Chapter: Electrical machines : DC Generators

Commutation and Interpoles

Commutation

And Interpoles

In larger

machines the commutation process would involve too much sparking, which causes

brush wear, noxious gases (ozone) that promote corrosion, etc. In these cases

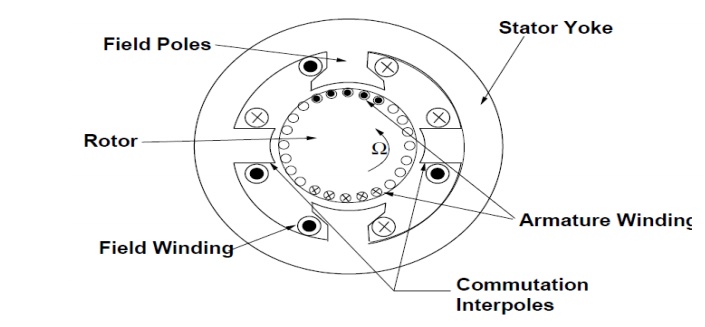

it is common to use separate commutation interpoles. These are separate,

usually narrow or seemingly vestigal pole pieces which carry armature current.

They are arranged in such a way that the flux from the interpole drives current

in the commutated coil in the proper direction

Remember

that the coil being commutated is located physically between the active poles

and the interpole is therefore in the right spot to influence commutation. The

interpole is wound with armature current (it is in series with the main

brushes). It is easy to see that the interpole must have a flux density

proportional to the current to be commutated. Since the speed with which the

coil must be commutated is proportional to rotational velocity and so is the

voltage induced by the interpole, if the right numbers of turns are put around

the interpole, commutation can be made to be quite accurate.

Related Topics