Chapter: Total Quality Management : Introduction

Total Quality Management

TOTAL QUALITY MANAGEMENT

INTRODUCTION

TOTAL = Made up of the whole

QUALITY = Degree of excellence a product or

service provides

MANAGEMENT = Act, art or science /manner of handling, controlling, directing etc

Meaning

TQM is a structured system for

satisfying internal and external customers and suppliers by integrating the

business environment, continuous improvement and breakthrough with development,

improvement and maintenance cycles while changing organizational culture.

What Is Quality

Quality

basically defines what is required, and how it can be achieved. It also implies

complying with the necessities, and suitability of being used. The realm of

quality has been changing rapidly from just manufacture, to numerous other

disciplines like finance, information technology, and human resources. The

benefits of implementing a quality management system are numerous, including

creation of quality products, and quality systems. Quality management system

software is extremely useful for implementing a quality management system, and

excellent quality control, resulting into total quality management. Software

testing procedures are used extensively, to ensure that only the quality

products are produced, while those not meeting the quality standards are

rejected.

What Is A Quality Management System

A quality

management system can be defined as the implementation of dedicated activities

in a project to obtain continuous improvement, and enhance the organization

efficiency. The foremost effort of this system is to correctly and precisely

define the procedure that will cause creation of quality products and quality

services. The aim is to prevent the errors while within the project, and not

after a product has been delivered to the user. There are many benefits to a

quality management system, due to which the organizations are devoting more

efforts to improve quality management.

Benefits of Quality Management Systems

The trend

of implementing a quality management procedure is gaining popularity in all

organizations, since there are tremendous benefits in using a quality

management system. Some of the benefits are explained below:

Achievement Of Project

Scope

This

system facilitates a business, to attain the objectives that have been defined

in the organization strategy. It ensures the achievement of stability and

reliability regarding the techniques, equipment, and resources being used in a

project. All project activities are integrated and aligned towards the

achievement of quality products. These efforts commence by identifying the

customer needs and expectations, and culminate in their contentment.

Customer Satisfaction

A fully

recognized and implemented quality management system, will ensure that the

customer is satisfied by meeting their requirements, and will thus enhance the

confidence of the customer. Attaining customer satisfaction is a great

achievement for the organization, that will assist in capturing the market, or

increase the market share.

Consistent Products

Implementing

a quality management system can assist to attain more consistency in the

project activities, and enhance the effectiveness by improvement in the

resources and time usage.

Implementation Of Best Practices & Process

Improvement

The discipline of quality includes the efforts directed towards the improvement of processes, being used to maintain consistency, reduce expenditures, and ensure production within the schedule baseline. The systems, products, and processes are continually improved by the implementation of best practices, like modern manufacture techniques, use of primavera project management software including Primavera P6, and the use of proper quality control techniques.

Increase In Production

Improved

production is achieved due to proper evaluation techniques being applied, and

better training of the employees. A strict process control is directed towards

performance consistency, and less scrap. Supervisors experience less late night

problematic phone calls, since the employees are trained on troubleshooting.

Less Rework

Quality

is measured continuously due to the appropriate procedures that ensure

immediate corrective actions on occurrence of defects. Since efforts are

directed towards quality products, rework due to warranty claims is minimized.

This reduction increases customer confidence, and increase in business.

Increased Financial Performance

The

discipline of quality includes the efforts directed towards the improvement of

processes, being used to maintain consistency, reduce expenditures, and ensure

production within the schedule baseline. The systems, products, and processes

are continually improved by the implementation of best practices, like modern

manufacture techniques, use of primavera project management software including

Primavera P6, and the use of proper quality control techniques.

Increase In Market Share

Other

quality management system benefits include proper management of project risks

and costs, and identification of development prospects. This results in an

increase in market share and reputation, and capability to react to industry

opportunities.

Improvement In Internal Communications

The

quality management system emphasizes the issues related to operations

management. This encourages frequent interaction between project departments or

groups, and promotes harmony. All these factors contribute to improved quality,

and customer satisfaction.

Implementation Of Quality

Management System

An

efficient quality management system should initially accurately determine the

expectations and needs of the customers, and subsequently transform this into

quality products. For the successful implementation of a TQM system, it is

essential that the executive management

should provide full support and leadership, provision of a suitable quality

policy, and establishment of measurable goals. The project management team

should be involved in the quality system, and suitable training be arranged to

enhance the skills. A useful system should be a tactical tool that is intended

to facilitate the achievement of project goals. Evaluation of the usefulness,

efficiency, and ability of a quality management system is crucial. Review and

examination should be performed regularly to audit the quality requirements,

achievement of the project objectives, and ensuring customer satisfaction. This

review will ensure that the quality management system benefits are being fully

obtained, and amendments in the system are implemented wherever necessary.

Evolution of Quality Control

DEFINING QUALITY:

Quality

can be quantified as follows Q = P / E

where,

Q =

Quality

P =

Performance

E =

Expectation

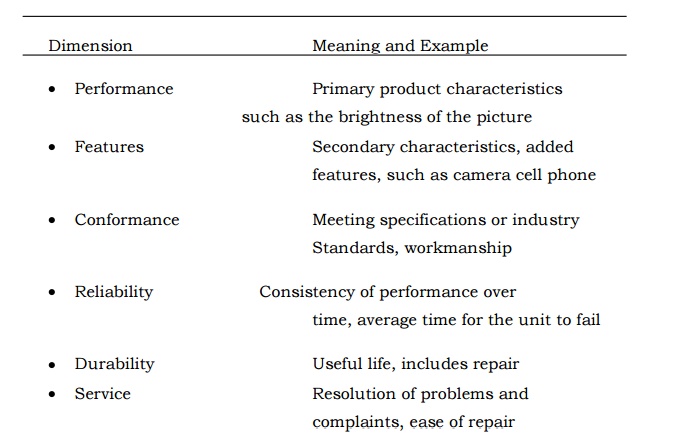

THE

DIMENSION OF QUALITY

IMPORTANT POINTS TO BE NOTED WHILE QUALITY PLANNING

:

1. Business,

having larger market share and better quality, earn returns much higher than

their competitors.

2. Quality

and Market share each has a strong separate relationship to profitably.

3. Planning

for product quality must be based on meeting customer needs, not just meeting

product specifications.

4. For same

products. We need to plan for perfection. For other products, we need to plan

for value.

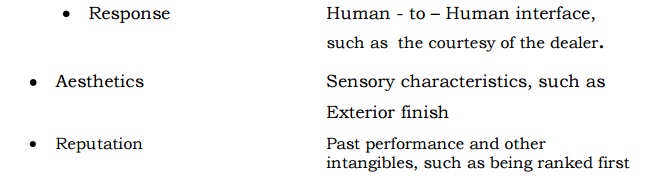

BASIC

CONCEPT OF TQM

1. A

committed and involved management to provide ling term, top to bottom

organizational support.

It is useless to embark on a

quality journey without the top management‘s commitment to quality. Top

management must participate in the quality programme. They must also

participate on quality improvement teams and also act as coaches to other teams

2. An un – wavering focus on the customer both internally

and externally. The employees of the organization in

the first place. Mangers must listen to the suggestions and recommendations

made by the employees to improve quality.

This aspect of listening to the

voice of customers leads to the emphasis of design quality and defect the prevention.

3. Effective involvement and utilization of entire

workforce.

TQM is everyone‘s responsibility

in an organization. All workers in and organization must be oriented towards

TQM and all personnel must be trained in TQM, statistical process control and

other appropriate quality improvement skills.

4. Continuous improvement of the business and production

process.

Continuous improvement refers to

constant refinement and improvement of products, services and organizational

systems to yield improved value to consumers.

Areas such as on-time delivery,

scrap reduction, supplier management, customer satisfaction, etc. are good

quality projects to begin continuous improvement.

5. Treating suppliers as partner

The traditional relationship

between the buyer and the supplier has been adversarial in nature. Each tried

to extract the maximum out of each other. There was lack of trust on each

other.

To ensure good relationship with

suppliers, frequent change of suppliers should be avoided and suppliers should

be few in number so that true partnering can occur.

6. Establishing performance measures for the process.

Performance measure is an integral

part of the quality process. If an organization cannot measure its progress, it

is useless for it to go on a quality journey. Performance measures such as

percentage of non conformance, absenteeism, customer satisfaction, etc., should

be determined for each functional area.

Definition for TQM

Total Quality Management (TQM) is a comprehensive and structured

approach to organizational management

that seeks to improve the quality of products and services through ongoing

refinements in response to continuous feedback.

HISTORICAL

REVIEW

Ø The concept of specification of

labour was introduced during the industrial revolution

Ø As a result a worker no longer

made the entire product, only a portion. This change brought about a decline in

workmanship

Ø Because productivity increased

there was a decrease in cost, which result in lower customer expectations

Ø As products become more

complicated and jobs more specialized, it became necessary to inspect product

after manufacturing

Ø In 1942 W.A. Shewhart of Bell

Telephone Laboratories developed a statistical chart for the control of product

variables. This is beginning of SQC

Ø In some decade H.F. Dodge and H.G.

Romig both of Bell telephone laboratories developed the area of acceptance

sampling as a substitute for 100% inspection. It is recognized by 1942

Ø In 1946 the American society for

Quality Control was formed. Now it is American Society for Quality

Ø In 1950 W. Edwards Deming who

learned SQC from shewhart, gave a series of lectures on statistical methods to

Japanese Engineers

Ø Un 1954 Joseph M. Juran made his

first trip to Japan and further he emphasized management‘s responsibility to

achieve quality

By this concept the Japanese set

the quality standard for the rest of the world In 1960 the first quality

circles were formed for quality improvement by Japanese workers

Ø By 19770‘s and 80‘s U.S. managers

were making frequent trips to Japan to learn about the Japanese miracle

Ø In 1980‘s the automotive industry

began to emphasizes statistical process control (SQC)

Ø Emphasis on quality continued in the auto industry in

the year 1990‘s. when

the Saturn automobile ranked first in customer satisfaction in 1996

Ø ISO 9000 became the world wide

model for quality system

TQM FRAMEWORK

PRINCIPLES

OF TQM

1. Customer focus

2. Leadership

3. Involvement of people

4. Continuous improvement/ long-term

5. Systematic improvement/ approach

6. Problem prevention

7. Quality as everyone‘s job

8. Mutually beneficial

THE DEMING PHILOSOPHY

In 1950 he taught SPC concepts and

the importance of quality to the leading CEO‘s

of Japanese industry. He developed

the following fourteen points as a

theory for management for

improvement of quality productivity and competitive position.

1.Create

and publish the aims and purposes of the organization

Organization must develop a long

term view at least 10 yrs Plan to stay in business by setting long range goals

Resources must be allocated for

research, training and continuing education to achieve the goals

Innovation in promoted to ensure

that the product or services does not become absolute

Organizational philosophy is

developed to send the message that everyone is part of the organization

2.Learn

the new philosophy

Organization must seek

never-ending improvement and refuse to accept non-conformance.

Customer satisfaction is the

number one priority

The organization must concentrate

on defect prevention rather that defect detection.

Everyone should involved in the

quality journey and change his or her attitude about quality

Supplier must help to improve

quality

Share the information relative to

customer expectations

3.Understand

the purpose of inspection

Mass inspection is costly and un

reliable it is replace by statistical techniques It is required for self and

supplier

Mass inspection is managing for

failure and defect prevention is managing for success.

4.Stop

awarding business based on price alone

Awarding business based on the low

bid, because price has no meaning without quality

To examine how customer

expectations are affected and provide feedback to the supplier regarding the

quality

5.Improve

constantly and forever the system

Management must have take more

responsibility for problems by actively finding and correcting problemsSo that

quality and productivity are continually and permanently improved and costs are

reduced.

The focus is preventing problems

before they happen.

Responsibility is assigned to

teams to remove the causes of problems and continually improve the process.

6.Institute

training

Employee must be oriented

Management must allocate resources to train employee to perform their jobs

Everyone should be trained in statistical methods and monitor the need for

further training.

7.Teach

and institute leadership

Improving supervision is

management‘s responsibility Training in statistical methods Supervisors not

focusing on negative fault findings,

He create positive supportive

Communication must be clear from the top management to supervisor and to

operators

8.Drive

out fear, create trust and create a climate for innovation.

By providing workers with adequate

training, good supervision and proper tools to do the job as well as removing

physical dangerous.

When people are treated with

dignity fear can be eliminated and people will work for the general good of the

organization.

This climate will provide ideas

for innovations and improvement.

9.Optimize

the efforts of teams, groups, and staff areas.

Barriers internally like levels of

management among department within department etc. Barriers externally like

with customers and suppliers The barriers exist because of poor communication,

ignorance of the organization mission, completion, fear and personal grudges.

To overcome these attitudes need to be changed communication channel opened,

project teams organized, training for teamwork.

10.Eliminate

exhortations for the work force

Exhortations that ask for

increased productivity without providing specific improvements methods They do

not produce a better product or service, because the workers limited by the

system Improvements in the process cannot be made unless the tools and methods

are available.

11.a)

Eliminate numerical quotas for the work force

Instead of quotas, management must

learn and institute methods for improvements. Quotas and work standards focus

on quality rather that quality. Quotas should be replaced with statistical

method of process control.

b.)

Eliminate management by objectives

Management must learn the

capabilities of the processes and how to improve them Management by numerical

is an attempt to manage without knowledge of what to do

12. Remove barriers that rob people of pride

of workmanship

Loss of pride in workmanship

exists throughout organization because Workers do not know how to relate the

organization mission

They are being blamed for system

problems

Poor designs lead to the production of ―Junk‖

In adequate training is provided

In adequate or in-efficient

equipment is provided for

Performing the required work.

13.

Encourage Education and self-improvement for everyone

What an organization need is

people who are improving with education

A long term commitment to continuously

train and educate people must be made by management

Everyone should be retained as the

organization requirements change to meet the changing environment

14.

Take action to accomplish the transformation

Management has to accept the

primary responsibility for the never ending improvement of the process.

Management must be committed,

involved and accessible if the organization is to succeed in implementing the

new philosophy.

BARRIERS

/ OBSTACLES IN IMPLEMENTATION OF TQM

Lack

of management commitment

The management commitment should

be clearly communicated both verbally and in action to the organization.

If the workers feel that the

management is doing only the talking about no action is initiated on TQM then

they too will lack necessary commitment and motivation to implement TQM

principles.

Inability

to change organizational culture

The past culture should be

unlearned and the new culture should be learnt. This gives rise to enormous

resistance to change from the employees.

It is very difficult for an

organization to make a culture change.

Improper

planning

When planning for TQM all the

constitutes should be involved in the development of the implementation plan

and any modification that occur as the plan evolves. Rapid planning will ensure

that the TQM fails.

Planning should be done on the

customer front, employee‘s front and the supplier front.

Lack

of continuous training and education

Training and education is an

ongoing process for everyone in the organization. The training needs of the

employees must be determined and a plan should be developed to satisfy those

needs.

Training and education are most

effective when senior management conducts the training programme based on the

principles of TQM

Incompatible

organizational structures and isolated individuals and department

Lack of co ordination and

difference of opinion among departments and individuals in an organization will

create implementation problems.

The use of multifunctional teams

can help to break this barrier.

Restructuring of the organization

may be needed to make the organization more responsive to the needs of the

customers.

Ineffective

measurement techniques and lack of access to data and results

In order to improve the process,

one has to measure the present position. Mechanisms to measure the present

position should be available in the organization.

Once the measurement is done the

data should be made available to the necessary mangers to make decisions.

Any clogging of data to the

managers will become a barrier to TQM implementation.

Playing

inadequate attention to internal and external customers

Organizations

have to understand the changing needs and expectations of the customers both

internal and external.

Effective feedback mechanisms that

provide data for decision making are necessary for this understanding.

One way to overcome this is to

give the right people in the organization, a direct access to the customers.

Inadequate

use of empowerment and teamwork

Individuals should be empowered to

make decisions and take responsibility to make decisions that affect the

efficiency of the process of production.

Teams should be formed and need to

have proper training. The team‘s recommendations should be adopted whenever

possible.

CONTRIBUTIONS

OF JURAN‟S :

1. Identify customers

2. Determine customer needs

3. Translate

4. Establishment units of measurement

5. Establish measurements

6. Develop product

7. Optimize product design

8. Develop process

9. Optimize process capability

10.

Transfer

CONTRIBUTIONS

OF CROSBY‟S :

1. Management commitment

2. Quality improvement team

3. Quality measurement

4. Cost of quality evaluation

5. Quality awareness

6. Corrective action

7. Zero defect program

8. Supervisor training

9. Zero defects day

10.

Goal

setting

11.

Error

cause removal

12.

Recognition

13.

Quality

councils

14.

Do

it over again

Related Topics