

Belt

tensions

1. Belt of 3

plies – 1.5% of L

2. Belt of

4,5,6 plies – 1% of L

3. Belt of 8

plies – 0.5% of L

v.

Pulley

width

Generally

the pulleys should be slightly wider than belt width.

POWER TRANSMISSION

Belts are

the cheapest utility for power transmission between shafts that may not be

axially aligned. Power transmission is achieved by specially designed belts and

pulleys. The demands on a belt drive transmission system are large and this has

led to many variations on the theme. They run smoothly and with little noise,

and cushion motor and bearings against load changes, albeit with less strength

than gears or chains. However, improvements in belt engineering allow use of

belts in systems that only formerly allowed chains or gears. Power transmitted

between a belt and a pulley is expressed as the product of difference of

tension and belt velocity

P = (T1-

T2) v

where, T1

and T2 are tensions in the tight side and slack side of the belt

respectively. They are

related

as:

DESIGN PROCEDURE

1. From the

given conditions like power, type of working conditions, diameters of pulleys,

speed ratio etc, determine maximum power

Desin

power = rated power x service factor x arc of contact factor

Select

service factor based on nature of load

and applications from PSG data book

2. Decide

the type of belt

3. Then

calculate the belt rating

4. Find the

reqired width by design power by belt capacity and adopt the standard available

5. Determine

the length of belt based on type of drive and reduce certain amount length

6. Find out

the pulley dimension and draw the arrangement of belt drive.

Wire ropes and pulleys

SELECTION PROCEDURE

1. Based on

the given data like nature of application, duty etc, select the type of rope

2. Estimate

the design load by multiplying the dead weight by three times design factor.

3. 3. Determine the net cross sectional area of the

rope by choosing specific strength of wire.

4. Find out

the diameter of rope

5. Select

the next standard dia of rope and note down the max breaking strength

6. Compute

the load applied at normal working acceleration and starting etc. find out the actual

factor of safety by dividing the breaking strength by above loads

7. For safe

design the actual factor of safety should not be less than 5 at any

circumstances

8. Then

calculate the drum and pulley dimensions.

Selection of Transmission chains and Sprockets

SELECTION PROCEDURE

1. Depending upon the amount amount of

power to be transmitted and another working conditions such as available space,

chain speed, position of chain drive etc

2. Assuming the center distance between

the chaun sprockets interms of pitches

3. Calculate the developed load for

breaking the chain using expression as

4. For determining pitch, choose

suitable chain from PSG Data Book

5. Find out the actual factor of safety

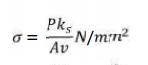

6. Determine the induced stress over the

projected area of the chain using the relation as

7. Find the length of chain and provide allowance for initial sagging.

=

8. Evaluate the pitch diameter of pinion

sprocket (d1) and wheel sprocket (d2)

9. Draw a neat sketch of chain drive

with calculated specifications.

SOLVED PROBLEMS

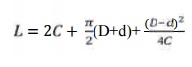

1. Design a V – Belt drive to the following specifications Power

transmitted = 75kw

Speed of

driving wheel = 1440rpm

Speed of

driven wheel = 400rpm

Diameter

of driving wheel = 300mm

Center

distance = 2500mm

Service =

16hrs/day

Solution

For the

given power of 75 kw D type or E type belts are suited. Let us selected D type

belt.

Service

factor = 1.5 (for heavy duty and 16 hrs/ day with ac motor high torque)

Pitch

length

Now = 300

mm

The next

standard pitch length = 7648mm

Corresponding

inside length = 7569mm

Length

factor = 1.05

Arc of

contact

Initial

Tension = 0.75%L

Final

center distance = 2788 mm

Specification

Type of

belt = D7569 50 IS294

Number of

belts required = 8

Pitch

diameter of small pulley = 1080mm

Center

distance = 2788mm

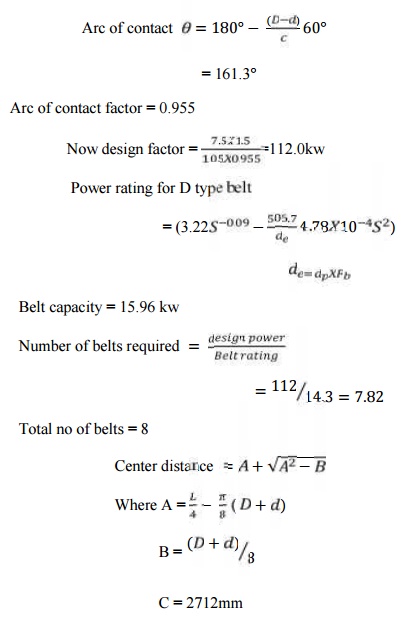

2. Design

a Flat belt drive to transmit 25 kw at 720 rpm to an aluminium rolling machine

the speed reduction being 3.0. The distance between the shaft is 3m.Diameter of

rolling machine pulley is 1.2m.

Solution:

Given

Specification

of the belt drive are

Dia of

motor pulley are = 400mm

Dia of

rolling machine pulley = 1200mm

Center

distance = 30000 mm

Width of

belt = 305mm

Width of

the belt = 345 mm

Width of

pulleys = 345mm

3.A

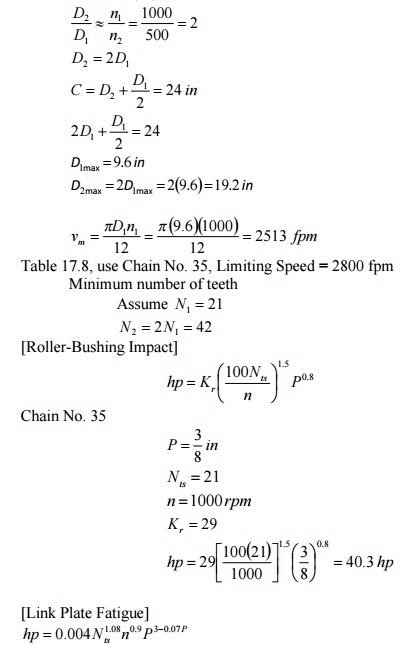

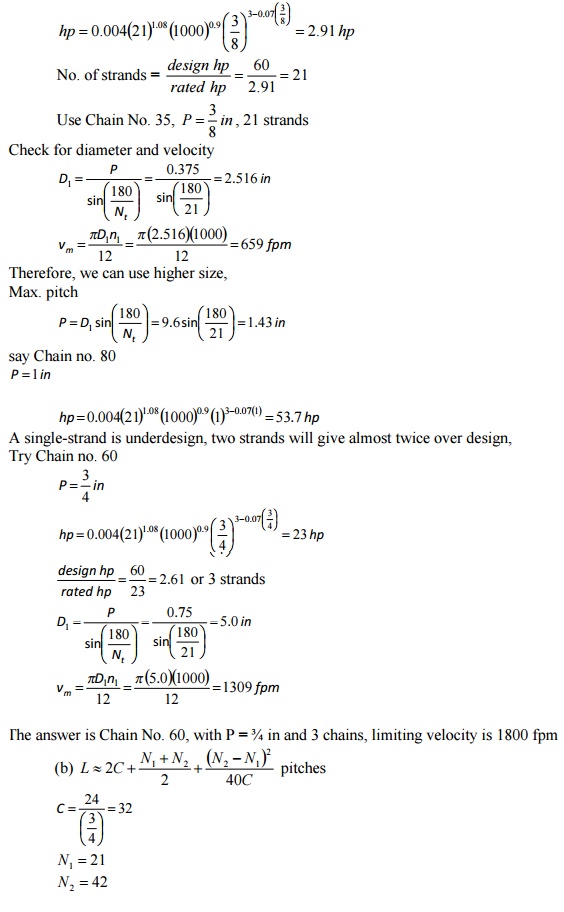

roller chain is to be used on a paving machine to transmit 30 hp from the 4-cylinder

Diesel engine to a counter-shaft; engine speed 1000 rpm, counter-shaft speed

500 rpm. The center distance is fixed at 24 in. The cain will be subjected to

intermittent overloads of 100 %. (a) Determine the pitch and the number of

chains required to transmit this power. (b) What is the length of the chain

required? How much slack must be allowed in order to have a whole number of

pitches? A chain drive with significant slack and subjected to impulsive

loading should have an idler sprocket against the slack strand. If it were

possible to change the speed ratio slightly, it might be possible to have a

chain with no appreciable slack. (c) How much is the bearing pressure between

the roller and pin?

Solution:

(a) design hp = 2(30) = 60 hp intermittent

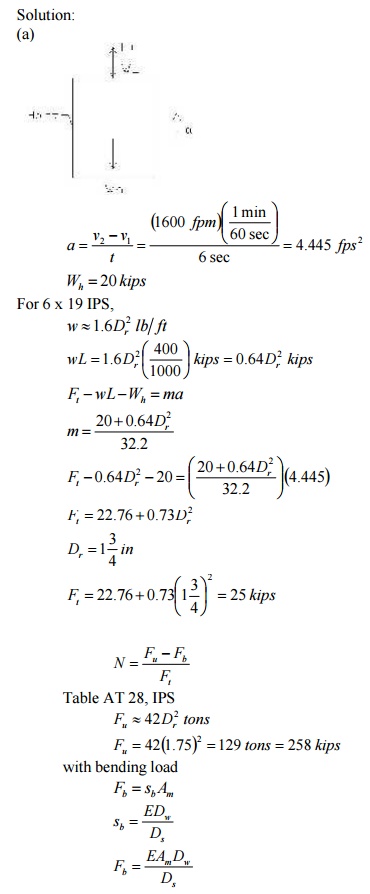

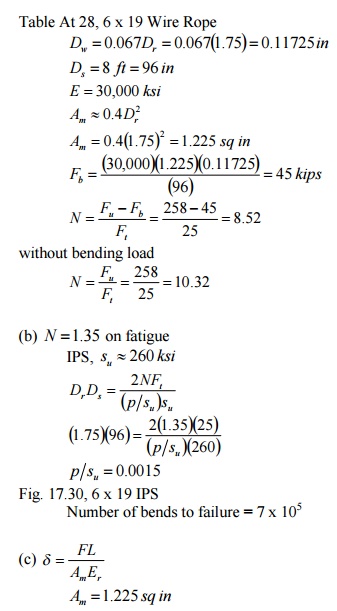

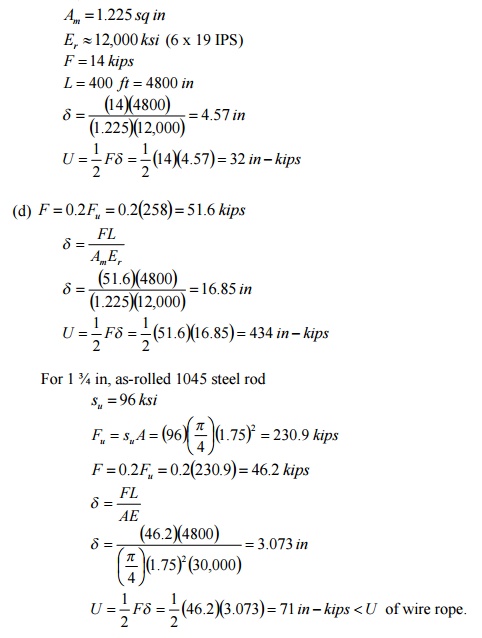

4.In a

coal-mine hoist, the weight of the cage and load is 20 kips; the shaft is 400

ft. deep. The cage is accelerated from rest to 1600 fpm in 6 sec. A single 6 x

19, IPS, 1 ¾ -in. rope is used, wound on an 8-ft. drum. (a) Include the inertia

force but take the static view and compute the factor of safety with and

without allowances for the bending load. (b) If

N =1.35 , based on fatigue, what

is the expected life? (c) Let the cage be at the bottom of the shaft and ignore the effect of the

rope’s weight. A load of 14 kips is gradually applied on the

6-kip

cage. How much is the deflection of the cable due to the load and the

additional energy absorbed? (d) For educational purposes and for a load of 0.2Fu , compute the energy that

this

400-ft

rope can absorb and compare it with that for a 400-ft., 1 ¾ -in.,

as-rolled-1045 steel rod. Omit the weights of the rope and rod. What is the

energy per pound of material in each case?

Related Topics