Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Industrial Control Systems

Process Industries Versus Discrete Manufacturing Industries

PROCESS INDUSTRIES VERSUS DISCRETE MANUFACTURING INDUSTRIES

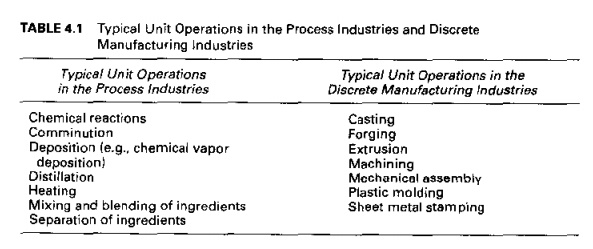

In OUI previous discussion of industry types in Chapter 2, we divided industries and their production operations into two basic categories: (1) process industries and (2) discrete manufacturing industries (Section 2.1). Process industries perform their production operations on amounts of materials, because the materials tend to be liquids, gases, powders, and similar materials, whereas discrete manufacturing industries perform their operations on quannties of materials, because the materials tend to be discrete parts and products. The kinds of unit operations performed on the materials are different in the two industry categories. Some of the typical unit operations in each category are listed in Table 4.1.

Levelsof Automation in the Two Industries

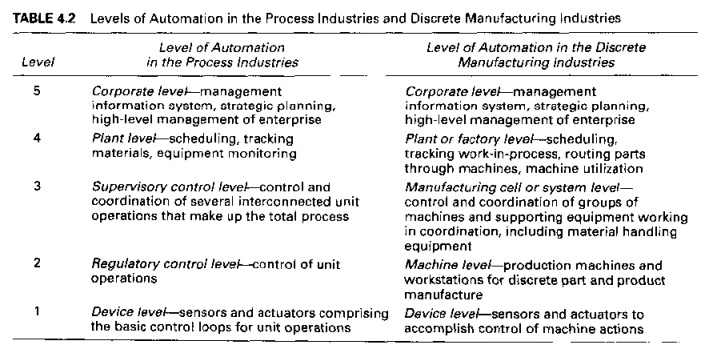

The levels of automation (Section 3.3) in the two industries are compared in Table 4.2. The significant differences are seen in the low and intermediate levels. At the device level, there are differences in the types of actuators and sensors used in the two industry categories. simply because the processes and equipment are different. In the process industries, the devices are used mostly for the control loops in chemical, thermal, or similar processing operations, whereas in discrete manufacturing, the devices control the mechanical actions of machines. At the ncxt level above, the difference is that unit operations art: controlled in the process industries, and machines are controiled in the discrete manufacturing operations. At the third level, the difference is between control of interconnected unit processing operations and interconnected machines.At the upper levels (plant and enterprise), the control issues are similar, allowing for the fact that the products and processes are different.

Variables and Parameters in the Two Industries

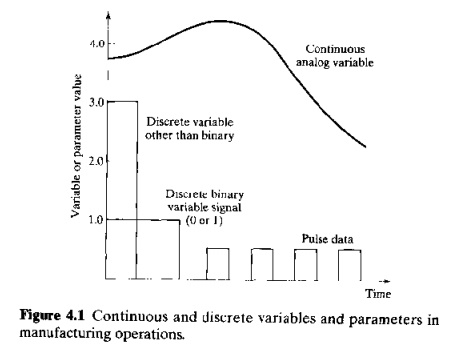

The distinction between process industries and discrete manufacturing industries extends to the variables and parameters that characterize the respective production operations. The reader will recall from the previous chapter [Section 3.1.2) that we defined variables as outputs of the process and parameters as inputs to the process. In the process industries. the variables and parameters of interest tend to be continuous, whereas in discrete manufacturing, they tend to be discrete. Let us explain the differences with reference to Figure 4.1.

A continuous variable (or parameter) is one that is uninterrupted as time proceeds. at least during the manufacturing operation. A continuous variable is generally considered to be analog, which means it can take on any value within a certain range. The variable is not restricted to a discrete set of values. Production operations in both the process industries and discrete parts manufacturing are characterized by continuous variables. Examples include force:, temperature, flow rate, pressure, and velocity. All of these variables (whichever ones apply to a given production process) arc continuous over time during the process, and they can take on any of an infinite number of possible values within a certain practical range,

A discrete variable (or parameter) is one that can take on only certain values within a given range. The most common type of discrete variable is binary, meaning it can take on either of two possible values, ON or OFF, open or closed, and so on. Examples of discrete binary variables and parameters in manufacturing include: limit switch open or closed, motor on or off, and workpart present or not present in a fixture. Not all discrete variables (and parameters) are binary. Other possibilities are variables that can take on more than two possible values but less than an infinite number, that is, discrete variobles other than binary. Examples include daily piece counts in a production operation and the display of a digital tachometer. A special form of discrete variable (and parameter) is pulse data, which consist of a train of pulses as shown in Figure 4.1.As a discrete variable, a pulse train might be used to indicate piece counts; for example, parts passing on a conveyor activate a photocell to produce a pulse for each part detected. As a process parameter, a pulse train might be used to drive a stepper motor.

Related Topics