Chapter: Mechanical and Electrical : Thermal Engineering : Refrigeration and Air Conditioning

Refrigeration

REFRIGERATION

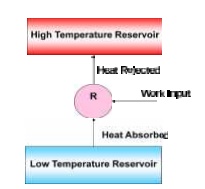

CONCEPT OF REFRIGERATION

Refrigeration is a pro cess in which work is done to move heat from one location to another. The work of heat trannsport is traditionally driven by mechanical work, but can also be driven by heat, magnetism , electricity, laser, or other means.

How does it work?

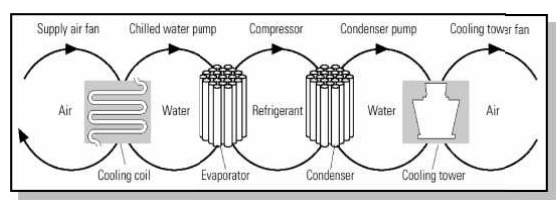

Thermal energy moves from left to right through five loops of heat trans fer:

1) Indoor air loop

2) Chilled water loop

3) Refrigerant loop

4) Condenser water loop

5) Cooling water loop

SIGNIFICANCE

Refrigeration has had a large importance on industry, lifestyle, a griculture and settlement patterns. The idea of preserving food dates back to the ancien t Roman and Chinese empires. However, refrigeration technology has rapidly evolved in the last century, from ice harvesting to temperature-controlled rail cars. In order to avoid food spoilage, refrigeration plays an important role in day to day life, similarly, Air conditioning is also an important technological system to prevent the human from the hot atmosphere during summer seasons.

CLASSIFICATION OF REFRIGERATION SYSTEM

Types of Refrigeratio n

• Vapour Compression Refrigeration (VCR): uses mechanical energy

• Vapour Absorption Re frigeration (VAR): uses thermal energy

Vapour Compression Refrigeration

• Highly compressed flu ids tend to get colder when allowed to expand

• If pressure high enough

• Compressed air hotter than source of cooling

• Expanded gas cooler than desired cold temperature

• Lot of heat can be rem oved (lot of thermal energy to change liquid to vapour)

• Heat transfer rate re mains high (temperature of working fluid mu ch lower than

what is being cooled)

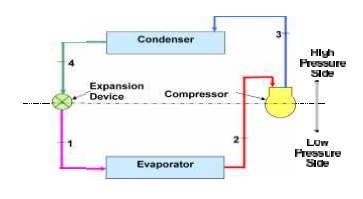

Vapour Compression Refrig eration Cycle

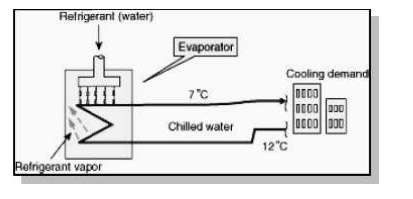

Evaporator

Low pressure liquid re frigerant in evaporator absorbs heat and changes to a gas

Compressor

The superheated vapo ur enters the compressor where its pressure is raised

Condenser

The high pressure sup erheated gas is cooled in several stages in the co ndenser

Expansion

Liquid passes through expansion device, which reduces its pressure an d controls the flow into the evaporator

Type of refrigerant

• Refrigerant determine d by the required cooling temperature

• Chlorinated fluorocarb ons (CFCs) or freons: R-11, R-12, R-21, R-22 and R-502

Choice of compressor, design of condenser, evaporator determined by

• Refrigerant

• Required cooling

• Load

• Ease of maintenance

• Physical space requirements

• Availability of utilities (water, power)

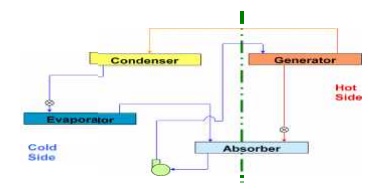

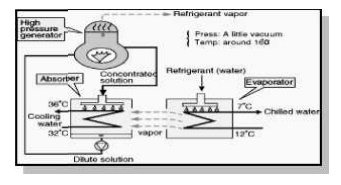

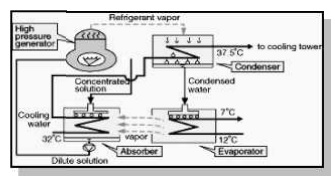

Vapour Absorption Refrigeration

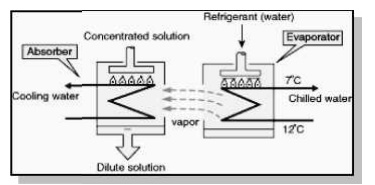

Evaporator

Absorber

High pressure generator

Condenser

Evaporative Cooling

• Air in contact with water to cool it close to ‘wet bulb temperature’

• Advantage: efficient cooling at low cost

• Disadvantage: air is ri ch in moisture

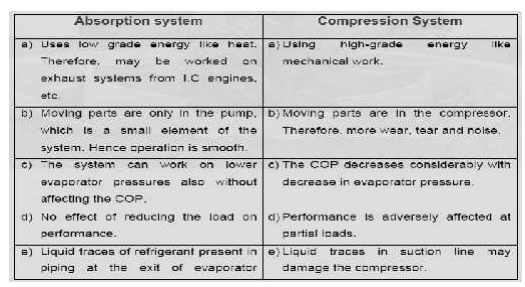

COMPARISON BETWEEN VAPOR COMPRESSION AND A BSORPTION SYSTEM

PERFORMANCE

Assessment of Refrigeration

• Cooling effect: Tons of Refrigeration

1 TR = 3024 kCal /hr heat rejected

• TR is assessed as:

TR = Q x×Cp x× ( Ti – To) / 3024

Q = mass flow rate of coolant in kg/hr

Cp = is coolant specific heat in kCal /kg °C

Ti = inlet, temperature of coolant to evaporator (chiller) in 0°C To = outlet temperature of coolant from evaporator (chiller) in 0°C

Specific Power Consumption (kW/TR)

• Indicator of refrigeration system’s performance

• kW/TR of centralized chilled water system is sum of

• Compressor kW/TR

• Chilled water pump kW/TR

• Condenser water pump kW/TR

• Cooling tower fan kW/TR

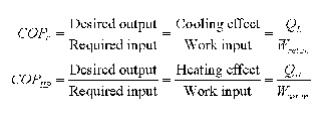

Coefficient of Performance (COP)

• The performance of refrigerators and heat pumps is expressed in terms of

coefficient of performance (COP), defined as

Measure

• Airflow Q (m3/s) at Fan Coil Units (FCU) or Air Handling Units (AHU): anemometer

• Air density r(kg/m3)

• Dry bulb and wet bulb temperature: psychrometer

• Enthalpy (kCal/kg) of inlet air (hin) and outlet air (Hout): psychrometric charts

APPLICATIONS OF REFRIGERATRION

Ø Metal workers

Ø Oil refineries

Ø Chemical plants

Ø Petrochemical plants

Ø Transporting temperature-sensitive foodstuffs

Ø Dairy products

Related Topics