Chapter: Civil : Strength of Materials : Advanced Topics In Bending of Beams

Strength of Materials- Advanced Topics In Bending of Beams

ADVANCED TOPICS IN BENDING OF BEAMS

1 UNSYMMETRICAL BENDING

The plane of loading

(or) that of bending does not lie in (or) a plane that contains the principle centroidal axis of the cross-

section; the bending is called Unsymmetrical bending.

2 STATE THE TWO REASONS

FOR UNSYMMETRICAL BENDING

(i) The section is symmetrical (viz. Rectangular,

circular, I section) but the load line

is inclined to both the principal axes.

(ii) The section is unsymmetrical (viz. Angle

section (or) channel section vertical

web) and the load line is along any centroidal axes.

3.SHEAR CENTRE

The shear centre (for any transverse section

of the beam) is the point of

intersection of the bending axis and the plane of the transverse

section. Shear centre is also known as

'centre of twist'

4.WRITE THE SHEAR CENTRE EQUATION FOR CHANNEL

SECTION

e = Distance of the shear centre (SC ) from the web along the symmetric axis XX

Aw

= Area of the web

Af

= Area of the flange

A

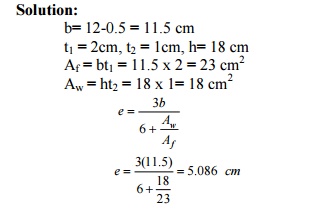

CHANNEL SECTION HAS FLANGES 12 CM X 2 CM AND WEB 16 CM X 1 CM. DETERMINE THE SHEAR CENTRE OF THE CHANNEL

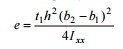

5 WRITE THE SHEAR CENTRE EQUATION FOR

UNSYMMETRICAL I SECTION

e = Distance of the shear centre (SC) from the

web along the symmetric axis XX t1

= thickness of the flange

h = height of

the web

b1

= width of the flange in right portion.

b2

= width of the flange in left portion.

Ixx

= M.O.I of the section about XX axis.

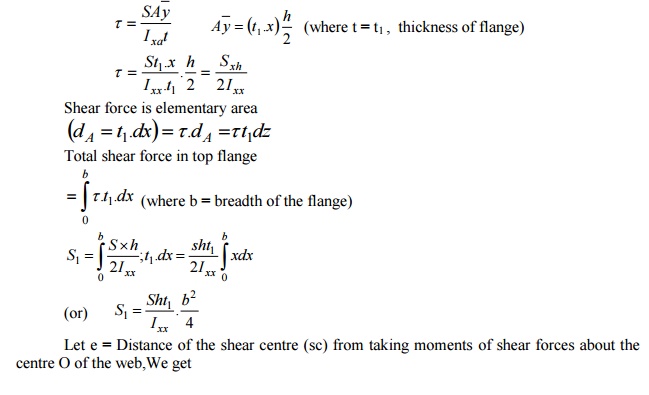

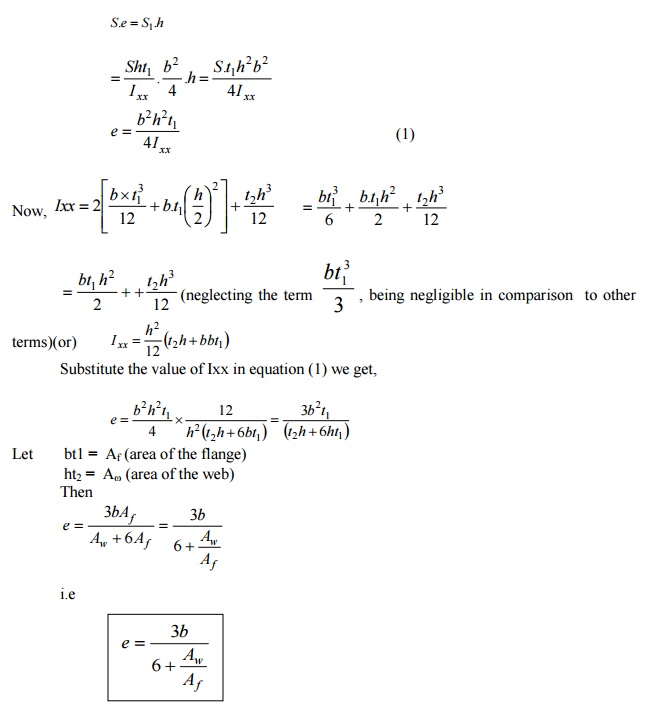

6 DERIVE THE EQUATION OF SHEAR CENTRE

FOR CHANNEL SECTION

A

channel

section (flanges: b x t1 ;

Web h x t2) with XX as the

horizontal symmetric axis.

Let S =

Applied shear force. (Vertical downward X)

(Then S is

the shear force in the web in the upward direction)

S1 = Shear force in the top flange

(there will be equal and opposite shear force

in the bottom flange as shown.)

Now, shear

stress (t) in the flange at a distance of x

from the right hand edge (of the top flange)

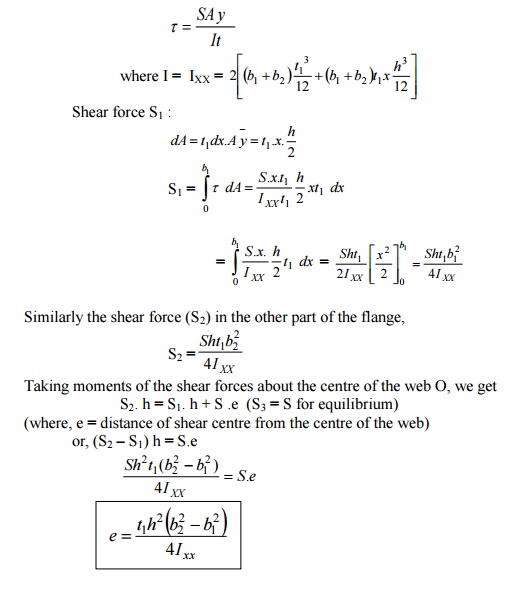

7 DERIVE THE EQUATION OF SHEAR CENTER

FOR UNEQUAL-SECTION Solution:

An unequal I -section which is symmetrical about XX axis.

Shear stress in any layer,

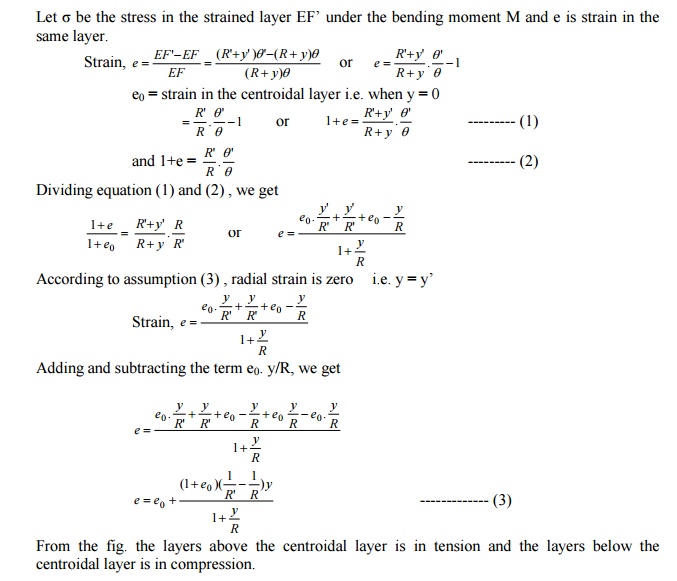

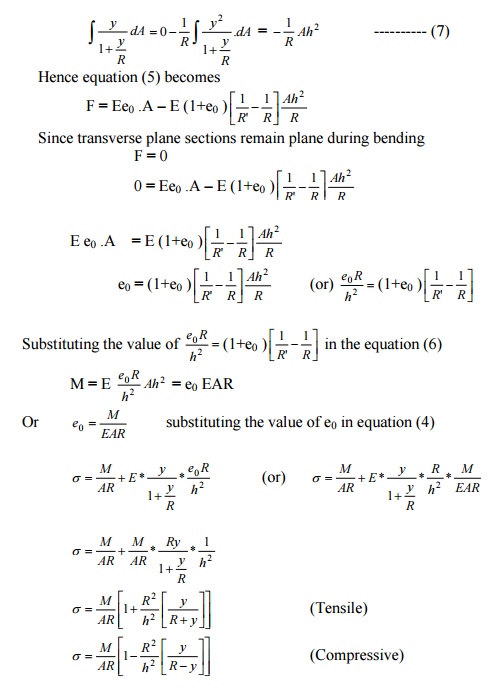

8 DERIVE THE STRESSES IN CURVED BARS US

ING WINKLER-BACH THEORY

The simple bending formula, however, is not

applicable for deeply curved beams where

the neutral and centroidal axes do not coincide. To deal with such cases

Winkler -Bach Theory is used.

A bar ABCD initially; in its unstrained state.

Let AB?CD? be

th bar.

Let R =

Radius of curvature of the centroidal axis HG.

Y = Distance of the fiber EF from the

centroidal layer HG.

R? = Radius

of curvature of

HG?

M = Uniform bending moment applied to the

beam (assumed positive when tending to

increase the curvature)

R? =

Original angle subtended by the centroidal axis HG at its centre of curvature O and

q? =

Angle subtended by

HG? (after ben q?

For finding

the strain and stress normal to the section, consider the fibre EF at a

distance y from the centroidal axis.

Let ? be the

stress in the strained layer EF same

layer.

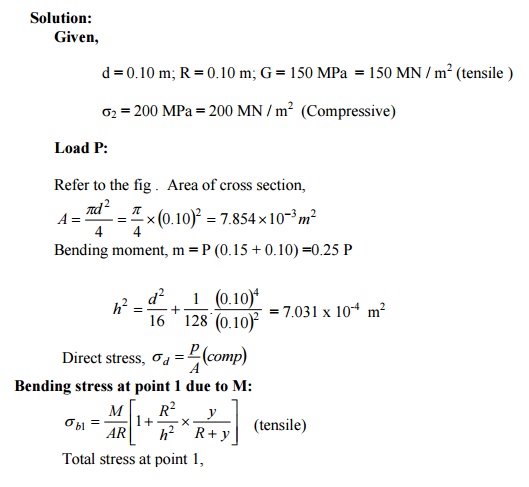

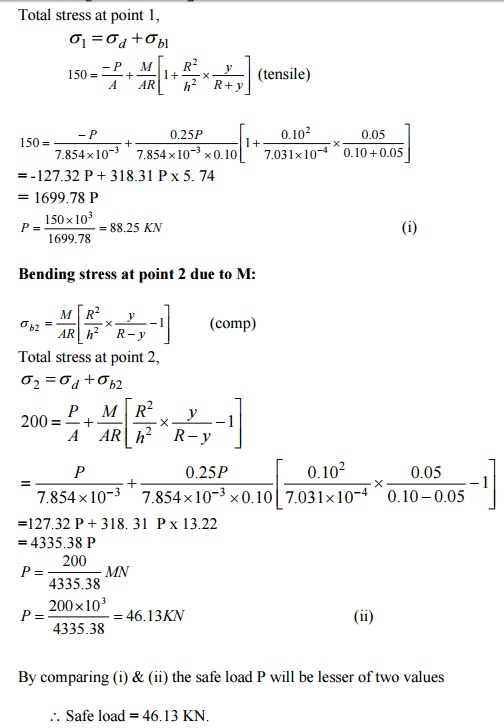

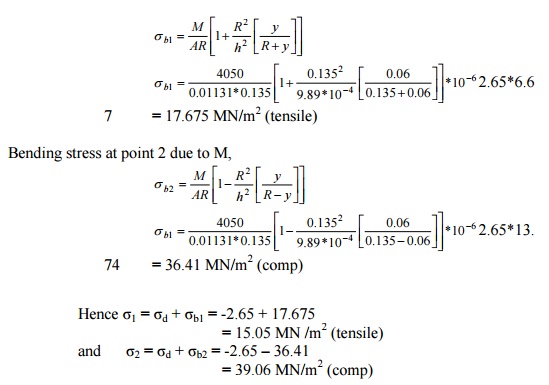

The curved member shown in fig. has a solid

circular cross -section 0.01 m in diameter.

If the maximum tensile and compressive stresses in the member are not to

exceed 150 MPa and 200 MPa. Determine

the value of load P that can safely be carried by the member.

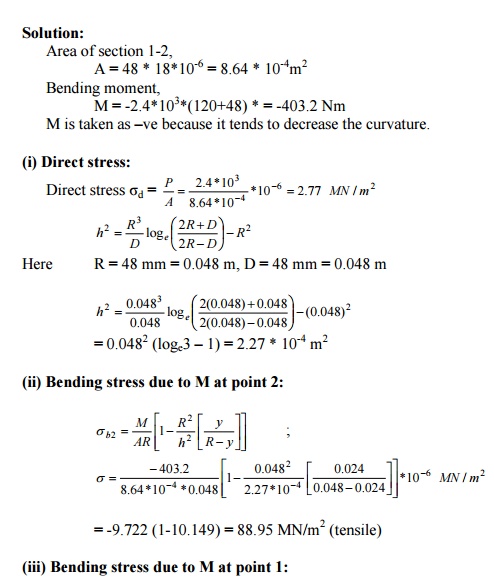

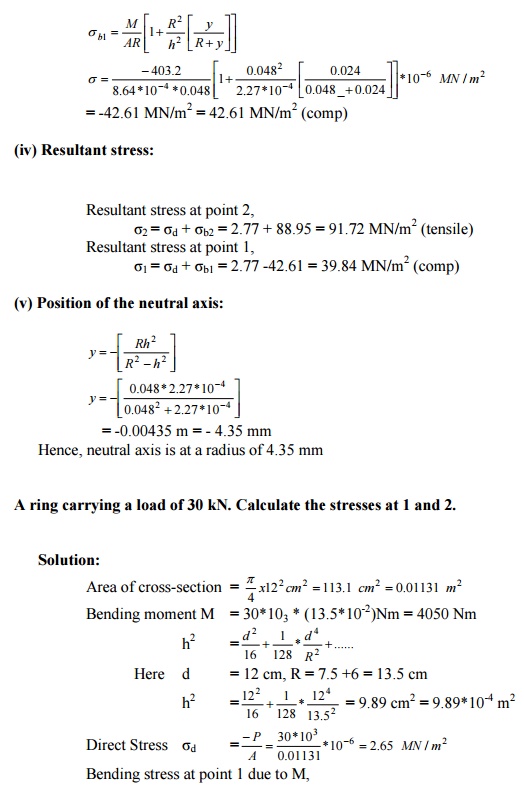

A frame subjected to a load of 2.4 kN. Find

(i) The resultant stresses at a point 1 and

2; (ii) Position of neutral

axis.

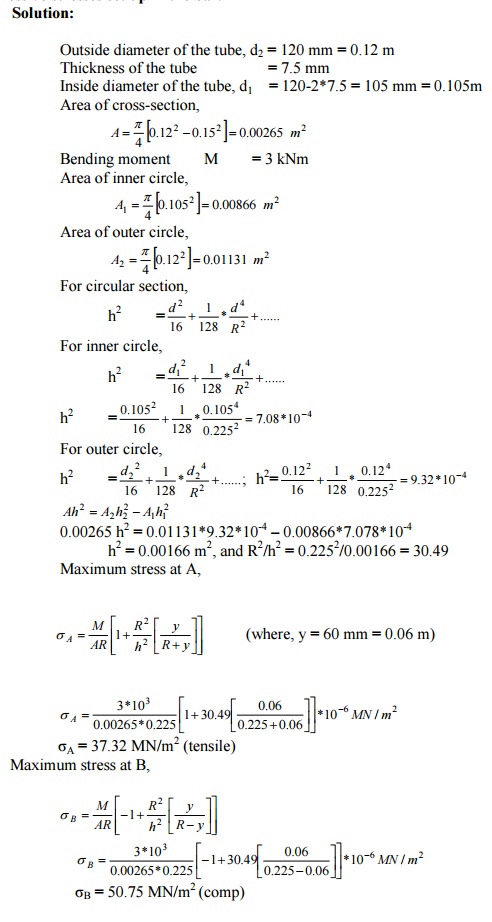

A curved bar is formed of a tube of 120 mm

outside diameter and 7.5 mm thickness. The

centre line of this is a circular arc of radius 225 mm. The bending

moment of 3 kNm tending to increase

curvature of the bar is applied. Calculate the maximum tensile and compressive stresses set up in the bar.

A CURVED BEAM HAS A

T-SECTION. THE INNER RADIUS IS 300 MM. WHAT IS

THE ECCENTRICITY OF THE SECTION?

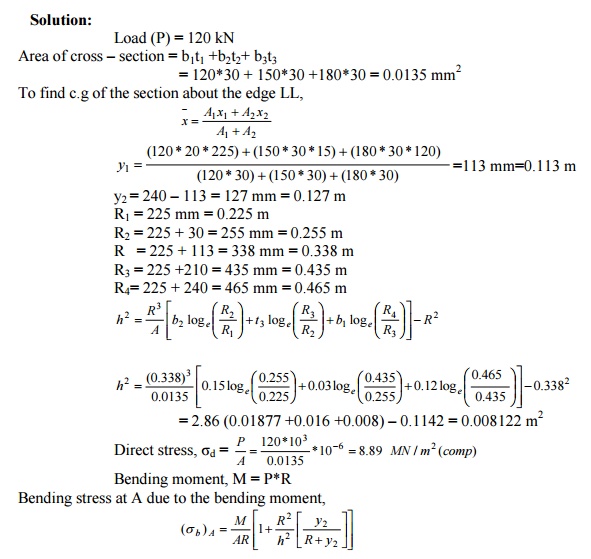

C- FRAME SUBJECTED TO A LOAD OF 120 KN.

DETERMINE THE STRESSES AT A AND B.

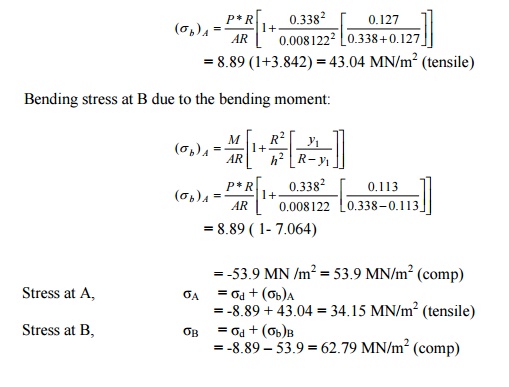

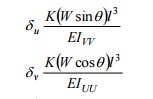

DERIVE THE FORMULA FOR THE DEFLECTION OF BEAMS

DUE TO

UNSYMMETRICAL BENDING

Solution:

Tthe

transverse section of the beam with centroid G. XX and YY are two rectangular co-ordinate axes

and UU and

VV are the

pri XY set of co-ordinates axes.

W is the load acting along the line YY on the section of the beam. The load W can be resolved into the following

two components:

(i)

W

sin ? ……

along UG

(ii)

W

cos ? ……

along VG

Let,u= Deflection?

caused by the

component W si

VV axis, and

v = Deflection

caused long by the thelineGV due component

to bendingabodt W co

UU axis.

Then depending

upon the end u

conditionsandvare?givenby

of th

where, K = A constant depending on the end

conditions of the beam and position of

the load along the beam, and

l = length of

the beam

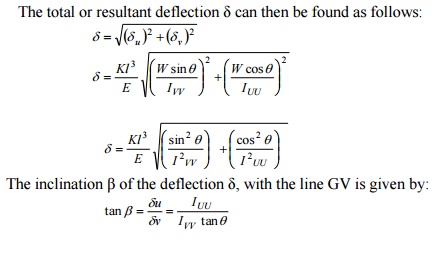

The total

or resultant deflection

? can then

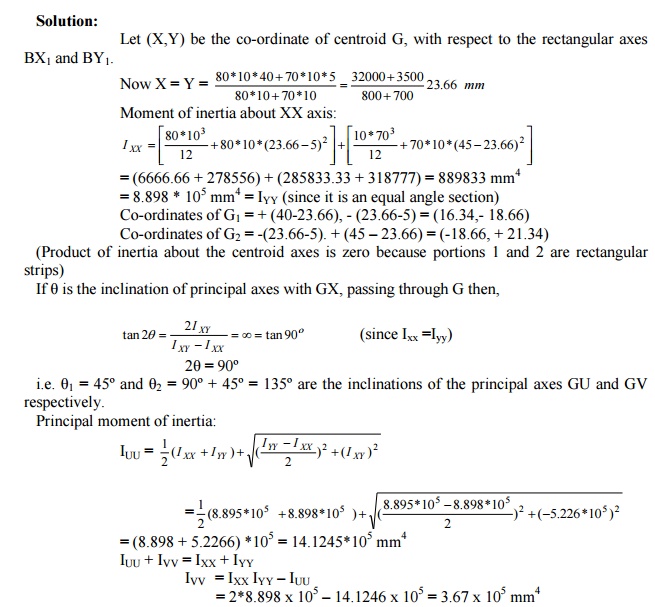

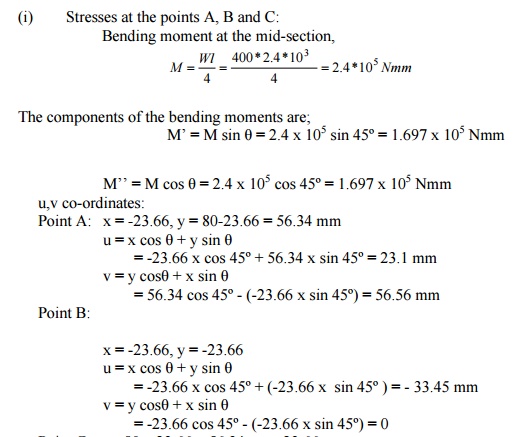

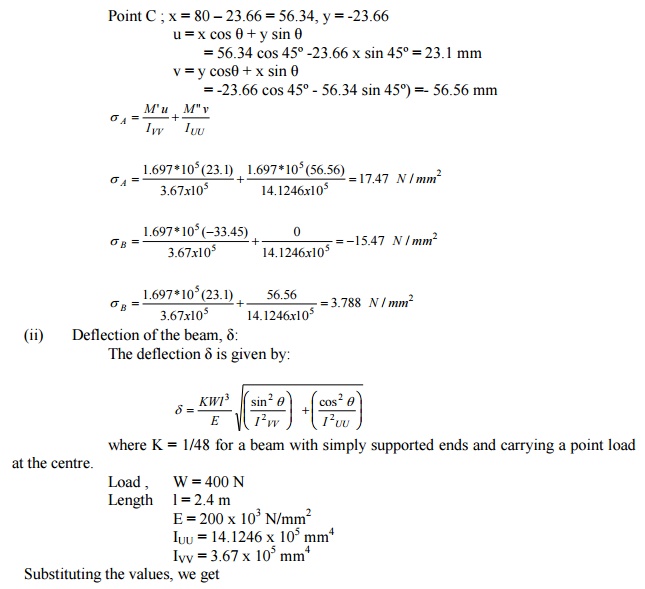

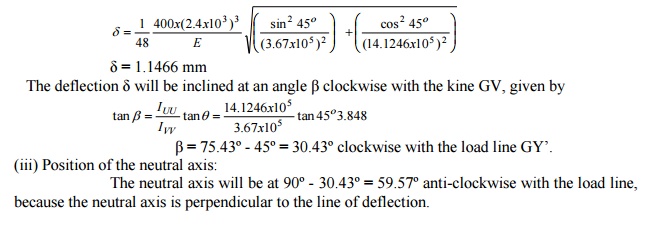

A 80 mm x 80 mm x 10 mm angle section shown in

fig. is used as a simply supported beam

over a span of 2.4 m. It carries a load of 400 kN along the line YG,

where G is the centroid of the section.

Calculate (i) Stresses at the points A, B and C of the mid -section of the beam (ii) Deflection of the beam at the mid-section

and its direction with the load line (iii)

Position of the neutral axis. Take E = 200 GN/m2

10

STATE THE PARALLEL AXES AND PRINCIPAL MOMENT OF INERTIA

If the two axes about which the product of

inertia is found, are such , that the

product of inertia becomes zero, the two axes are then called the

principle axes. The moment of inertia

about a principal axes is called the principal moment of inertia.

11 STRESS CONCENTRATION

The term stress gradient is used to indicate

the rate of increase of stress as a stress

raiser is approached. These localized stresses are called stress

concentration.

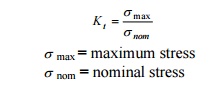

12 STRESS- CONCENTRATION FACTOR

It is defined as the ratio of the maximum

stress to the nominal stress.

?max = maximum

stress

?nom = nominal

stress

13 FATIGUE STRESS CONCENTRATION FACTOR

The fatigue stress -concentration factor (Kf

) is defined as the ratio of flange limit

of unnotched specimen to the fatigue limit of notched specimen under

axial (or) bending loads.

K

f =1+q(Kt -1)

Value of q ranges from zero to one.

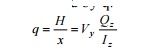

14 SHEAR FLOW

Shear flow is defined as the ratio of

horizontal shear force H over length of the

beam x. Shear flow is acting along the longitudinal surface located at

discharge y1.Shear flow is

defined by q.

H

= horizontal shear force

15 EXPLAIN THE

POSITION OF SHEAR CENTRE IN VARIOUS SECTIONS

(i) In case of a beam having two axes of

symmetry, the shear centre coincides with the centroid.

(ii)

In case of sections having one axis of

symmetry, the shear centre does not

coincide with the centroid but lies on the axis of symmetry.

16 STATE THE

PRINCIPLES INVOLVED IN LOCATING THE SHEAR CENTRE

The principle involved in locating the shear

centre for a cross -section of a beam is that the loads acting on the beam must

lie in a plane which contains the resultant shear force on each cross-section of the beam as

computed from the shearing stresses.

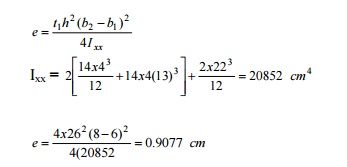

DETERMINE THE POSITION OF SHEAR CENTRE OF THE

SECTION OF THE BEAM

Solution:

t1

= 4 cm, b1 = 6 cm, b2 = 8 cm h1 = 30 -4 = 26 cm

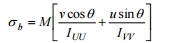

17 STATE THE STRESSES DUE TO

UNSYMMETRICAL BENDING

?b = bending stress in the curved bar

M

= moment due to the load applied

IUU = Principal moment of inertia in the

principal axes UU

I VV = Principal moment of inertia in

the principal axes VV

18 FATIGUE

Fatigue is defined as the failure of a

material under varying loads, well below the ultimate static load, after a

finite number of cycles of loading and unloading.

19 TYPES OF FATIGUE

STRESS

(i)

Direct stress

(ii)

Plane bending

(iii)

Rotating bending

(iv)

Torsion

(v)

Combined stresses

(a)

Fluctuating or alternating stress

(b)

Reversed stress.

20 STATE THE REASONS

FOR STRESS- CONCENTRATION

When a large stress gradient occurs in a

small, localized area of a structure, the

high stress is referred to as a stress concentration. The reasons for

stress concentration are

(i) discontinuities in continuum

(ii) contact forces.

21 CREEP

Creep can be defined as the slow and

progressive deformation of a material with

time under a constant stress.

Related Topics