Chapter: Aquaculture Engineering : Feeding Systems

Central feeding system - feeding equipment in Aquaculture

Feeding systems

The term feeding system refers to a complete system that takes the feed directly from the feed silo or hopper, transports it to the fish production unit, and at the end distributes it to the fish. A complete feeding system may comprise three parts: a storage unit, a transport unit and a feed distribution unit. Today feeding systems can be divided into two types:

1. Systems where the feeder is centrally placed and feed is transported to the single fish production units (tanks, ponds or cages) through pipes, normally known as feeding systems.

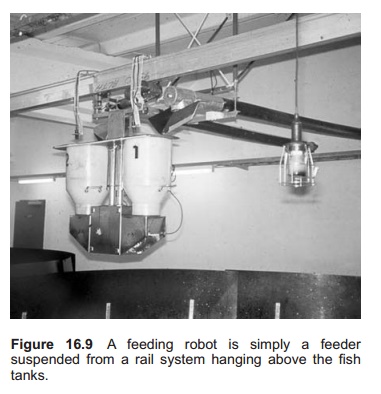

2. Systems where the feeder is installed on a rail system that covers several units, normally called feeding robots.

Central feeding system

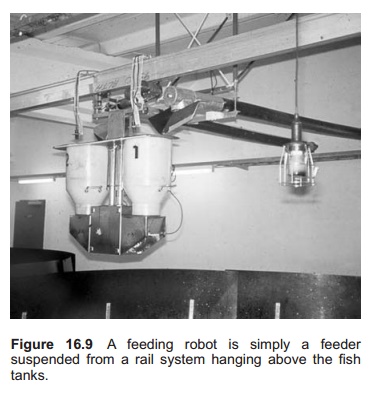

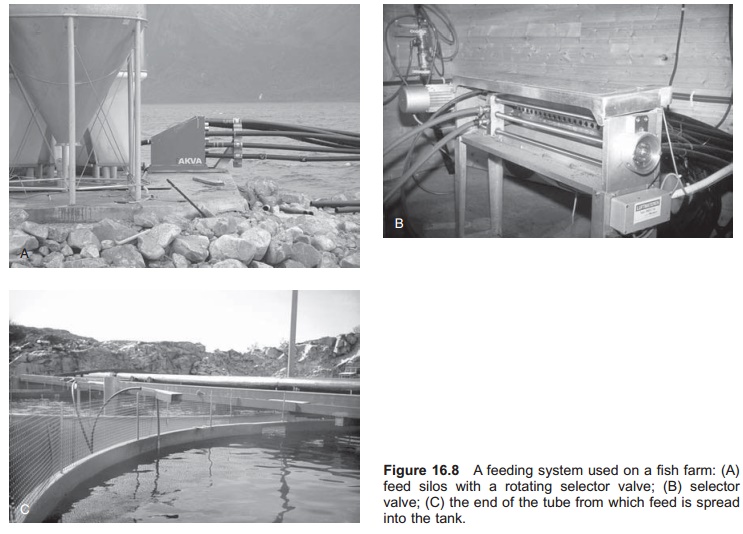

A central feeding system consists of storage silos, a sluice valve, tubes with a flow of water or air for transporting of feed, a selector valve, and eventu-ally a distribution unit (Fig. 16.8).

In this system the feed is delivered from the silo and into an auger that brings the feed particles into a hopper placed above a sluice valve. The sluice valve brings the feed particles from the hopper and into the pipes for further transport to the tanks or cages. To transport the feed particles, water or air is used as a medium and the sluice valve therefore also provides an air or water lock between the hopper and the transport medium; the sluice valve also represents the feed distribution unit.

Whether air or water is used as a transport medium, the velocity in the tubes is such that the feed particles will always stay in suspension. A blower or a pump ensures adequate velocity inside the tubes. During the past few years, air has become the major transport medium. After being trans-ported for a short distance in the pipes (some metres) the feed enters the selector valve whitch determines the production unit to which the feed portion is sent. There are several designs of selector valve; normally a rotating or a horizontal moving selector is used.

After the selector valve the feed is transported to the production unit through the tubes. In sea cages the tubes may be up to several hundred metres in length. The silos and selector valve may be placed on-shore or on a barge. If the system is for large cages, a unit for spreading the feed may also be included.

Correct design and use of the feeding system is important to avoid feed breakage and dust production. Important factors are air temperature, pick-up velocity, material in the pipes, design and use of the selector valve and pipeline routings.

A centrally placed computer controls this type of feeding system. The amount of feed to the different units can be set as fixed or be created automatically. Addition of the initial weight, water temperature, expected growth and mortality in to the computation ensures correct feeding. The computer also stores the inputs and is an important tool for production planning and production control.

Central feeding systems are also available for automatic feeding of moist feed.

Feeding robots

Put simply, a feeding robot is a feeder suspended from a rail system hanging above the fish tanks (Fig. 16.9). A motor to push the feeder along the rail system is included. The rail system is laid over the production units and under the feed silos. The robot may have its docking station under the silos where it enters for automatic refilling with feed when the hopper on the feeder is empty. When the robot is feeding it moves along the rail until it hits a chip attached to the rail over each tank. Based on information in this chip, the feeder (robot) recognizes the tank. On the robot there is a computer where the amount to be fed to the actual tank is programed. When the robot hits the chip it will there-fore feed the programed amount of feed to the tank. After this it continues to the next tank, and so on. When the hopper on the robot is empty it auto-matically goes back to the silos for refilling. Several individual feeders can be attached to the same robot, so that it can deliver several feed sizes in the same operation. The electricity supply to the feeder and the motor may be an integrated part of the rail system, or it can be a battery which is recharged in the docking station. The great advantage with this system is that the same feeding mechanism can be used for feeding of several tanks. In this way more investment in this unit means it can be designed to feed more accurately. Accuracy can be improved by using double dispensers (multistage), as is in some robots.

Related Topics