Chapter: Mechanical : Design of Machine Elements : Design of Bearings Miscellaneous Elements

Design of Bearings Miscellaneous Elements

DESIGN OF

BEARINGS MISCELLANEOUS ELEMENTS

Sliding

Contact Bearings

A bearing is a machine element which support

another moving machine element (known as journal). It permits a relative motion

between the contact surfaces of the members, while carrying the load. A little

consideration will show that due to the relative motion between the contact

surfaces, a certain amount of power is wasted in overcoming frictional

resistance and if the rubbing surfaces are in direct contact, there will be

rapid wear. In order to reduce frictional resistance and wear and in some cases

to carry away the heat generated, a layer of fluid (known as lubricant) may be

provided. The lubricant used to separate the journal and bearing is usually a

mineral oil refined from petroleum, but vegetable oils, silicon oils, greases

etc., may be used.

1

Classification of Bearings

Though the bearings may be classified in many ways,

yet the following are important from the subject point of View:

1.1

Depending upon the direction of load to be supported.

The

bearings under this group are classified as:

Radial bearings, and

Thrust bearings.

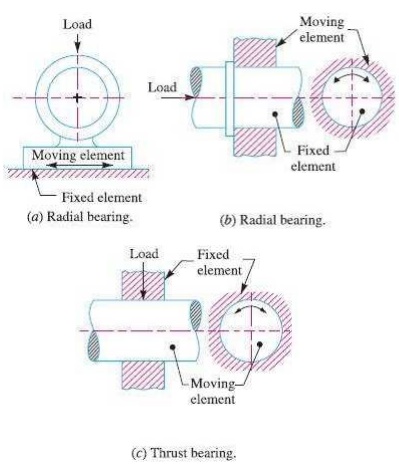

In radial

bearings, the load acts perpendicular to the direction of motion of the moving

element as shown in Fig (a) and (b). In thrust bearings, the load acts along

the axis of rotation as shown in Fig (c).

1.2

Depending upon the nature of contact. The bearings under this group are

classified as:

Sliding contact bearings, and

Rolling contact bearings.

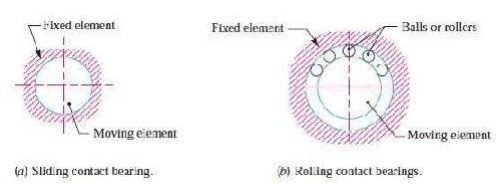

In

sliding contact bearings, as shown in Fig (a), the sliding takes place along

the surfaces of contact between the moving element and the fixed element. The

sliding contact bearings are also known as plain bearings.

In

rolling contact bearings, as shown in Fig (b), the steel balls or rollers, are

interposed between the moving and fixed elements. The balls offer rolling

friction at two points for each ball or roller.

2 Types of

Sliding Contact Bearings

The sliding contact bearings in which the sliding

action is guided in a straight line and carrying radial loads, as shown in Fig

(a), may be called slipper or guide bearings. Such

type of bearings are usually found in cross-head of steam engines. The sliding

contact bearings in which the sliding action is along the circumference of a

circle or an arc of a circle and carrying radial loads are known as journal or sleeve

bearings. When the angle of contact of the bearing with the journal is 360° as

shown in Fig (a), then the bearing is called a full journal bearing. This

type of bearing is commonly used in industrial machinery to accommodate bearing

loads in any radial direction.

When the angle of contact of the bearing with the

journal is 120°, as shown in Fig (b), then the bearing is said to be partial

journal bearing. This type of bearing has less friction than full

journal bearing, but it can be used only where the load is always in one

direction. The most common application of the partial journal bearings is found

in rail road car axles. The full and partial journal bearings may be called as clearance

bearings because the diameter of the journal is less than that of bearing.

When a partial journal bearing has no clearance

i.e. the diameters of the journal and bearing are equal, then the bearing is

called a fitted bearing, as shown in Fig (c). The sliding contact bearings,

according to the thickness of layer of the lubricant between the bearing and

the journal, may also be classified as follows:

Thick film bearings. The thick

film bearings are those in which the working surfaces are completely

separated from each other by the lubricant. Such type of bearings are also

called as hydrodynamic lubricated bearings.

Thin film bearings. The thin

film bearings are those in which, although lubricant is present,

the working surfaces partially contact each other atleast part of the time.

Such type of bearings are also called boundary lubricated bearings.

Zero film bearings. The zero

film bearings are those which operate without any lubricant present.

Hydrostatic

or externally pressurized lubricated bearings. The

hydrostatic bearings are those which can support steady

loads without any relative motion between the journal and the bearing. This is

achieved by forcing externally pressurized lubricant between the members.

Rolling

Contact Bearings

In rolling contact bearings, the contact between

the bearing surfaces is rolling instead of sliding as in sliding contact

bearings. We have already discussed that the ordinary sliding bearing starts

from rest with practically metal-to-metal contact and has a high coefficient of

friction. It is an outstanding advantage of a rolling contact bearing over a

sliding bearing that it has a low starting friction. Due to this low friction

offered by rolling contact bearings, these are called antifriction

bearings.

1

Advantages and Disadvantages of Rolling Contact Bearings over Sliding Contact

Bearings

The following are some advantages and disadvantages

of rolling contact bearings over sliding contact bearings

Advantages

Low

starting and running friction except at very high speeds.

Ability

to withstand momentary shock loads.

Accuracy

of shaft alignment.

Low cost

of maintenance, as no lubrication is required while in service.

Small

overall dimensions.

Reliability

of service.

Easy to

mount and erect.

Cleanliness.

Disadvantages

More

noisy at very high speeds.

Low

resistance to shock loading.

More

initial cost.

Design of

bearing housing complicated.

2 Types of

Rolling Contact Bearings

Following

are the two types of rolling contact bearings:

Ball bearings; and

Roller bearings

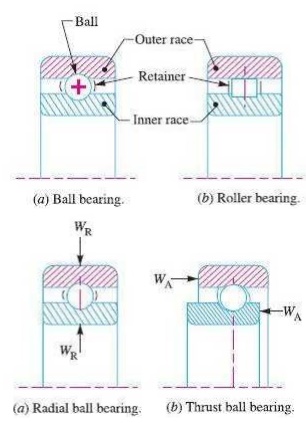

The ball and roller bearings consist

of an inner race which is mounted on the shaft or journal and an outer race

which is carried by the housing or casing. In between the inner and outer race,

there are balls or rollers as shown in Fig.

A number of balls or rollers are used and these are

held at proper distances by retainers so that they do not touch each other. The

retainers are thin strips and is usually in two parts which are assembled after

the balls have been properly spaced. The ball bearings are used for light loads

and the roller bearings are used for heavier loads. The rolling contact

bearings, depending upon the load to be carried, are classified as:

Radial bearings, and

Thrust bearings.

The radial and thrust ball bearings are shown in

Fig (a) and (b) respectively. When a ball bearing supports only a radial load

(WR), the plane of rotation of the ball is normal to the centre line of the

bearing, as shown in Fig (a). The action of thrust load (WA) is to shift the

plane of rotation of the balls, as shown in Fig (b). The radial and thrust

loads both may be carried simultaneously.

Related Topics