Chapter: Civil : Design of Reinforced Concrete Elements : Methods Of Design Of Concrete Structures

Working Stress Method Design

WORKING STRESS METHOD DESIGN

GENERAL

PRINCIPLES OF WORKING STRESS DESIGN

(a)

General features

During the early part of 20th century,

elastic theory of reinforced concrete sections outlined was developed which

formed the basis of the working stress or permissible stress method of design

of reinforced concrete members. In this method, the working or permissible

stress in concrete and steel are obtained applying appropriate partial safety

factors to the characteristics strength of the materials. The permissible

stresses in concrete and steel are well within the linear elastic range of the

materials.

The design based on the working stress method

although ensures safety of the structures at working or services loads, it does

not provide a realistic estimate of the ultimate or collapse load of the

structure in contrast to the limit state method of design. The working stress

method of design results in comparatively larger and conservative sections of

the structural elements with higher quantities of steel reinforcement which

results in conservative and costly design. Structural engineers have used this

method extensively during the 20th

century and presently the method is incorporated as an alternative to the limit

state method in Annexure -B of the recently revised Indian Standard Code Is :

456 -2000 for specific applications.

The permissible stresses in concrete under service

loads for the various stress states of compressive, flexure and bond is

compiled in Table 2.1 (Table 21 of IS ; 456 -2000)

The

permissible stress in different types of steel reinforcement is shown in table

2.2 (Table 22 of IS 456

-2000)

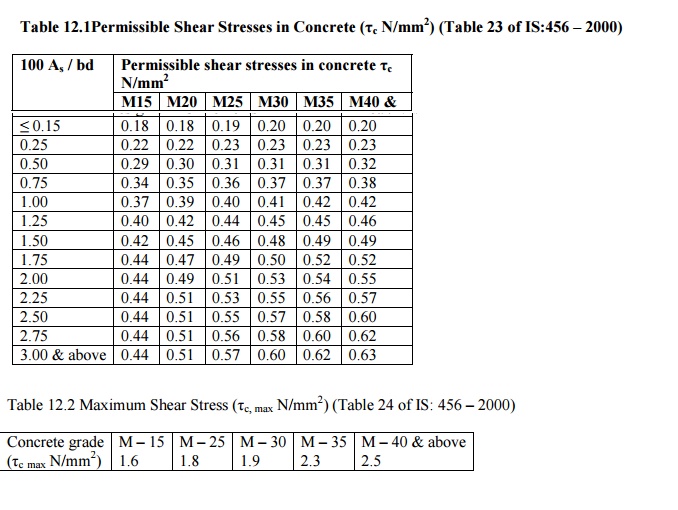

The permissible shear stress for various grades of

concrete in beams is shown in Table 12.1 (Table 23 of IS: 456 -2000)

The maximum shear stress permissible in concrete for

different grades is shown in Table 12.2 Table 12.2 (Table 24 of IS: 456 -2000)

In

the case of reinforced concrete slabs, the permissible shear stress in concrete

is obtained by multiplying the values given in Table 2.1 by as shown in Table

12.3 (Section 40.2.1.1. of IS; 456 -2000)

Note: As

is that area of longitudinal tension reinforcement which continues at least

one effective depth beyond the section being considered except at

supports where the full area of tension reinforcement may be used provided the

detailing conforms to 26.2.3.

The maximum shear stress permissible in concrete for

different grades is shown in Table 12.2 (Table 24 of IS 456 -2000)

In the case of reinforced concrete slabs, the

permissible shear stress in concrete is obtained by multiplying the3 values in

Table 2.1 by a fac shown in Table 12.3 (Section 40.2.1.1. of IS 456 -2000)

(b) General

design procedure

In the working stress design, the cross -sectional

dimensions are assumed based on the basic span / depth ratios outlined in

Chapter 5 (Table 5.1 and 5.2) (Section 23.2.1. of IS: 456 -2000)

The working load moments and shear forces are

evaluated at critical sections and the required effective depth is checked by

using the relation:

d = ?

M / Q.b

Where d = effective depth of section M =

working load moment b = width of section

Q = a constant depending upon the

working stresses in concrete and steel, neutral axis depth factor (k) and lever

arm coefficient (f).

For different grades of concretepiledin

Tableand2.3. steelThedepth th provided should be equal to or greater than the

depth computed by the relation and the area of reinforcement required in the

section to resi

The number of steel

bars required is selected with due regard to the spacing of bars and cover

requirements.

After complying with

flexure, the section is generally checked for resistance against shear forces

by calculating thec givennominal=(Vby/bd)shear? stress ?

Where V = Working shear force at critical section.

The permissible shearc)depends

uponstressthepercentagereinforcementsconcreteinthecross -(? section and grade

of concrete as shown in Table 12.1

Ifc< ?vsuitable? shear

reinforcements are designed in beams at a spacing sv given by the

relation;

Sv

= [ 0.87 fy Asv d / Vus]

Where sv = spacing of stirrups

Asv

= cross -sectional area of stirrups legs

fy

= Characteristics strength of stirrup reinforcement

d

= effective depth

Vs

= [ V -?c.b .d]

Ifv< ?c,

nominal? shear reinforcements are provided in beams are provided in beams at a

spacing given by

Sv

[ 0.87 fy Ast /

0.4 b]

In case of slabs, the

permissible shear stres Also in the case of slabsv)shouldnot

excetheed nominalhalfthecmaxsheshownvalueinrs

Table 12.2. In such cases the thickness of the slab

is increased and the slab is redesigned.

In the case of compression

members, the axial load permissible on a short column reinforced with

longitudinal bars and lateral ties is given by

P =cc A(?c+sc

?Asc)

Where scc = permissible stress in

concrete in direct compression (Refer Table 2.1)

Ac

= cross -sectional area of concrete excluding the area of reinforcements.

Ssc

= permissible compressive stress in reinforcement

Asc = cross -sectional area

of longitudinal steel bars.

Related Topics