Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Production Planning and Control Systems

Shop Floor Control

SHOP FLOOR

CONTROL

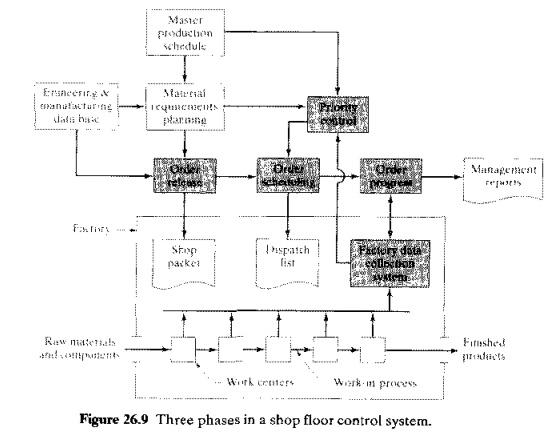

Shop floor control is

concerned with Ihe release of production orders to the factory, monitoring and

controlling the progress of the orders through the various work centers, and

acquiring current information on the status of the orders. A typical shop flour

control system consists of three phases: (1) order release, (2) order

scheduling, and (3) order progress. The three phases and their connections to

other functions in the production management system are pictured in Figure

26.9. In today's implementation of shop floor control, these phases are

executed hy a com hi nation of computer and human resources, with a growing

proportion accomplished by computer

automated methods.

Order Release

"he

order release phase of shop floor control provides the documentation needed to

process a production order through the factory. The collection of document is

sometimes called the shop packet. It

consists of: (1) the route sheet,

which documents the process plan for the item to be produced: (2) material requisitions [0 draw the necessary raw materials

from inventory: (3)job cards or other

means to report direct labor time devoted to the order and to indicate progress

uf the order through the factory; (4) move

tickets to authorize the material handling personnel to transport parts

between work centers in the factory if this kind of authorization is required;

and (5) parts list, if required for

assembly jobs. In rho operation of a conventional factory, which relies heavily

on manual labor, these are paper documents that move with the production order

and are used to track its progress through the shop. In a modern factory,

automated identification and data capture technologies (Chapter 12) are used to

monitor the status of production orders, thus rendering the paper documents (or

at least some of them) unnecessary. We explore these factory data collection

systems in Section 26.4.4.

The order

release module is driven by two inputs, as indicated in Figure 26,9. The first

is the authorization to produce that derives from the master schedule. This

authorization proceeds through MRP which generates work orders with scheduling

information. The second input to the order release module is the engineering and

manufacturing data base which provides the product structure and process

planning information needed to prepare the various documents that accompany the

order through the shop.

Order Scheduling

The order

scheduling module follows directly from the order release module and assigns

the production orders to the various work centers in the plant. In effect,

order scheduling executes the dispatching function in PPC. The order scheduling

module prepares a dispatch list, which indicates which production

orders should be accomplished at the various work centers. It also provides information about relative priorities of

the different jobs, for example, by showing due dates for each job. In current

shop floor control practice, the dispatch list guides the shop foreman in

making Work assignments and allocating resources to different jobs so that the

master schedule can best be achieved.

The order

scheduling module in shop floor control is intended to solve two problems in

production control: (1) machine loading and (2) job sequencing. To schedule a

given

set of

production orders or jobs in the factory, the orders must first be assigned to

work centers. Allocating orders to work centers is referred to as machine loading. The term shop

loading is also

used, which refers to the loading of all machines in the plant. Since the total number of production orders usually

exceeds the number of work centers, each work center will have a queue of

orders waiting to be processed. The remaining question is: In what sequence

should these jobs be processed?

Answering

this question is the problem in job sequencing. Job sequencing involves determining the sequence in which the jobs

will be processed through a given work center.!o determine this sequence,

priorities are established among the jobs in the queue, and the jobs are

processed in the order of their relative priorities, Priority control is a term

used in production control to denote the function that maintains the appropriate

priority

levels

for the various production orders in the shop. As indicated in Figure 26.9,

priority control information is an important input in the order scheduling

module. Some of the dispatching rules used to establish priorities for production

orders in the plant include:'

First-come-first

serve. Jobs are processed in the order in which they arrive at the machine. One

might argue that this rule is the most fair.

Earliest due date.

Orders with earlier due dales

are given higher priorities.

Shortest

processing time. Orders with shorter processing times are given

higher priorities.

Least

slack time. Slack lime is defined as the difference between the

time remaining until due date and the

process time remaining. Orders with the least slack in their schedule are given

higher priorities.

Critical

ratio. The critical ratio is defined as the ratio of the time remaining until due date divided by the process time

remaining. Orders with the lowest critical ratio are given higher priorities.

When an

order is completed atone work center, it enters the queue at the next machine

in its process routing. That is, the order becomes part of the machine loading

for the next work center, and priority control is utilized to determine the sequence

of processing among the jobs at that machine.

The

relative priorities of the different orders may change over time. Reasons

behind these changes include: (1) lower or higher than expected demand for

certain products,

(2)

equipment breakdowns that cause delays in production, (3) cancellation of an

order by a customer, and (4) defective raw materials that delay an order. The

priority control function reviews the relative priorities of the orders and

adjusts the dispatch list accordingly.

Order Progress

The order

progress module in shop floor control monitors the status of the various orders

in the plant, WIP, and other characteristics that indicate the progress and

performance of production. The function of the order progress module is to

provide information that is useful in managing the factory based on data

collected from the factory. The information presented to production management

is often summarized in the form of reports, such as the following:

Work

order status reports. These reports indicate the status of production

orders. Typical information in the

report includes the current work center where each order is located, processing

hours remaining before completion of each order, whether the job is on-time or

behind schedule, and priority level.

Progress reports, A

progress report is used to report performance of the shop during a certain time

period (e.g., week or month in the master schedule).!! provides information on

how many orders were completed during the period, how many orders should have

been completed during the period but were not, and so forth.

Exception reports; An

exception report indicates the deviations from the production schedule (c.g .. overdue jobs]. and

similar exception information

Factory

Data Collection System

There arc

a variety of techniques used to collect data from the factory floor. These

techniques range from clerical methods which require workers to fill out paper

forms that are later compiled, to fully automated methods, that require no

human participation. The factory data

collection system (FDC system} consists of the various

paper documents, terminals, and automated devices located throughout the plant

for collecting data on shop floor operations. plus the means for compiling and

processing the data. The factory data collection system serves as an input to

the order progress module in shop Floor control. as illustrated in Figure 26.9.

It iv also an input to priority control, which affects order scheduling.

Examples of the types of data on factory operations collected by the FOC system

include: piece counts completed at a certain work center. direct labor time

expended on each order. parts that are scrapped. parts requiring rework, and

equipment down-time. The data collection system can also include the time

clocks used hy employees to punch in and out of work.

The

ultimate purpose of the factory data collection system is twofold (1) (0 supply status and performance

data to the shop floor control system and (2) to provide current information to

production foremen, plant management. and production control personnel To

accomplish this purpose. the factory data collection system must input data to

the plant computer system. In current Cl M technology. this is done using an

online mode, in which the data arc entered directly into the plant computer

system and are immediately available to the order progress module, The

advantage of online data collection is that the data file representing the

status of the shop can be kept current at all times. As changes in order

progress are reported. these changes arc immediately incorporated into the shop

status file. Personnel with a need to know can access this status in real-time

and be confident that they have the most up-to-date information on which to

base any decisions. Even though a modern FOC system is largely computerized.

paper documents are still used in factory operations, and our coverage includes

both manual (clerical) and automated systems.

Manua,1

(Clerical) Data Input Techniques. Manually oriented techniques of

factory data collection are those in which the production workers must read

from and fill out paper forms indicating order progress data. The forms are

subsequently turned in and compiled, using a combination of clerical and

computerized methods. The paper forms include:

Job traveler; This is a log sheet that travels

with the shop packet through the factory. Workers", ho spend time on the

order are required 10 record their times on the log sheet along with other data

such 'l'i the date, piece counts, defects. and so forth. The job traveler

becomes the chronological record of the processing of the order. The problem

with this method is irs inherent incompatibility with the

principles of real-time data collection. Since the job traveler moves with the

order, it is not readily available for compiling current order progress.

Employee

time sheets. In the typical operation of this method. a daily

time sheet is prepared for each

worker, and the worker must fill out the form to indicate work that he/she

accomplished during the day. Typical data entered on the form include order

number, operation number on the route sheet, number of pieces completed during

the day, and time spent. Some of these data are taken from information contained

1ll the documents traveling with the order (e.g., typical documents traveling

with the order include one or more engineering drawings and route sheets). The

time sheet is turned in daily, and order progress information is compiled

(usually by clerical staff).

Operation

tear strips. With this technique, the traveling documents

include a set of preprinted tear

strips that can be easily separated from the shop packet. The preprinted data

on each tear strip includes order number and route sheet details. When a worker

finishes an operation or at the end of the shift, one of the tear strips is

torn off. piece count and trme data are recorded by the worker. and the form is

turned in to report order progress.

Prepunched

cards. This is essentially the same technique as the tear strip method. except

that prepunched computer cards are included with the shop packet instead of

tear strips. The prepunched cards contain the same type of order data, and the

workers must write the same kind of production data onto the card, The

difference in the use of pre punched cards is that in compiling the daily order

progress, mechanized data processing procedures can be used to record some of

the data.

There arc

problems with all of these manually oriented data collection procedures. Thev

all rely on the cooperation and clerical accuracy of factory workers to record

data onto a paper document. There are invariably errors in this kind of

procedure. Error rates associated with handwritten entry of data average about

3% (one error out of 30 data entries). Some of the errors can be detected by

the clerical staff that compiles the order progress records. Examples of

detectable errors include: wrong dates, incorrect order numbers (the clerical

staff knows which orders are in the factory, and they can usually figure out

when an erroneous order number has been entered by a worker), and incorrect

operation numbers on the route sheet. (If the worker enters a certain operation

number, but the preceding operation number has not been started, then an error

has been made.) Other errors are more difficult to identify. If a worker enters

a piece count of 150 pieces that represents the work completed in one shift

when the batch size is 250 parts, this is difficult for the clerical staff to

verify. If a different worker on the following day completes the batch and also

enters a piece count of 150, then it is obvious that one of Ihe workers

overstated his/her production, but which one? Maybe both.

Another

problem is the delay in submitting tile order progress data for compilation. There

is a time lapse in each of the methods between when events occur in the shop

and when the paper data representing those events are submitted. The job

traveler method is the worst offender in this regard. Here the data might not

be compiled until the order has been completed, too late to take any corrective

action. This method is of little value in a shop floor control system. The

remaining manual methods suffer a one-day delay since the shop data are

generally submitted at the end of the shift, and a summary compilation is nor

available until the following day. In addition to the delay in submitting the

order dahl, there is also a delay associated with compiling the data into

useful reports. Depending on how the order progress procedures are organized,

the compilation may add several days to the reporting cycle.

Automated and Semi Automated Data

Collection Systems. Because of the

problems associated with the manual/clerical procedures. techniques have

been developed that use data collection terminals located in the factory. Data

collection terminals require workers to input data relative to order progress

using simple keypads or conventional alphanumeric keyboards. Data entered by

keyboard are subject to error rates of around O.3%"(one error in

300 data entries), <III order uf magnitude improvement in

data accuracy over handwritten entry. Also, error-checking routines can be

incorporated into the entry procedures to detect syntax and certain other types

of errors. Because of their widespread use in our society. PCs are becoming

more and more common in the factory, both for collection of data and for

presenting engineering and production data to shop personnel.

The data

entry methods also include more automated input technologies such as optical

bar code readers or magnetic card readers. Certain types of data such as order

number. product identification, and operation sequence number can be entered

with automated techniques using bar-coded or magnetized cards included with the

shop documents (refer back to the barcoded route sheet in Figure 12.7).

Using

either PCs or terminals that combine keypad entry with bar code technology,

there are various configurations of data collection terminals that can be

installed in the factory. These configurations include:

One

centralized terminal In this arrangement there is a single terminal located

centrally in the plant. This requires all workers to walk from their

workstations to the central location when they must enter the data. If the

plant is large, this becomes inconvenient. Also, use of the terminal tends to

increase at time of shift change, resulting in significant lost time for the

workers.

Satellite

terminals. In this configuration, there are multiple data

collection terminals located throughout the plant. The number and locations are

designed to strike a balance between minimizing the investment cost in

terminals and maximizing the convenience of the plant workers.

Workstation

terminals. The most convenient arrangement for workers is to

have a data collection terminal

available at each workstation. This minimizes the time lost in walking to

satellite terminals or a single central terminal. Although the investment cost

of this configuration is the greatest, it may he justified when the number of

data transactions is relatively large and when the terminals are also designed

to collect certain data automatically.

The trend

in industry is toward more use of automation in factory data collection

systems. Although the term "automation" is used,many of the

techniques require the participation of human workers; hence, we have included

"semi-automated" in the subtitle for this category of data collection

system

Related Topics