Chapter: Civil : Highway Planning and Alignment : Highway Construction Materials And Practice

California Bearing Ratio Test

California Bearing Ratio Test

California

Bearing Ratio (CBR) test

was developed by

the California Division of

Highway as a method of classifying and evaluating soil-sub grade and base course

materials for flexible pavements. CBR test, an empirical test, has been used to

determine the material properties for pavement design. Empirical tests measure

the strength of the material and are not a true representation of the resilient

modulus. It is a

penetration test wherein a standard piston, having

an area of 3 in2 (or 50 mm diameter), is used to penetrate the soil

at a standard rate of 1.25 mm/minute. The pressure up to a penetration of 12.5

mm and it's ratio to the bearing value of a standard crushed rock is termed as

the CBR.

In most cases, CBR decreases as the

penetration increases. The ratio at 2.5 mm penetration is used as the CBR. In

some case, the ratio at 5 mm may be greater than that at 2.5 mm. If this

occurs, the ratio at 5 mm should be used. The CBR is a measure of resistance of

a material to penetration of standard plunger under controlled density and

moisture conditions. The test procedure should be strictly adhered if high

degree of reproducibility is desired. The CBR test may be conducted in

re-moulded or undisturbed specimen in the laboratory. The test is simple and has

been extensively investigated for field correlations of flexible pavement

thickness requirement.

Test Procedure

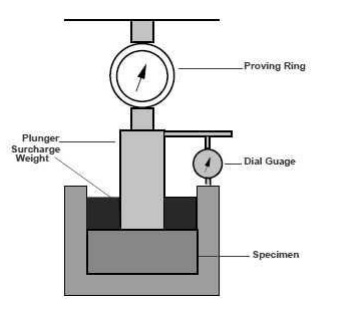

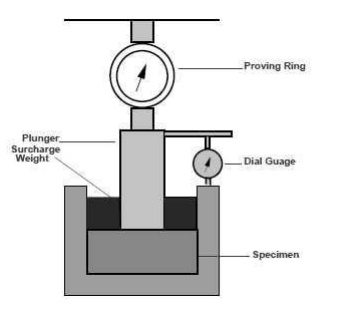

The laboratory CBR apparatus consists of a mould 150

mm diameter with a base plate and a collar, a loading frame and dial gauges for

measuring the penetration values and the expansion on soaking.

The specimen in the mould is soaked in water for

four days and the swelling and water absorption values are noted. The surcharge

weight is placed on the top of the specimen in the mould and the assembly is

placed under the plunger of the loading frame.

Load

is applied on the sample by a standard plunger with dia of 50 mm at the rate of

1.25 mm/min. A load penetration curve is drawn. The

load values on standard crushed stones are 1370 kg and 2055 kg at 2.5 mm and

5.0 mm penetrations respectively.

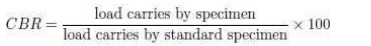

CBR

value is expressed as a percentage of the actual load causing the penetrations

of 2.5 mm or 5.0 mm to the standard loads mentioned above. Therefore,

Two values of CBR will be obtained. If the value of

2.5 mm is greater than that of 5.0 mm penetration, the former is adopted. If

the CBR value obtained from test at

5.0 mm penetration is higher than that at 2.5 mm,

then the test is to be repeated for checking. If the check test again gives

similar results, then higher value obtained at

5.0

mm penetration is reported as the CBR value. The average CBR value of three

test specimens is reported as the CBR value of the sample.

Related Topics