Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Suburban Railways in Metro Cities

Mass Rapid Transit System in Delhi

Mass Rapid Transit System in Delhi

At the time of independence, the

population of Delhi was a mere 0.6 million. Starting from this humble figure,

the population of the metropolis grew to 5.7 million in 1981, 12 million in

1998, and 13.78 million in 2001. In the absence of an efficient mass transport

system, the number of motor vehicles in Delhi has increased from 3 million in

1998 to about 5 million in 2006. The large number of vehicles lead to

congestion on roads, which leads to a slowing down of vehicular speeds, thereby

resulting in fuel wastage, increased air pollution, and an increase in road

accidents.

It is a well-known fact that out

of all the cities in the country, the process of urbanization has been the

fastest in Delhi. The city witnesses about 11.7 million transit trips per day,

of which no less than 62% are by public transport. Among the various public

transport options available, 99% are road based and only 1% are rail based,

despite the fact that Delhi has 144 route kilometres of rail tracks converging

into the city from five different directions.

In 1989 a study for an MRTS

network for Delhi was undertaken at the instance of the Delhi Government. The

report brought out the urgent need for a rail-based transit system comprising a

network of 181 route km that consisted of 29.5 km of underground alignments,

40.5 km of elevated route, and 111 km of surface/elevated route length. Nearly

99 km of the route length was analogous with the existing rail network and was

proposed as a surface (or at-grade) corridor. This scheme, which was the basis

of the Delhi Master Plan 2001, however, remained unimplemented.

Corridors for MRTS

There are two distinct types of corridors planned for the MRTS

in Delhi.

Rail corridor The

system is basically located on the surface (at-grade) or on elevated

ground and works on 25-kV ac traction and consists of a rolling stock with

sealed doors and windows that remain closed while in motion.

Metro corridor The

system is underground except for depot connections and lines, which may

be partly at-grade.

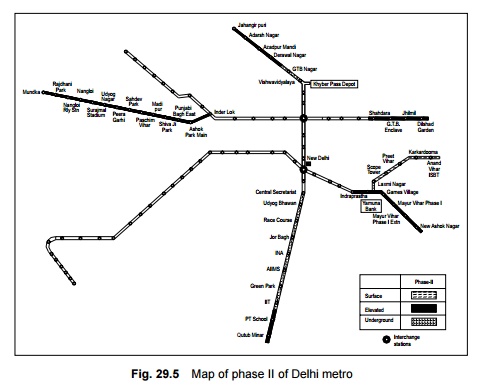

1 Phase I of Delhi Metro System

Once the Government decided to

take up the Delhi metro project, the Delhi metro rail corporation (DMRC) was

set up in 1995 for the implementation and subsequent operation of the Delhi

MRTS. The DMRC, however, became effectively functional in 1998, after the

appointment of general consultants and a team to execute the project.

Before starting with the

implementation of the project, the corridors included in phase I were reviewed

and it was finally decided to include three corridors covering a route length

of 62.1 km, which included 12.1 km of underground, 38.2 km of elevated, and

11.8 km of at-grade alignment (Fig. 29.4). The first phase of the Delhi metro

system consists of three lines, as presented in Table 29.1.

The Government decided to take up

the first phase of the metro system in August 1996. The project was started in

right earnest in 1998 and was completed in December 2005.

2 Technical Details of

Delhi Metro

The Delhi metro is planned on the

lines of a world class metro and is equipped with modern communication and

train control systems. In the Delhi metro system, trains are available at a

three-minute frequency during peak periods. The entrances and exits of metro

stations are monitored by flap doors operated by smart cards. For the

convenience of commuters, an adequate number of escalators are installed at the

metro stations. A special feature of the Delhi metro will be its integration

ultimately with other modes of public transport, enabling the commuters to

interchange between one mode and another. The technical details and design

parameters of the Delhi Metro system are briefly described below.

Rolling stock

The rolling stock is the mainstay

of a metro rail system. Metro coaches are lightweight, air-conditioned coaches

with stainless steel bodies that are equipped with features such as three-phase

ac motors. All systems in the coach are monitored by a microprocessor-based

train integrated management system (TIMS). All coaches are of the same type and

each coach is able to accommodate nearly 380 passengers. The coaches have a

width of 3.2 m and an overall length of 22 m (including sitting and standing

passengers).

Some of

the important features of the metro rolling stock are listed below.

(a) Automatic

electric door closing mechanism.

(b) All doors

fully open within 2.5 sec and fully close within 2.5 to 3.5 sec.

(c) The train

cannot move unless all the doors are properly closed and automatically locked.

(d) The train

can be halted with the application of the emergency brake, should a door open

during running.

(e) Emergency

evacuation facility in the form of emergency front door.

(f) Emergency

illumination and ventilation in the case of a power failure.

The initial plan involves running four-coach trains, each

consisting of two motor

coaches that are out fitted with

propulsion equipment and two driving trailer coaches, with a total carrying

capacity of 1500 passengers. Subsequently, six-coach and eight-coach trains are

likely to run to meet increasing traffic demands. These trains are planned to

run at an average speed of 32 to 35 km/hr over an average interstation distance

of 1.1 to 1.3 km.

Signalling and train control

Delhi metro trains are provided with

the latest signalling technology and control system as described in the

subsequent paragraphs.

Signalling It has

been decided that the trains plying underground and in surface corridors

will run at a 3-minute interval in peak hours. The signalling system is

designed for an ultimate headway of two minutes, with a continuous automatic

signalling system comprising of the following special features.

Automatic train protection Automatic

train protection will consist of cab signalling, whereby the

drivers will get information as regards the condition of the line beforehand

and so that they can control the speed of the trains in advance as per the

track status or obstruction. Normally the driver will apply the brakes in the

case of any perceived obstruction on the track. In case a driver fails to do

so, the emergency brakes are applied automatically and all these events are

recorded in the appropriate system device for the purpose of establishing

accountability.

Automatic train supervision Automatic

train supervision (ATS) is a sophisticated computer-based

supervisory system, which will take over the critical functions of the

controller in the control room and will drastically reduce the workload of the

station master. The assistance of ATS is necessary in cases where trains run at

a close headway of 2 minutes. The train describer system of ATS displays the

positions of the trains while they are in motion in visual form in the control

room as well as provide precise information with regard to passengers.

Automatic train operation This

feature is required to be provided for underground corridors

only. It enables the train to be driven without any human intervention, thereby

providing a high level of operational efficiency.

Interlocking of yards An

advanced interlocking system with high-speed (50 km/ hr) turnouts has

been recommended for the yards. The entire section is to be circuited with

audio frequency track circuits, which should eliminate any failures on account

of the insulated joints giving way, thus requiring replacement.

Telecommunication The

telecommunication network between various stations and services is like

a backbone of optic fibre, which will have an enormous capacity for channelling

data and voice communication. It will carry all train control information

through telemetry links, which will bear the details regarding the running of

the train and also the data collected by the passenger information system.

Passengers information system In the

system that has been proposed, the central train describer will provide

precise information to the passengers at every platform on a real time basis by

furnishing online information through the central computer. All the stations

will be provided with centrally synchronized clocks on the various platforms to

maintain time standards. The public address system will enable centralized as

well as local announcements on all stations platforms.

CCTV system Closed

circuit TVs are provided at all the critical locations in the station

premises to monitor every safety aspect.

Power supply

To ensure the continuous

availability of quality power for the running of metro trains, the utmost

efforts have been made to plan and design a power supply system with the degree

of reliability found in other world class metros. The Delhi metro system

derives its operating power in the form of 25-kV ac traction.

Tracks

The design standards for the

track of the metro system are briefly described in the following paragraphs.

Spacing of tracks The metro

routes consist of two broad gauge tracks spaced 4.10 m apart, which is

less than the 4.725 m standard spacing on Indian Railways. The reduced spacing

has been feasible due to the fact that the doors of the coaches are closed and

none of the doors open outward as is the case with the goods wagons of Indian

Railways. The points and crossings are 1 in 12 and 1 in 8.5, as in the case of

Indian Railways.

Gradients The

steepest gradient permissible is 3.0%. Gradients steeper than 2.5% are

adopted only in exceptional cases.

Curves Curves of

radius less than 450 m are adopted sparingly on running lines. No curve

on a running line may have a radius less than 300 m.

Tracks on stations On

stations, tracks are not to be laid on gradient steeper than 0.1% (1 in

1000) and they should also not be laid on curves with radius less than 1000 m.

Vertical curves normally have a radius of 2500 m at points where there is a

change in the gradient. In the case of transition curves, the rules followed

are the same as those on Indian Railways. The other features of the metro track

are as follows.

(a) The metro

track consists of 60-kg UIC rails on level tracks, which rest on concrete

sleepers and are fixed using elastic fastenings (Pandrol clip mark 11). The

sleeper density is 1660 sleepers per km.

(b) The

ballast cushion is prepared using hard stone ballast and measures 300 mm in

thickness.

(c) 60-kg

head hardened rails have been used to enhance the service life of the rails,

particularly on sharp curves and steep gradients.

(d) To

minimize the need for track maintenance and reduce the dimensions of structures

that are consequential to the quality of the run, a 'ballastless track' is

being laid on elevated sections, viaducts, and tunnels. These stretches are

provided with 60-kg rails that are fixed with the help of Vossloh fastenings.

(e) To

improve the standard of maintenance and ensure a comfortable ride, rails are

mostly welded as long welded rails and efforts have been made to ascertain that

the entire track is almost 'joint-less'. For this purpose, even the turnouts

have been integrated into the long welded rails. Specially designed turnouts

are used with thick web switches and CMS crossings by means of welded leg

extensions.

Metro stations

There are about 53 metro

stations, including 12 underground stations on phase 1 of the Delhi metro.

Metro stations are normally two-line stations with side or island platforms.

The platforms are 185 m long, so as to accommodate eight-coach trains. The

platform surface lies 1.08 m above the rail level, so that the floor of the

coaches is almost level with the platform. The width of the platform is

normally 6 m in the case of side platforms and 10 m in the case of island

platforms.

Tracks at stations with side

platforms are placed 4.1 m apart, while these with island platforms, are placed

around 13.3 m apart. Stations located in well-populated areas are normally

spaced 1 km apart. The interstation distance can, however, vary marginally to

suit site conditions.

Stations situated on an elevated

corridor along the central verge of the road can be provided with tracks at a

height of about 12 m above the road level. Most of the underground metro

stations are generally two-level stations between 270 m to 300 m in length. A

typical station is 20 m wide and 15 m deep. The first level boasts of various

passenger facilities together with ventilation and electronics and

communication equipment rooms and the lower level comprises the platform with

electric equipment rooms at each end of the box. Island platforms are provided

with stations that are adjacent to board tunnel sections while side platforms

are provided with cut and cover tunnels. All stations have been designed with

the option to accommodate platform screen doors.

3 Civil Works

Some of the new technologies and

innovations in construction techniques that are being deployed for the Delhi

MRTS are briefly mentioned here.

Construction of bridges

Several innovative construction

techniques were used in the construction of the bridges. For example, a new

Yamuna bridge (12 spans of 46.2 m each) was constructed using modern techniques

during the construction of the Delhi Metro. The substructure of this bridge

consists of capsule-shaped piers that rest on well (caisson) foundations of 10

m diameter with a steining thickness of 1.0 m, which have been sunk up to a

depth of about 39 m. The 'jack-down' method, supplemented with air/water

jetting, has been used for sinking the wells. This method involved pushing the

well assembly down into the ground by applying pressure to counter the

resistance arising due to skin friction around the periphery of the wells and

below the cutting edge. Soil dredging has been carried out inside the well

simultaneously. The new techniques resulted in the faster sinking of the wells.

Also, the wells have been sunk plumb into the water with the help of minimum

tilts or shifts.

The superstructure of the bridge

comprises of a single box girder of a constant depth of 3.5 m that has been

launched using an incremental launching technique. This technique involved

casting the girder on the bridge approach behind the abutment in segments of

length 23.1 m, which is half the length of one span. Each segment has been cast

behind the previous unit. After a sufficient concrete strength was attained,

the new unit was post-tensioned to the previous one. The assembly of units was

pushed forward to permit the casting of the succeeding segment. This technique

resulted in a single continuous girder of a length of 554 m with no joints.

The

innovative features of the Yamuna bridge are summarized below.

(a) Second

incrementally launched bridge in India, the first being the Panvel Nadi bridges

of the Konkan Railway.

(b) First box

girder in India carrying dual unballasted tracks.

(c) An

innovative technique for sinking the wells; the jack-down method has been

adopted for sinking 15 wells. Ground anchors have been installed near the well

staining, which have been used for taking the reaction of the specially

designed hydraulic jacks at the top.

Elevated viaduct

The elevated viaduct simply

comprises of supported spans with lengths varying from 21.1 m to 29.1 m. It has

been constructed by the precast segmental technique with epoxy bonded joints

and traditional internal pre-stressing. The span lengths have been determined

mainly on the basis of the site constraints at the ground level for the

location of the foundations and piers. All precasting has been done at a

centralized casting yard.

An aesthetic form of the

substructure has been evolved so as to harmonize with the flow of the forces.

In this structure the pier gradually tapers outward at the top to support the

bearings under the box webs. All the piers have been cast in place using rigid

steel which was poured in a single attempt in order to avoid any construction

joints. The use of bolts in the concrete has not been permitted. Bored piles of

a diameter of 1.2 m that have been cast in situ have been included by employing

modern hydraulic rigs. To ensure a standard span, groups of nine piles with a

length of 23 m to 28 m have been stacked in the soil. In rocky terrains, piles

have been stacked in the rock in groups of six up to a depth equal to 1.5 to

3.0 times the diameter of the pile, depending on the type of rock encountered.

A temporary casing has been employed for the stabilization of the bore holes.

Cut and cover tunnels

It is possible to construct

tunnels by excavating the ground surface, hence the cut and cover method has

been employed for tunnel construction in these stretches. Cut and cover tunnels

are generally designed as a single structural unit with a dividing wall, and

walkways for each track giving an average box width of 10 m. The over-run

tunnels are used as sidings and contain three tracks while at the depot spur

the tunnels contain four tracks. The construction methodology for cut and cover

tunnels is similar to that of cut and cover stations.

Cut and cover construction,

though economical, results in a lot of public inconvenience if planned

improperly. As such, it requires exhaustive planning with regard to utilities,

traffic management, and environmental concerns such as cutting of trees and air

and noise pollution.

Bored tunnel construction

The bored tunnel construction

technique has been used at many places in the metro corridor tunnels. The

internal diameter of such tunnels is about 5.6 m and they are generally lined

with precast reinforced concrete segments. Tunnel boring machines (TBMs) have

been used in place of conventional tunnelling methods that employing various

hand mining techniques, since conventional tunnelling methods suffer from major

handicaps with regard to slower progress and risks to existing structures in

the vicinity of tunnel excavation.

Since the bored tunnel

construction for the Delhi metro involved tunnelling through both quartzite and

soft ground, two types of TBMs have been used, namely, rock TBM for rocky

ground and earth pressure balance machine (EPBM) for soft ground. In the case

of an EPBM, the excavated face is supported by pressurizing the soil that has

been dug up, together with additives if necessary, to give it a plastic

texture. A screw auger is used to remove the excavated material. The earth

pressure within the cutter head is maintained by balancing the rate at which it

advances with the rate at which the spoil material is removed and adjusting the

parameters as required. The gap between the excavation surface and the precast

concrete lining is filled by means of an automatic injection from the tail of

the machine, which minimizes ground settlement. Watertightness at the tail is

ensured by injecting grease into the three rows of brush seals.

4 Underground Versus Elevated Alignment

Underground construction is a

much costlier option than elevated alignment. The current average cost per

route kilometre for construction on an elevated alignment, including stations,

rolling stock, signalling, and electrical equipment as well as land and incidental

works, is Rs 1000 million as compared to Rs 3000 million for underground

construction. On account of the vast cost difference, the choice of underground

construction is restricted to areas where elevated alignment is not suitable.

In the case of Delhi metro, underground construction is restricted to the core

area of Delhi on the North-South and East-West corridors, which intersect in

the Connaught Place area. Most of the route length outside the core area is

likely to be constructed as an elevated route.

In the case of elevated segments

of the MRTS, the alignment on city roads usually follows the central verge of

the road. Piers of about 2 m diameter are spaced 20-30 m apart along the

central verge. The arrangement of girders above the pier cap is shown in the

general arrangement given in Fig. 29.5. Tracks are generally laid 8.5-9.5 m

above the road level on elevated routes outside the station. The desirable

minimum width of the roads for locating an elevated MRTS on the same is 30 m,

although a road width of 40-45 m is preferable. The geometry of the road should

be favourable for the adoption of curves adhering to the minimum MRTS

standards. In the case of underground construction on stretches outside the

station, the rail level lies at a minimum depth of 9 m below the road surface.

This is done with the object of 2-3 m of space below the road for electrical

cables, telephone cables, and drains.

A corridor need not be wholly

underground or elevated. An underground corridor in the core city area could

get converted into an elevated corridor in the outer parts, where the

conditions are favourable for such constructions. It is crucial that an extra

stretch of aligned road surface be available between the point where the

underground section ends and the elevated section starts. The alignment in this

stretch should rise from about 9 m below the ground to 9 m above the road

level. In order to ensure that the length of the at-grade stretch is not unduly

long, the tracks are provided with a steep gradient for negotiating this

difference in the level. This stretch can measure 400-500 m in length depending

on the site characteristics.

In the at-grade stretch, the MRTS

tracks are walled on both sides, their outer faces being nearly 10 m apart.

This implies that the road width is effectively reduced by about 11 m on this

stretch. This factor is of great importance in choosing the location for an

at-grade ramp.

Schedule of dimensions

The Delhi Metro Rail Corporation

has drawn up a schedule of the dimensions for its system. These dimensions

should normally be adhered to when undertaking new works and finding

alternatives to existing works on BG lines (1676 mm), except in exceptional

cases where the sanction of the commissioner of railway safety has to be

specifically obtained.

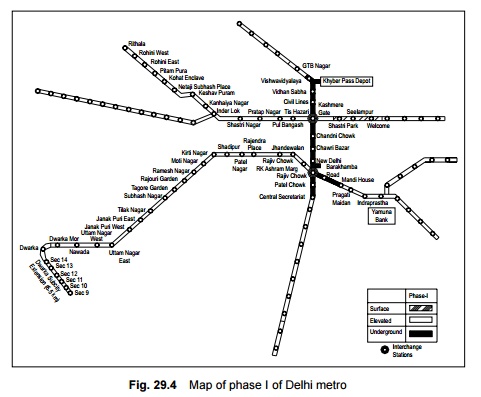

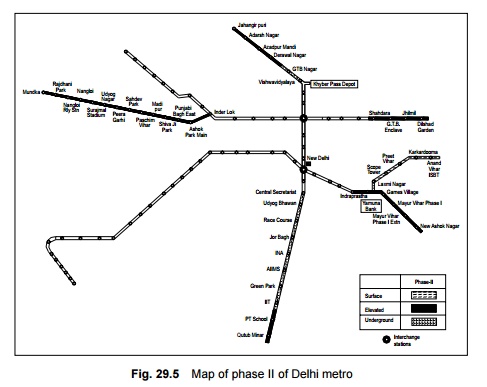

5 Delhi Metro Phase II

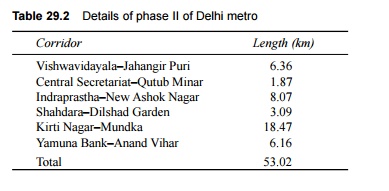

The Delhi Metro Rail Corporation

has already made plans for phase II of Delhi metro (Fig. 29.5). The total route

length is about 54 km as per the details given in Table 29.2.

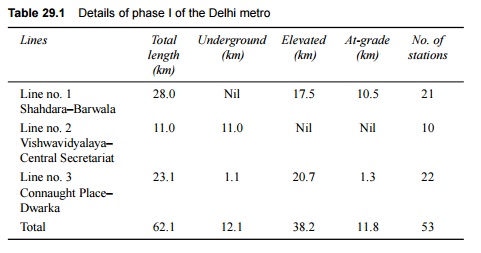

Table 29.2 Details of phase II of

Delhi metro

The preparation of detailed

project reports for the corridors of phase II of the Delhi metro is complete

and the Government of Delhi has already made budgetary provisions for the same.

Work on phase II is scheduled to be completed before 2010.

With the success of the Delhi

metro, several state governments have approached the DMRC for preparing

detailed project reports for metros for their cities. Such reports have already

been prepared for Bangalore and Hyderabad and submitted to the Karnataka and

Andhra Pradesh state governments, respectively. Investigations/ studies are

presently underway for the preparation of detailed project reports for

constructing metro rail systems in Mumbai, Ahmedabad, Kolkata, and Kochi.

Related Topics