Chapter: Civil : Environmental Engineering : Sewage Treatment

Sewage Treatment: Screening and Pre aeration tanks

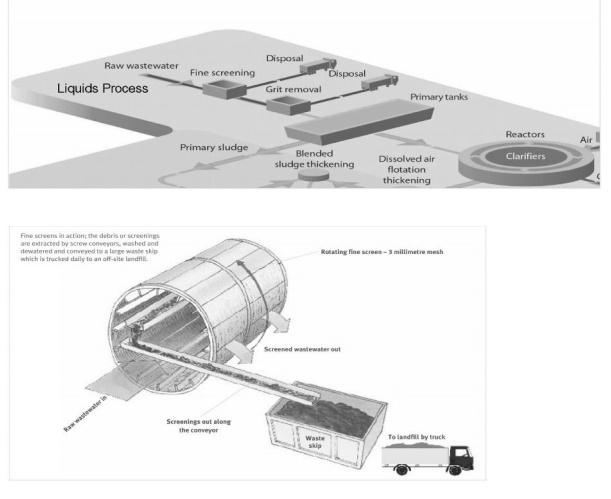

Screening

Screening is the first

line of treatment at the entrance to the wastewater treatment plant where six

new fine screens, arranged in parallel channels, intercept solid material in

the influent wastewater.

The fine screens

replace the old-technology (19 millimetre bar screens) and have a stainless steel

mesh with apertures of three millimetres. The drum-shaped screens are not

static pieces of equipment but are large revolving mechanisms, constantly

rotated by hydraulic drives. The screens break up the raw sewage flowing into

the plant and extract material such as paper, fruit and vegetable pulp,

plastic, wood and sanitary items.

Banks of water jets

within the rotating screens constantly blast the debris from the mesh. The

debris or screenings (up to eight tonnes per day) are extracted by screw

conveyors, washed and dewatered and conveyed to a large waste skip which is

trucked daily to an off-site landfill.

Pre-aeration tanks

The 12 grit removal tanks, also known as

pre-aeration tanks, are

14 metres x 12 metres

with a water depth of 4.6 metres. Each tank has a volume of 703 cubic metres

and is partially divided into two sections (north and south) with one air

sparge pipe and one grit ejector in each section.

Air, pumped from a perforated pipe running along the

side of the tank floors, generates a swirling motion which reduces the

effective density of the wastewater. This encourages the inorganic material

(finer than three millimetres), namely, sand, silt and fine gravel to settle

out. The aeration process also adds oxygen to the wastewater which, by the time

it reaches the treatment plant, can be oxygen deficient.

The

organic solids remain in suspension. The settled grit is collected in a hopper

at one end of the steeply sloping floor. Here grit pumps automatically extract

the grit and transfer it through a pipe network to grit washing facilities

above the truck loading bay. It is then removed by water ejection to a washing

tank and fed into another hopper by a screw conveyor where it is dewatered. The

extracted grit is trucked off-site for disposal in landfills

Related Topics