Chapter: Mechanical : Design of Machine Elements : Design of Bearings Miscellaneous Elements

Rolling Contact Bearings

Rolling Contact Bearings

In rolling contact bearings, the contact between the bearing surfaces is rolling instead of sliding as in sliding contact bearings. We have already discussed that the ordinary sliding bearing starts from rest with practically metal-to-metal contact and has a high coefficient of friction. It is an outstanding advantage of a rolling contact bearing over a sliding bearing that it has a low starting friction. Due to this low friction offered by rolling contact bearings, these are called antifriction bearings.

1 Advantages and Disadvantages of Rolling Contact Bearings over Sliding Contact Bearings

The following are some advantages and disadvantages of rolling contact bearings over sliding contact bearings

Advantages

Low starting and running friction except at very high speeds.

Ability to withstand momentary shock loads.

Accuracy of shaft alignment.

Low cost of maintenance, as no lubrication is required while in service.

Small overall dimensions.

Reliability of service.

Easy to mount and erect.

Cleanliness.

Disadvantages

More noisy at very high speeds.

Low resistance to shock loading.

More initial cost.

Design of bearing housing complicated.

2 Types of Rolling Contact Bearings

Following are the two types of rolling contact bearings:

Ball bearings; and

Roller bearings

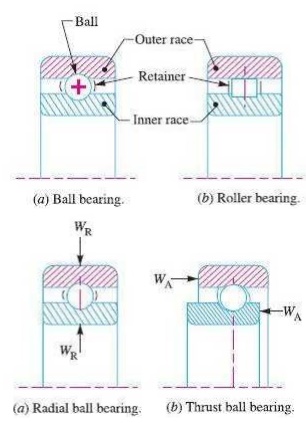

The ball and roller bearings consist of an inner race which is mounted on the shaft or journal and an outer race which is carried by the housing or casing. In between the inner and outer race, there are balls or rollers as shown in Fig.

A number of balls or rollers are used and these are held at proper distances by retainers so that they do not touch each other. The retainers are thin strips and is usually in two parts which are assembled after the balls have been properly spaced. The ball bearings are used for light loads and the roller bearings are used for heavier loads. The rolling contact bearings, depending upon the load to be carried, are classified as:

Radial bearings, and

Thrust bearings.

The radial and thrust ball bearings are shown in Fig (a) and (b) respectively. When a ball bearing supports only a radial load (WR), the plane of rotation of the ball is normal to the centre line of the bearing, as shown in Fig (a). The action of thrust load (WA) is to shift the plane of rotation of the balls, as shown in Fig (b). The radial and thrust loads both may be carried simultaneously.

Related Topics