Chapter: Mechanical : Manufacturing Technology : Metal Casting Process

Patterns

Patterns

Patterns are the replica or physical models of the final required shape of the casting, made by wood (teak,magony,pine), plastics, Metals, Plaster of paris etc.,

1Types of patterns

1.Solid pattern 2.Split piece pattern 3.Three piece pattern 4.Loose piece pattern 5.Match plate pattern 6.Segmental pattern 7.Sweep patten 8.skeleton Pattern 9.shell Pattern.

2Pattern Allowance.

Allowance are the extra dimensional compensation give to the pattern in order to attain the correct shape and size of the final solidified metal casting.Five types of allowances were taken into consideration for various reasons. They are

2.1.Shrinkage allowance

Any metal when heated to liquid stage and solidified will undergo change in dimension. Mostly the dimension of the product will be reduced, then the actual size of the pattern. Hence the patterns are made slightly in larger dimensions.(3%-5%)

2.2.Draft allowance

It will be difficult to remove the pattern from the mould cavity (without disturbing the mould) after ramming of sand. Hence the pattern (wooden or metal pattern) is slightly given 2 o– 3 o TAPER in the z - axis or vertical direction.

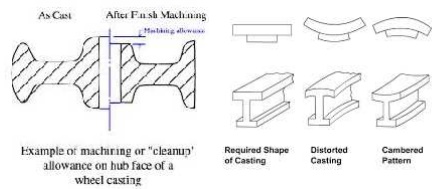

2.3. Finish allowance

It is otherwise called as machining allowance .The pattern is made slightly 5mm -10mm large in dimension than the required final part dimension. After casting the extra material is removed from the solidified material by machining.

2.4.Shake or Rapping allowance.

Before withdrawing the pattern it is rapped and thereby the size of the mould cavity increases. Actually by rapping , the external sections move outwards increasing the size and internal sections move inwards decreasing the size. This allowance is kept negative and hence the pattern is made slightly smaller in dimensions 05.1.0 mm.

2.5.Distortion allowance.

Some material might tend to bend or distort from the actual size or dimensions. Hence the pattern is give counter balance degree or angle of recess so that the material will be in the required dimension when solidified in the mould cavity.

Related Topics