Chapter: Mechanical : Manufacturing Technology : Metal Forming Process

Metal Forming Process

METAL

FORMING PROCESS

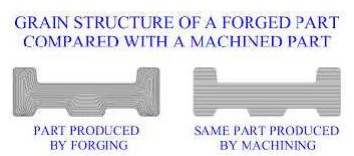

The Materails to be used in

places where the component is subjected to very high Impact load, Shock Load,

intermittant load and in Power transmission lines, Need to be produced with

dense grain structure. This requirement can be acheived by manufacturing

process such as Forging, Rolling,Extrusion and Drawing.

COMPARISION

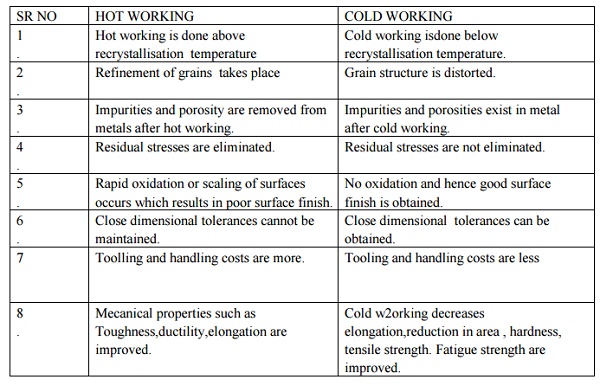

BETWEEN HOT WORKING AND COLD WORKING

HOT

WORKING

1.

Hot working is done

above recrystallisation temperature

2.

Refinement of

grains takes place

3.

Impurities and porosity

are removed from metals after hot working.

4.

Residual stresses are

eliminated.

5.

Rapid oxidation or

scaling of surfaces occurs which results in poor surface finish.

6.

Close dimensional

tolerances cannot be maintained.

7.

Toolling and handling

costs are more.

8.

Mecanical properties

such as Toughness,ductility,elongation are improved.

COLD

WORKING

1.

Cold working isdone

below recrystallisation temperature.

2.

Grain structure is

distorted.

3.

Impurities and

porosities exist in metal after cold working.

4.

Residual stresses are

not eliminated.

5.

No oxidation and hence

good surface finish is obtained.

6.

Close dimensional

tolerances can be obtained.

7.

Tooling and handling

costs are less

8.

Cold w2orking decreases

elongation,reduction in area , hardness, tensile strength. Fatigue strength are

improved.

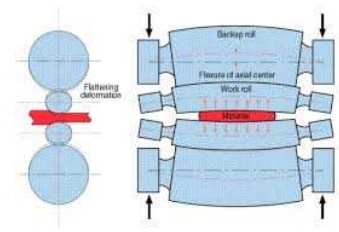

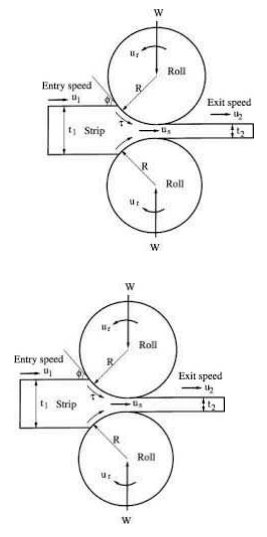

ROLLING

Rolling is the most rapid method

of forming metals into desired shapes by plastic deformation in between rolls.

The

forming of bars, plates , sheets, rails

and other steel sections are produced by

rolling.

1.Classification

of Rolling mill based on number of

rolls.

1.Two High Rolling Mill.

2.Three high Rolling Mill

3.Four high Rolling Mill

4. Multi Rolling Mill.

5.Universal Rolling Mill

6.Planetary Rolling Mill.

1.Two High Rolling Mill.

2.

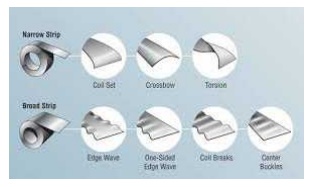

DEFECTS IN ROLLED PARTS

There are two types of major defects on the rolled products.

(a) SURFACE

DEFECTS

(b) INTERNAL

SURFACE DETECTS.

(a) SURFACE

DEFECTS Major surface defects on rolled products are scales, rust, scratches,cracks,

and pits. These defects occurs on the rolled products due to the impurities and

inclusions present in the original cast materials.,

(b).INTERNAL SURFACE DEFECTS

i. WAVINESS OR WAVY EDGES.

It occurs due to the bending of rolls. The rolls

acts as a straight beam. If the material flow is continuous and to maintain

this continuity, strains with in the material should adjust with itself. There

are compressive strain on the edges and tensile strain at the centre. The edges

are restrained from expanding freely in the longitudinal direction because of

which wavy edges on the sheet will be produced.

ii. Zipper Cracks

It occurs due to poor material ductility, at the

rolling temperatureCamber is provided to avoid this defect., Camber is

providing slightly large diameter at the center of rolls than that at the

edges.

iii. FOLDS

Folds

occur if the reduction per pass is very less.

iv. Alligatoring.

It is the splitting of work piece along the

horizontal plane on exit, with top and bottom part following the rotation of

their respective rolls.

v. Lamination.

These are

small cracks which may develop when reduction in thickness is excessive.

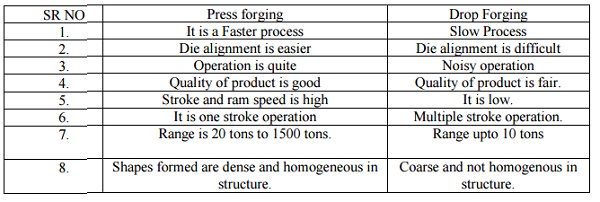

FORGING

1.

COMPARISON BETWEEN PRESS FORGING AND DROP FORGING.

SR NO Press forging : Drop Forging

1. It is

a Faster process : Slow Process

2. Die

alignment is easier : Die alignment is difficult

3. Operation

is quite : Noisy operation

4. Quality

of product is good : Quality of product is fair.

5. Stroke

and ram speed is high : It is low.

6. It is

one stroke operation : Multiple stroke operation.

7. Range

is 20 tons to 1500 tons. : Range upto 10 tons

8. Shapes

formed are dense and homogeneous in structure.

: Coarse and not homogenous in structure.

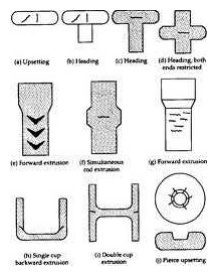

2.

Forging operations

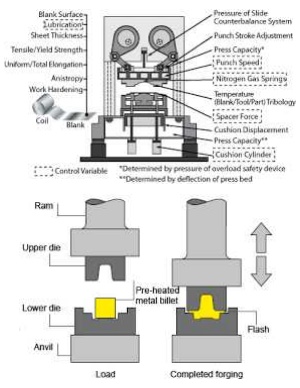

Forging is a process in which the work piece is

shaped by compressive forces applied through various dies and tools. It is one

of the oldest metalworking operations. Most forgings require a set of dies and

a press or a forging hammer. A Forged metal can result in the following: -

Decrease in height, increase in section - open die

forging Increase length, decrease cross-section, called drawing out.

Decrease length, increase in cross-section on a

portion of the length - upsetting

Change length, change cross-section, by squeezing in

closed impression dies - closed die forging. This results in favorable grain

flow for strong parts

3. Types

of forging

Closed/impression die forging

Electro-upsetting

Forward extrusion

Backward extrusion

Radial forging

Hobbing

Isothermal forging

Open-die forgig

Upsetting

Nosing

Coining

Commonly used materials include

• Ferrous

materials: low carbon steels

• Nonferrous

materials: copper, aluminum and their alloys

3.1Open-Die Forging

Open-die forging is a hot forging process in which

metal is shaped by hammering or pressing between flat or simple contoured dies.

Equipment. Hydraulic presses, hammers.

Materials. Carbon and alloy steels, aluminum

alloys, copper alloys, titanium alloys, all forgeable materials.

Process Variations. Slab

forging, shaft forging, mandrel forging, ring forging, upsetting between

flat or curved dies, drawing out.

Application. Forging ingots, large and

bulky forgings, preforms for finished forgings.

Closed Die Forging

In this process, a billet is

formed (hot) in dies (usually with two halves) such that the flow of metal from

the die cavity is restricted. The excess material is extruded through a

restrictive narrow gap and appears as flash around the forging at the die

parting line.

Equipment. Anvil and counterblow hammers,

hydraulic, mechanical, and screw presses.

Materials. Carbon and alloy steels, aluminum

alloys, copper alloys, magnesium alloys, beryllium, stainless steels,

nickel alloys, titanium and titanium alloys, iron and nickel and cobalt super

alloys.

Process Variations. Closed-die

forging with lateral flash, closed-die forging with longitudinal flash,

closed-die forging without flash.

Application.

Production

of forgings for automobiles, trucks, tractors, off-highway equipment,

aircraft, railroad and mining equipment, general mechanical industry, and

energy-related engineering production.

4.DEFECTS IN FORGED PARTS

1.Unfilled Sections.

In this some of the die cavity are not completely filled by

the flowing metal.

2.Cold Shuts.

This

appears as small cracks at the corners of the forging. Caused due to improper

design of die.

3.Scale Pits.

This is seen as irregular depositions on the

surface of forging. This is primarily caused because of improper cleaning of

the stock used for forging.

The

oxides and scales gets embedded into the finish forging surface.

When the

forging is cleaned by pickling, these are seen

as deputations on the forging

surfaces.

4.Die Shifts.

This is caused by the mis-alignment of the half

dies, making the two halves of te forging to be of improper shape. It is also

called as mismatch.

5..Flakes.

These are basically ruptures caused by the

improper cooling of the large forging. Rapid cooling causes the exterior to

cool quickly causing internal fractures.

6.Improper Grain Flow.

Due to improper design of the

die, which makes the flow of the metal to be not in the final intended

direction?

7.Laps.

Laps are

formed by webbuckling during forging. To avoid laps web thickness should be

increased and properly edesigned.

Related Topics