Chapter: Modern Analytical Chemistry: Kinetic Methods of Analysis

Methods Based on Chemical Kinetics: Instrumentation

Instrumentation

Quantitative information about a chemical

reaction can be made using any of the techniques described in the

preceding. For reactions that are kineti-

cally slow, an analysis may

be performed without

worrying about the

possibility that significant changes in concentration

occur while measuring the signal. When the reaction’s rate

is too fast,

which is usually

the case, significant errors may be introduced if changes in concentration are ignored. One solution to this

problem is to stop, or quench, the reaction

by suitably adjusting experimental conditions. For example, many reactions involving enzymes show a strong pH dependency and may be quenched by adding a strong acid

or strong base.

Once the reaction

is stopped, the concentration of the desired species can be deter- mined at the analyst’s convenience. Another approach is to use

a visual indicator that changes color after

the reaction occurs

to a fixed extent. You may recall

that this variable-time method is the basis of the so-called “clock reactions” com- monly used to demonstrate kinetics in the general chemistry

classroom and labo- ratory. Finally, reactions with fast

kinetics may be monitored continuously using the same types of spectroscopic and electrochemical detectors found in chro- matographic instrumentation.

Two additional

problems for chemical

kinetic methods of analysis

are the need to control

the mixing of the sample and reagents in a rapid and repro- ducible fashion and the

need to control

the acquisition and

analysis of the

signal. Many kinetic determinations are made early

in the reaction when pseudo-zero- order or pseudo-first-order conditions are in effect.

Depending on the rate of re- action, measurements are typically made within a span of a few

milliseconds or seconds. This

is both an advantage and

a disadvantage. The

disadvantage is that transferring

the sample and reagent to

a reaction vessel and their subsequent

mixing must be automated

if a reaction with rapid kinetics is to be practical. This usually requires a dedicated instrument, thereby adding an additional ex- pense to the analysis. The advantage is that a rapid, automated analysis allows for a high throughput of samples. For example, an instrument for the automated ki- netic analysis of

phosphate, based on reaction 13.9, has achieved sampling rates of 3000 determinations per hour.

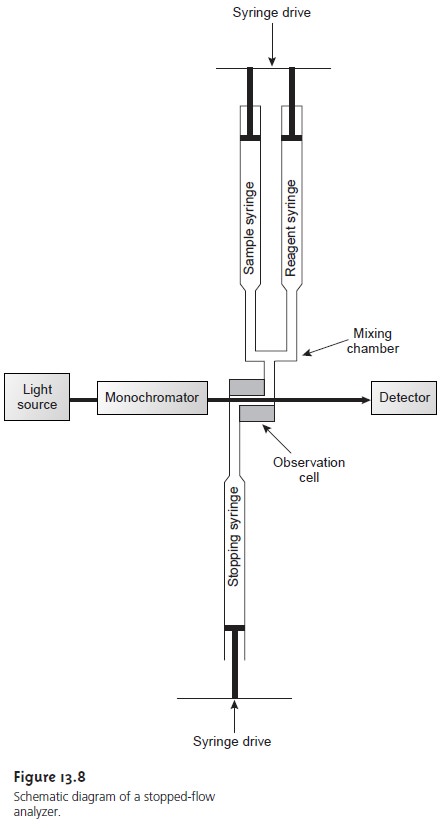

A variety of designs have

been developed to automate kinetic

analyses.6 The

stopped-flow apparatus, which is shown

schematically in Figure

13.8, has found use in kinetic determinations involving very fast

reactions. Sample and

reagents are loaded into separate syringes, and precisely measured

volumes are dispensed by the action of a syringe

drive. The two solutions are rapidly mixed in the mix-

ing chamber before flowing through

an observation cell.

The flow of sample and reagents

is stopped by applying back pressure with the stopping syringe. The back pressure

completes the mixing,

after which the reaction’s progress

is moni- tored spectrophotometrically. With a stopped-flow apparatus, it is possible to complete

the mixing of sample and reagent and initiate the kinetic measure-

ments within approximately 0.5 ms. The stopped-flow apparatus shown in Figure

13.8 can be modified by attaching an automatic sampler

to the sample sy- ringe,

thereby allowing the

sequential analysis of multiple samples. In this way the stopped-flow apparatus can be used for the routine

analysis of several

hun- dred samples per hour.

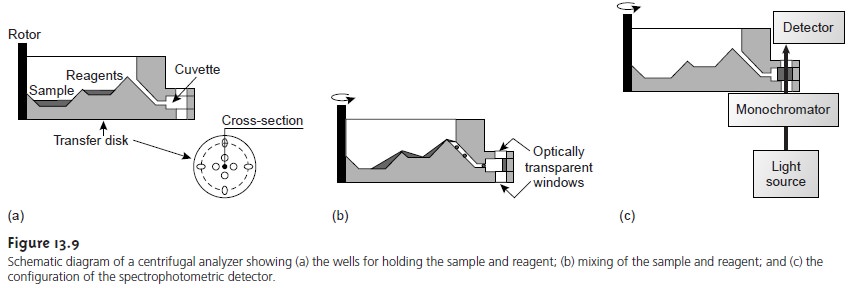

Another automated approach to kinetic analyses is the centrifugal analyzer, a partial cross section of which is shown in Figure 13.9. In this technique

the sample and reagents are placed in separate wells

oriented radially around

a circu- lar transfer disk

attached to the

rotor of a centrifuge. As the centrifuge spins, the sample and reagents are pulled by the centrifugal force to the cuvette, where mixing occurs.

A single optical

source and detector, located above and

below the transfer disk’s outer edge,

allows the absorbance of the reaction

mixture to be measured as it passes through the optical beam. The centrifugal analyzer allows a number of samples to be analyzed simultaneously. For example, if a transfer plate contains 30 cuvettes

and rotates with a speed

of 600 rpm, it is possible to collect 10 data points

per sample for each second

of rotation.

The ability to collect kinetic

data for several

hundred samples per hour is of

little consequence if the analysis

of the data must be accomplished manually. Be- sides time,

the manual analysis

of kinetic data is limited

by noise in the detector’s signal and the accuracy

with which the analyst can determine reaction

rates from tangents drawn

to differential rate

curves. Not surprisingly, the development of automated kinetic analyzers was

paralleled by the development of analog

and digital circuitry, as well as computer software

for the smoothing, on-line integra-

tion and differentiation, and analysis

of kinetic signals.

Related Topics