Chapter: Mechanical and Electrical : Thermal Engineering : Refrig Eration and Air Conditioning

Refrigeration and Air Conditioning

REFRIGERATION AND AIR CONDITIONING

PREREQUISITE DISCUSSION

Before 1830, few Am ericans used ice to refrigerate foods due to

a lack of ice-storehouses and iceboxes. As these two things became more widely

available, individuals used axes and saws to harvestt ice for their

storehouses. This method proved to be difficult, dangerous, and certainly did

not resemble anything that could be du plicated on a commercial scale.

Despite the difficulti es of harvesting ice, Frederic Tudor

thought that he could capitalize on this new commo dity by harvesting ice in

New England and shipping it to the Caribbean islands as well as the southern

states. In the beginning, Tudor lost thousands of dollars, but eventually

turned a profit as he constructed icehouses in Charle ston, Virginia and in the

Cuban port town of Havana. These icehouses as well as better insulated ships

helped reduce ice wastage from 66% to 8%. This efficiency gain influen ced

Tudor to expand his ice market to othe r towns with icehouses such as New

Orleans a nd Savannah.

This ice market further expan ded as

harvesting ice became faster and cheap er after one of Tudor’s suppliers, Nathaniel Wyeth, invented a horse-drawn ice cutter in 1825. This

invention as well as Tudor’s s uccess inspired others to get involved in the

ice trade and the ice industry grew.

Ice became a mass-m arket commodity

by the early 1830s with the price of ice dropping from six cents per pound to a

half of a cent per pound. In New York City, ice consumption

increased from 12,000 tons in 1843 to 100,000 tons in 1 856. Boston’s consumption leapt from 6,00 0 tons to 85,000 tons during that

same period. Ice harvesting created a “cooling

culture” as majority of people used ice and iceboxes to

store their dairy products, fish, meat, and ev en fruits and vegetables. These

early cold storage practices paved the way for many Ame ricans to accept the

refrigeration technology that would soon take over the country.

CONCEPT

CONCEPT OF

REFRIGERATION

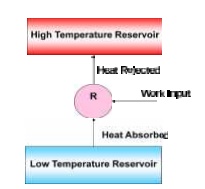

Refrigeration

is

a pro cess in which work is done to move heat from one location to another.

The work of heat trannsport is traditionally driven by mechanical work, but can

also be driven by heat, magnetism , electricity, laser, or other means.

How does

it work?

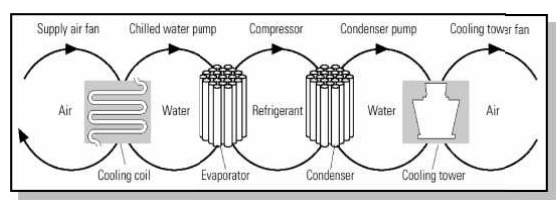

Thermal energy moves from left to right through

five loops of heat trans fer:

1) Indoor

air loop

2) Chilled

water loop

3) Refrigerant

loop

4) Condenser

water loop

5) Cooling

water loop

SIGNIFICANCE

Refrigeration has had a large importance on industry, lifestyle,

a griculture and settlement patterns. The idea of preserving food dates back to

the ancien t Roman and Chinese empires. However, refrigeration technology has

rapidly evolved in the last century, from ice harvesting to

temperature-controlled rail cars. In order to avoid food spoilage,

refrigeration plays an important role in day to day life, similarly, Air

conditioning is also an important technological system to prevent the human

from the hot atmosphere during summer seasons.

CLASSIFICATION OF

REFRIGERATION SYSTEM

Types of Refrigeratio n

•

Vapour Compression Refrigeration (VCR): uses

mechanical energy

•

Vapour Absorption Re frigeration (VAR): uses

thermal energy

Vapour Compression

Refrigeration

•

Highly compressed flu ids tend to get colder when

allowed to expand

•

If pressure high enough

•

Compressed air hotter than source of cooling

•

Expanded gas cooler than desired cold temperature

• Lot of

heat can be rem oved (lot of thermal energy to change liquid to vapour)

• Heat

transfer rate re mains high (temperature of working fluid mu ch lower than

what is

being cooled)

Vapour

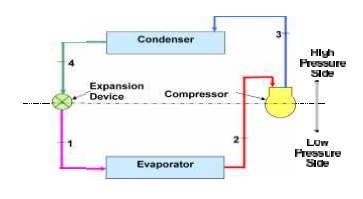

Compression Refrig eration Cycle

Evaporator

Low

pressure liquid re frigerant in evaporator absorbs heat and changes to a gas

Compressor

The

superheated vapo ur enters the compressor where its pressure is raised

Condenser

The

high pressure sup erheated gas is cooled in several stages in the co ndenser

Expansion

Liquid

passes through expansion device, which reduces its pressure an d controls the

flow into the evaporator

Type of refrigerant

•

Refrigerant determine d by the required cooling

temperature

•

Chlorinated fluorocarb ons (CFCs) or freons: R-11,

R-12, R-21, R-22 and R-502

Choice of compressor, design of condenser,

evaporator determined by

•

Refrigerant

•

Required cooling

•

Load

•

Ease of maintenance

•

Physical space requirements

•

Availability of utilities (water, power)

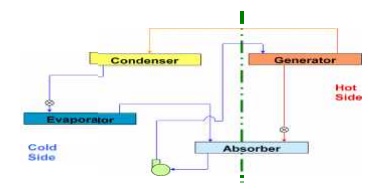

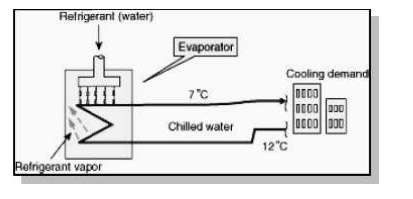

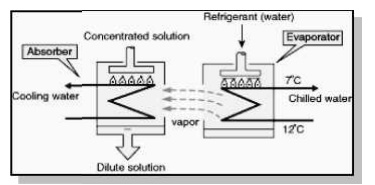

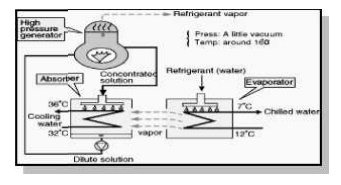

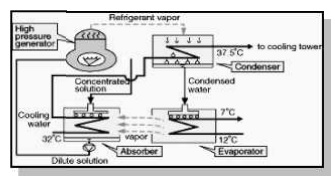

Vapour Absorption Refrigeration

Evaporator

Absorber

High pressure generator

Condenser

Evaporative Cooling

•

Air in contact with water to cool it

close to ‘wet bulb temperature’

•

Advantage: efficient cooling at low cost

•

Disadvantage: air is ri ch in moisture

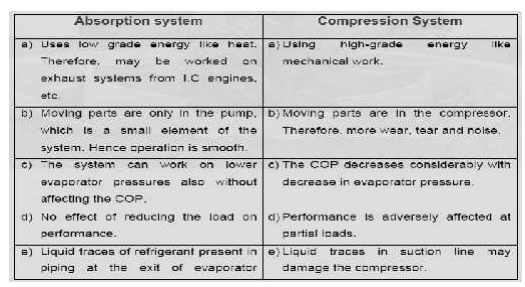

COMPARISON

BETWEEN VAPOR COMPRESSION AND A BSORPTION SYSTEM

PERFORMANCE

Assessment of Refrigeration

•

Cooling effect: Tons of Refrigeration

1 TR = 3024

kCal /hr heat rejected

•

TR is assessed as:

TR

= Q x×Cp x× ( Ti – To) /

3024

Q = mass flow rate of coolant in

kg/hr

Cp = is coolant specific heat in kCal

/kg °C

Ti = inlet, temperature of

coolant to evaporator (chiller) in 0°C To = outlet temperature of coolant from

evaporator (chiller) in 0°C

Specific Power Consumption (kW/TR)

•

Indicator of refrigeration system’s

performance

•

kW/TR of centralized chilled water system is sum

of

•

Compressor kW/TR

•

Chilled water pump kW/TR

•

Condenser water pump kW/TR

•

Cooling tower fan kW/TR

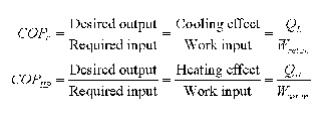

Coefficient of Performance (COP)

•

The

performance of refrigerators

and heat pumps

is expressed in

terms of

coefficient of performance (COP), defined as

Measure

•

Airflow Q (m3/s) at Fan Coil Units (FCU) or Air

Handling Units (AHU): anemometer

•

Air density r(kg/m3)

•

Dry bulb and wet bulb temperature: psychrometer

•

Enthalpy (kCal/kg) of inlet air (hin) and

outlet air (Hout): psychrometric charts

APPLICATIONS OF

REFRIGERATRION

Ø Metal

workers

Ø Oil

refineries

Ø Chemical

plants

Ø Petrochemical

plants

Ø Transporting temperature-sensitive foodstuffs

Ø Dairy products

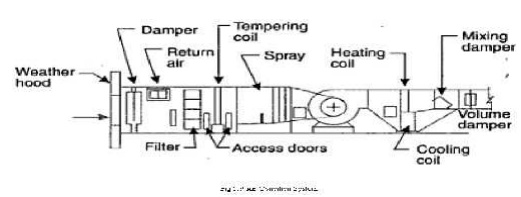

AIR CONDITIONERS

CONCEPT OF AIR CONDITIONING

Air

conditioning (often referred to as aircon, AC or A/C) is the process of

altering the properties of air (primarily temperatureand humidity) to more

favourable conditions, typically with the aim of distributing the conditioned

air to an occupied space to improve thermal comfort and indoor air quality.

TYPES OF AIR CONDITIONERS

•

Room air conditioners

•

Zoned Systems

•

Unitary Systems

•

Window Air-conditioning System

•

Split Air-conditioning System

•

Central air conditioning systems

1 ROOM AIR CONDITIONER

•

Room air conditioners cool rooms rather than the

entire home.

•

Less expensive to operate than central units

•

Their efficiency is generally lower than that of

central air conditioners.

•

Can be plugged into any 15- or 20-amp, 115-volt

household circuit that is not shared with any other major appliances

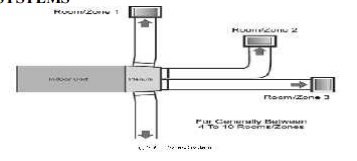

2 ZONED SYSTEMS

3 CENTRAL AIR CONDITIONING

•

Circulate cool air through a system of supply and

return ducts. Supply ducts and registers (i.e., openings in the walls, floors,

or ceilings covered by grills) carry cooled air from the air conditioner to the

home.

•

This cooled air becomes warmer as it circulates

through the home; then it flows back to the central air conditioner through

return ducts and registers

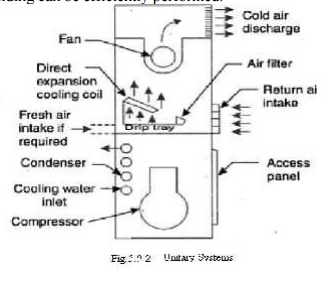

4.UNITARY

SYSTEMS

A unitary

air conditioning system comprises an outdoor unit including a compressor for

compressing a refrigerant, an outdoor heat exchanger for heat exchange of the

refrigerant and an expander connected to the outdoor heat exchanger, for

expanding the refrigerant; a duct installed inside a zone of a building; a

central blower unit having a heat exchanger connected to the outdoor unit

through a first refrigerant pipe and a blower for supplying the air

heat-exchanged by the heat exchanger to the duct; and an individual blower unit

including a heat exchanger connected to the outdoor unit through a second

refrigerant pipe and a fan for sending the air heat exchanged by the heat

exchanger and disposed in a zone in the building, for individually cooling or

heating the zone. Accordingly, cooling or heating operation is performed on

each zone of the building, and simultaneously, additional individual heating or

cooling operation can be performed on a specific space, so that a cost can be

reduced and cooling or heating in the building can be efficiently performed.

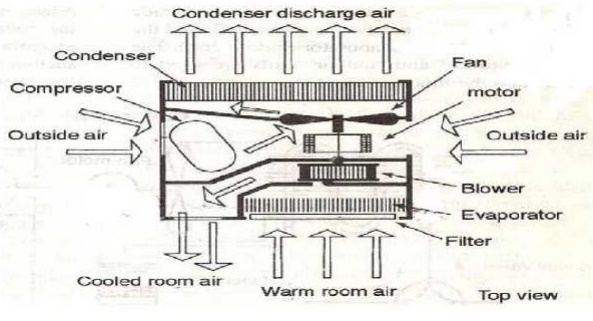

5.WINDOW AIR-CONDITIONING

SYSTEM

It is the

most commonly used air conditioner for single rooms. In this air conditioner

all the components, namely the compressor, condenser, expansion valve or coil,

evaporator and cooling coil are enclosed in a single box. This unit is fitted

in a slot made in the wall of the room, or often a window sill. Windows air

conditioners are one of the most widely used types of air conditioners because

they are the simplest form of the air conditioning systems. Window air

conditioner comprises of the rigid base on which all the parts of the window

air conditioner are assembled. The base is assembled inside the casing which is

fitted into the wall or the window of the room in which the air conditioner is

fitted. The whole assembly of the window air conditioner can be divided into

two compartments: the room side, which is also the cooling side and the outdoor

side from where the heat absorbed by the room air is liberated to the

atmosphere. The room side and outdoor side are separated from each other by an

insulated partition enclosed inside the window air conditioner assembly. In the

front of the window air conditioner on the room side there is beautifully

decorated front panel on which the supply and return air grills are fitted (the

whole front panel itself is commonly called as front grill). The louvers fitted

in the supply air grills are adjustable so as to supply the air in desired

direction. There is also one opening in the grill that allows access to the

Control panel or operating panel in front of the window air conditioner.

TYPES OF CENTRAL AC

•

split-system

•

An outdoor metal cabinet contains the condenser

and compressor, and an indoor cabinet contains the evaporator

•

Packaged

•

The evaporator, condenser, and compressor are all

located in one cabinet.

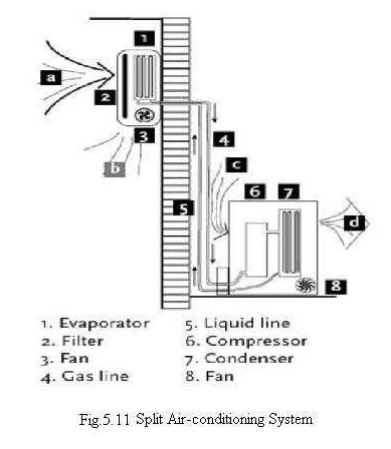

6 SPLIT AIR-CONDITIONING SYSTEM:

The split

air conditioner comprises of two parts: the outdoor unit and the indoor unit.

The outdoor unit, fitted outside the room, houses components like the

compressor, condenser and expansion valve. The indoor unit comprises the

evaporator or cooling coil and the cooling fan. For this unit you don't have to

make any slot in the wall of the room. Further, the present day split units

have aesthetic looks and add to the beauty of the room. The split air

conditioner can be used to cool one or two rooms.

Energy Consumption

•

Air conditioners are rated by the number of

British Thermal Units (Btu) of heat they can remove per hour. Another common

rating term for air conditioning size is the "ton," which is 12,000

Btu per hour.

•

Room air conditioners range from 5,500 Btu per

hour to 14,000 Btu per hour.

Energy Efficiency

•

Today's best air conditioners use 30% to 50% less

energy than 1970s

•

Even if your air conditioner is only 10 years old,

you may save 20% to 40% of your cooling energy costs by replacing it with a

newer, more efficient model

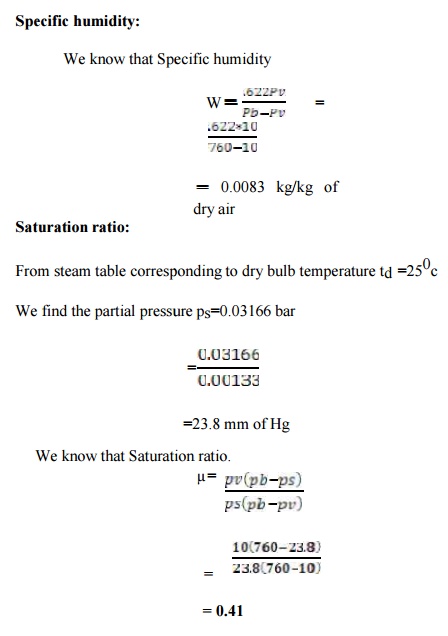

SOLVED PROBLEMS

1. A sling

psychrometer gives reading of 250c dry bulb temperature 1 50c

wet bulb temperature. The barome ter indicates 760 mm of hg assuming partial

pressure of the vapour as 10 mm of Hg. Determine 1. Specific humidity 2.

Saturation ratio.

Given

Data:

Dry

bulb temper ature td =250c

Wet bulb tempe rature tw=150c Barometer

pressure pb=760mm of Hg

Partial

pressure pv= 10mm of Hg

To

Find:

Specific

humidit y

Saturation

ratio.

Solution:

Specific

humidity:

We

know that Specific humidity

= 0.41

Result:

1. Specific

humidity 0.0083 kg/kg of dry air

2. Saturation

ratio . = 0.41

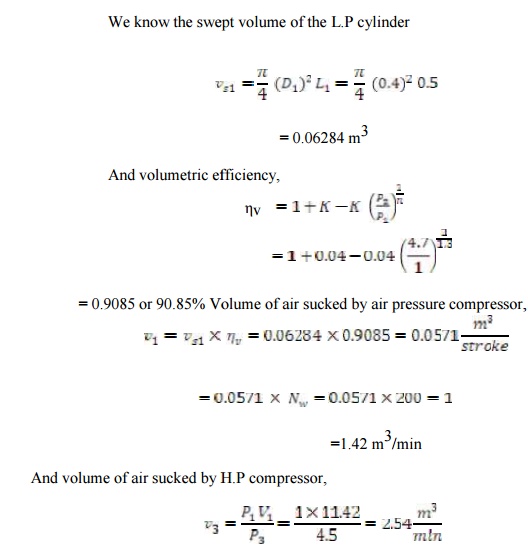

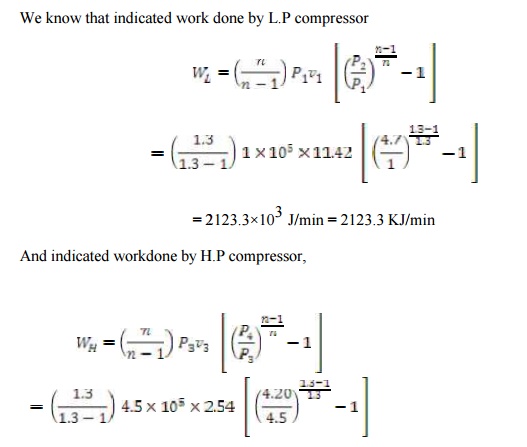

2. A two stages, single acting

air compressor compresses air to 20bar. The air enters the L.P cylinder at 1bar

a nd 27oc and leaves it at 4.7bar. the air en ters the H.P. cylinder

at 4.5bar and 27oc. the size of the L.P cylinder is 400mm diameter

and 5 00mm stroke. The clearance volume In both cylinder is 4% of the

respective stroke volume. The compressor runs at 200rpm, taking index of

compression and expansi on in the two cylinders as 1.3, estimate 1. The

indicated power required to run the co mpressor; and 2. The heat rejected in

the intercooler per minute.

Given data:

Pressure

(P4)= 20bar

Pressure

(P1) = 1 bar = 1× 105 N/m2

Temperature (T1 ) = 27oC = 27+273 =

300K Pressure (P 2) = 4.7bar

Pressure

(P3) = 4.5bar

Temperature (T3 ) = 27oC = 27+273 =

300K Diameter ( D1) = 400mm 0.4m Stroke (L1) = 500 mm = 0.5m

K = 0.04

N

= 200rpm ; n = 1.3

To Find:

Indicated

power required to run the compressor

Solution :

=

2 043.5× 103 J/min = 2034.5 KJ/min

Total

indicated work done by the compressor,

W

= WL + WH = 2123.3 + 2034.5

=

4157.8 KJ/min

Indicated

power required to run the compressor = 4157.8 / 60

=

69.3KW

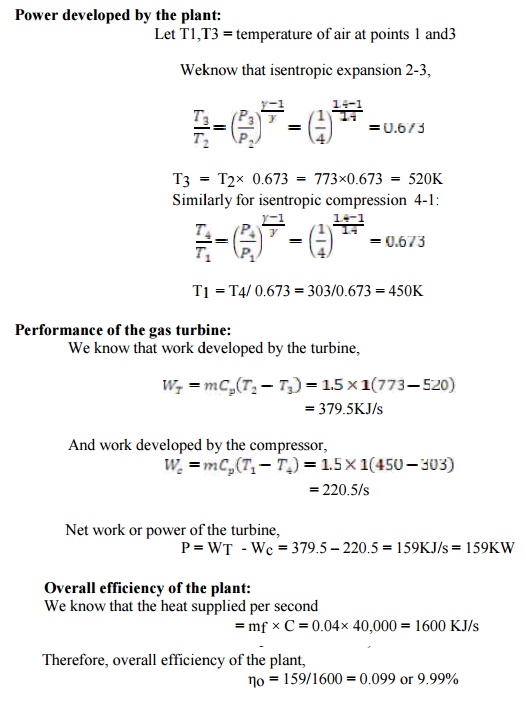

3. In an oil gas turbine installation , air is

taken as 1 bar and 30oC . The air is compressed

to 4bar and then heated by b

urning the oil to a temperature of 500oC . If the air flows at the

rate of 90Kg/min . Find the power developed by the plant take γ for air

as 1.4 Cp as 1KJ/KgK . If 2.4Kg of oil having calorific value of 40,000 KJ/Kg

if b urned in the combustion chamber per min ute. Find the overall efficiency

of the plant.

Given

Data:

Pressure (P4 = P3) = 1bar Pressure (P1 = P2) =

4bar

Temperature

(T2) = 500oC = 500+273 = 773K

Mass flow rate of air(ma) =

90Kg/min = 1.5Kg/sec Mass flow rate of fuel (mf) = 2.4Kg/min = 0.04Kg/sec

Temperature (T4) = 30oC = 30+273 = 303K

γ

= 1.4

; Cp = 1KJ/KgK ; Cv= 40,000 KJ/Kg

To

Find:

Power developed by

the plant

Performance of the

gas turbine

Overall

efficiency of the plant

Solution:

TECHNICAL

TERMS

BTU - British

thermal unit. A unit of heat energy - approximately the amount of energy needed to heat one pound of water by one degree

Fahrenheit.

dBA – a unit for measuring sound power or pressure,

deciBel on the A scale.

Capacity – the ability of a heating or cooling system to heat

or cool a given amount of space.

For heating, this is usually expressed

in BTU’s. For cooling, it is usually given in tons.

Compressor – the pump that moves the refrigerant from the

indoor evaporator to the outdoor condenser

and back to the evaporator again. The compressor is often called “the heart of

the system” because it circulates the refrigerant through the

loop.

Condenser – a device used to condense a refrigerant thereby

rejecting the heat to another source, typically

an air cooled or water cooled condenser.

Cassette – a fan coil unit that fits mainly in the ceiling

void with only a diffuser plate visible, diffuses

conditioned air in one, two, three or four directions.

HVAC – heating, ventilation and air conditioning.

Inverter

system – Constantly

alters fan and motor speeds. This enables faster cooling of a room, and the inverter air conditioner doesn’t

have to switch itself on and off to maintain a constant

temperature.

kw – standard measurement of heat or power, 1kw = 1000

watts = 3412Btu/hr = 860kcal.

Load

Calculation – a

mathematical design tool used to determine the heat gain and heat loss in a building so that properly sized air

conditioning and heating equipment may be installed.

Refrigerant – a substance that produces a refrigerating effect

while expanding or vaporizing.

Reverse

cycle – the

reverse cycle air conditioner internally reverses its operation to provide heating or cooling, as required.

Split System

– a central air conditioner consisting of two or

more major components. The system

usually consists of a compressor-containing unit and condenser, installed

outside the building and a non-compressor –

containing air handling unit installed within the building. This is the most

common type of system installed in a home.

Zoning – the practice of providing independent heating

and/or cooling to different areas in a structure.

Zoning typically utilizes a system controller, zoning dampers controlled by a

thermostat in each zone, and a bypass damper to regulate static pressure in the

supply duct.

Related Topics