Chapter: Aquaculture Engineering : Egg Storage and Hatching Equipment

Systems where the Fish eggs lie on the bottom - Aquaculture

Systems where the eggs lie on the bottom

There is much experience concerning eggs lying on the bottom and several systems have been developed for intensive fish farming, especially for use in salmonid farming. It is possible to divide these into three different systems:

System where the eggs remain in the same unit for the whole process from spawning up to fry ready for first feeding

System where the eggs lie in thick layers and must be moved before hatching System where storage, hatching and first feeding are carried out in the same unit.

The system chosen depends on the management strategy for the hatchery, whether the farm produces eggs for its own use or for sale. If the farm is to produce eggs for sale they may lie in thick layers, because these will be sold before hatching. This system is suitable for salmonid eggs that are sold as eyed eggs, because they tolerate a lot of handling.

Systems where the eggs lie in the same unit from spawning to fry ready for start feeding

Hatching troughs

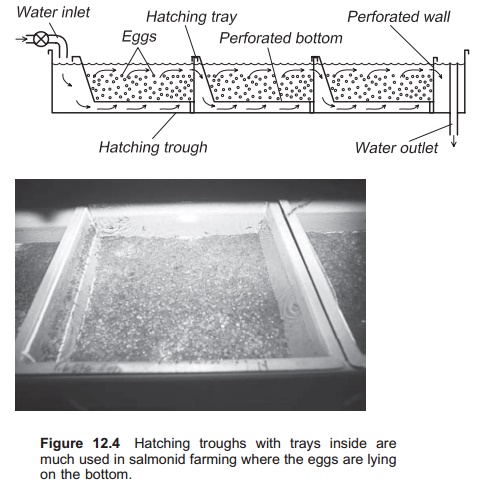

A common unit is the hatching trough with trays inside; this is also known as the California system (Fig. 12.4). Trays or boxes are placed beside each other lengthwise, in the trough. The trays have a perforated bottom and one of the sidewalls is also perforated. Water is supplied at one end of the trough and leaves from the opposite end. A level outlet controls the water level in the trough.

Inside the trough the tray is installed so that an undercurrent of water is forced to flow up through the perforated bottom, through the layers of eggs lying in the tray and then out through the perforated side of the tray. The water is then forced down to the bottom of the trough and up through the perforated bottom of the next tray. In this way an undercurrent is generated in all the trays in the trough.

After hatching there are large amounts of eggshells to be removed to prevent obstruction of the outlet grating. To increase the grating area an L-shaped outlet grating can be installed in the tray during hatching.

The typical size of one type of hatching tray is 40 cm × 40 cm × 15 cm. In each trough there may be 4–7 trays. The number of eggs in each tray is species dependent; normally 1–2 l or two layers of eggs is recommended for salmon. The recommended water flow to each trough is 7 l/min and 12 l/min, for troughs with four and seven trays, respectively. If the water supply is too large, the undercurrent may lift the eggs in the trays; increased mortality may occur if the eggs are moved during critical phases in the incubation period. The troughs and trays are usually made of glass-reinforced plastic.

There are also simpler hatching troughs where the eggs are not distributed in individual trays, but placed along the whole surface of the trough. The water enters on one side and leaves from the opposite side. Such a system has no up-flowing water through the egg layers, but a horizontal flow. The capacity per area unit is therefore lower. In addition, the hatching results are normally reduced, and the work requirement for production is increased.

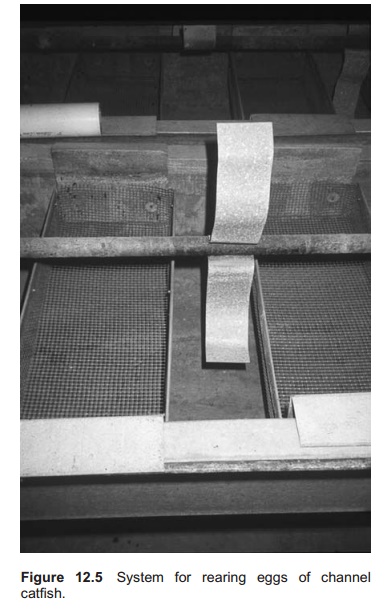

A special type of hatching trough, or small raceway, can be used in channel catfish production. Here the eggs are put into stiff cloth baskets.

Between each basket there is a space where a small paddle wheel rotates (Fig. 12.5) to simulate the fanning action of the adult male. As catfish eggs are deposited in an adhesive yellow mass, it may need to be broken into smaller pieces before being placed in the baskets.

Artificial substrate

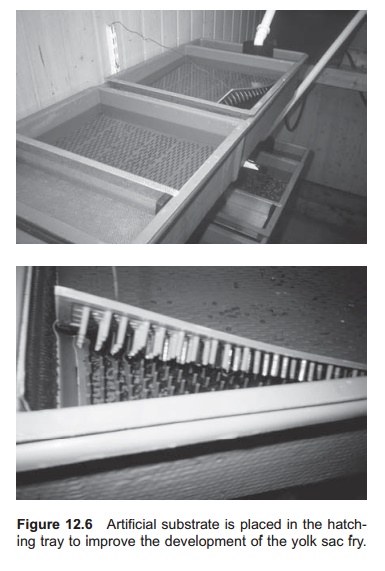

Artificial substrate can be placed in the bottom of the trays to improve the results (Fig. 12.6). The eggs are laid on top of a perforated plate in the hatch-ing trough, and when hatching occurs the yolk sac fry (alevins) will move down through the perforations. The artificial hatching substrate is located below the perforated plate. This substrate creates small spaces where the yolk sac fry can stay in an upright position. In this way only a small percent-age of the yolk sac is used for swimming and maintaining balance. Instead this energy is used for growth. The substrate can be designed in many ways, from squared cells to mats made of artificial grass (for example, AstroTurfTM). The mats are usually made of plastic. Increased growth and reduced mortality have been achieved for salmonids with the use of artificial substrate. It is

Hatching cabinet

In the hatching cabinet the eggs are placed in drawers or on racks (low boxes) on top of each other. There are two different designs of hatching cabinet, either water drops fall from the top, or there is an individual water inlet and outlet in each drawer (Fig. 12.7).

The second design is the most used; the construction includes an individual inlet and outlet to each drawer, with the outlet keeping the water level constant. The drawer has a perforated bottom where the water flows up through the layers of eggs.

After passing through one drawer the water is sent into the drawer below. This system has the advantage that it maximizes the space utilization in relation to hatching trough and trays, but it is more difficult to control and reduced production may result.

Systems using the first design comprise a number of drawers made of perforated plates where the eggs are distributed. Water is supplied from the top and flows down through the layers. However, the eggs must be removed before hatching in this system.

Systems where the eggs must be removed before hatching

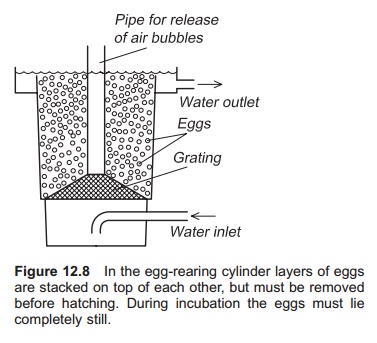

In egg-rearing cylinders the eggs are layered on top of each other (Fig. 12.8), so this system cannot be used through to hatching, and for salmonids only to

the eyed egg stage. In these cylinders the water is taken in at the bottom and a distribution plate ensures that it is distributed evenly through the layers of eggs via an underflow. The water will then flow up through the layers of eggs and over the top edge of the cylinder to the outlet. To avoid air bubbles or clogging, the distribution plate must be set at an angle and there is an aeration pipe in the centre of the cylinder. From here air bubbles can go to the surface without passing through the layers of eggs in the cylinder. If the air bubbles must pass through the egg layers they may increase mortality by moving the eggs during a critical phase of development.

A commonly used egg-rearing cylinder contains approximately 30 l of eggs; the necessary water supply is 5–7 l/min. The great advantage of using these cylinders is that more eggs can be stored in a restricted area; up to 120 l/m2 floor area. The cylinders are often made of polyethylene (PE); typically 80 cm high and 50 cm diameter. Larger tanks of up to 200 l, may also be used with an up-flow of water, but here control of conditions is reduced.

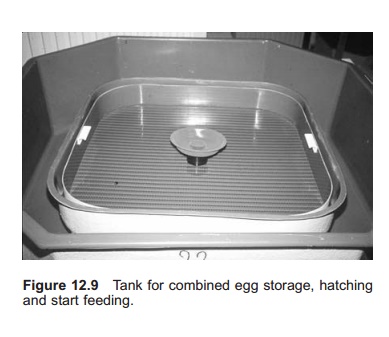

System where storing, hatching and firs feeding are carried out in the same unit

There is also special hatching equipment that may be placed directly into the first feeding units (Fig. 12.9). The space, water supply and water outlet to the first feeding units can then also be used for storing and hatching of the eggs. In one arrangement the hatching installation consists of a perforated inner bottom and a fixed exterior bottom where the hatching substrate can be attached. It is placed inside the tank on legs and a special larvae outlet is directed into the tank outlet. The advantage with this system is that the same unit is used for egg storage, hatching and first feeding. Therefore less space is needed and no separate hatchery is necessary. Problems with disease, due to the lack of a special isolated area, can be a disadvantage with the system; neither is it as suitable for firstspecialized egg production. The system is most commonly used in smaller farms.

Related Topics