Chapter: Civil : Repair and Rehabilitation of Structures : Maintenance and Repairs Strategies

Repair and Rehabilitation of Structures: Maintenance and Repairs Strategies

MAINTENANCE AND REPAIRS STRATEGIES

Maintenance, repair and

rehabilitation, Facets of Maintenance, importance of Maintenance Various

aspects of Inspection, Assessment procedure for evaluating a damaged structure,

Causes of deterioration

Maintenance

Maintenance Engineering is

defined as the work done to keep the civil Engineering structures and work in

conditions so as to enable them to carry out the functions for which they are

constructed.

It is preventive in nature.

Activities include inspection and works, necessary to fulfill the intended

function, or to sustain original standard of service.

Scope of maintenance

ü Petty

repairs, replacements and structural repairs of buildings, white and color

washing, distempering and painting at prescribed intervals

ü Repair

and renewal of furniture

ü Operation,

periodical maintenance, repairs renewals of machinery and equipment for

electric etc

ü Repair of

roads,culvets and resurfacing the roads

1.Facts of Maintenance

Aims of

Maintenance work classified as

ü The

avoidance of accidents, which may harm people or plant

ü The

continued operation of a facility

ü The

protection of the capital investment in the asset

2.Maintenance work is classified

as

ü Preventive

maintenance

ü Remedial

maintenance

ü Routine

maintenance

ü Special

maintenance

§ Maintenance work is classified as

The maintenance work done before the defects occurred in the

structure is called preventive structure

2.1.Remedial maintenance

It is the maintenance done after the defects in the structure.

It involves the following basic steps.

ü Finding

the deterioration

ü Determining

the clause

ü Evaluating

the strength of the existing structures

ü Evaluating

the need of the structures

ü Selecting

and implanting the repair procedure

2.2.Routine maintenance

It is the service maintenance attended to the structure

periodically. It is depends upon specifications and materials of structure,

purpose, intensity and condition of use.

2.3.Special maintenance

It is the work done under special condition and requires

sanction and performed to rectify heavy damage.

3.Importance of Maintenance

various aspects of Inspection

ü Improves

the life of structure

ü Improved

life period gives better return on investment

ü Better

appearance and aesthetically appealing

ü Leads to

quicker detection of defects and hence remedial measures

ü Prevents

major deterioration that leads to collapse

ü Ensures

safely to occupants

ü Ensures

feeling of confidence by the user

Daily Routine Maintenance

ü Basically

an inspection oriented and may not contain action to be taken

ü Help in

identifying major changes, development of cracks, identifying new cracks etc

ü Inspection

of all essential items by visual observation

ü Check on

proper function of sewer, water lines, wash basins, sinks etc

ü Check on

drain pipes from roof, during rainy season

Weekly Routine Maintenance

ü Electrical Accessories

ü Flushing sewer line

ü Leakage of water line

Monthly Routine Maintenance

ü Cleaning Doors, windows, etc

ü Checking Septic Tank/Sewer

ü Observation for cracks in the

elements

ü Cleaning of overhead tanks

Yearly Routine Maintenance

ü Attending

to small repairs and white washing

ü Painting

of steel components exposed to weather

ü Check of

displacements and remedial measures

Stages of inspection

A. Inspection

Collect

data at specified intervals in specified form

B. Analysis

Add latest information to database

ii.

Examine progression of defects

iii.

Relate defects to action criteria

C. Action possibilities

i.

Note and wait for the next inspection

ii.

Alter inspection frequency

iii.

Institute repairs

iv.

Further detailed investigation

v.

Put safety procedures in place

5.Necessitation of the maintenance

The causes which necessitate the

maintenance effects the service and durability of the structure as follows:

ü Atmospheric

Agencis

ü Normal

wear and tear

ü Failure

of structure

5.1 Atmospheric Agencis

Rain: It is the

important source of water which affects the structure in the following ways:

Expansion And contraction

ü The

material is subjected to repetitive expansion and contraction while they become

wet and dry and develops the stresses

ü Dissolving

and carrying away minerals as it is universal solvent

Chemical: The water

available in nature contains acids and alkali and other compound in dissolved

form acts over the material to give rise, which is known as chemical

weathering.

i.

Wind:It is the agent, which

transports the abrasive material and assists the physical weathering.

ii.

Temperature: The diurnal, seasonal

and annual variation of the temperature, difference in temperature it

causes expansion and contraction.

5.2.Normal wear and tear

During the use of structure it is

subjected to abrasion and thereby it looses appearance and serviceability

5.3 Failure of structure

ü Improper

design- Due to incorrect, insufficient data regarding use, loading

and environmental conditions, selection of material and poor detailing.

ü Defective

construction-poor materials, poor workmanship, lack of quality

control and supervision.

ü Improper

use of structure- overloading, selecting the structure for the use

they not designed impurities from industrial fuel burning, sea water

minerals etc.

6.Inspection periods

ü Pre-monsoon

period

ü Monsoon

period

ü Post-monsoon

period

6.1 Pre-monsoon period

To decide the maintenance programmer to be done

before monsoon such as cleaning of drains, checking of roof leakage, collection

material etc

6.2Monsoon period

It is needless to mention that

the emergency work carried out in monsoon period.e.g: railway tracks, collapse

of roof etc.

6.3 Post-monsoon inspection

It is made to repair the damage

caused by water and draw up the programme of repair according to the

priorities.

7.Maintenance processes

ü Design

for maintainability

ü Preventive

maintenance

ü Predictive

maintenance

ü Reliability

centered maintenance

ü Reactive

maintenance

ü Spares

management

ü Maintenance

logistics support

ü Total

productive maintenance

ü Organizing

for maintenance

ü Computerized

maintenance management program

ü Statutory

requirements

8.Inspection of building

ü Condition

of wall paint

ü Condition

of paint on woodwork and grill

ü Condition

of flooring

ü Roof

leakage, leakage etc

ü Condition

of service fittings

ü Drainage

from terrace

ü Growth of

vegetation

ü Structural

defects like Crack, Settlement, and Deflection

9.Repair and rehabilitation

Repair is the technical aspect of

rehabilitation. It refers to the modification of a structure, partly or wholly

which is damaged in appearance or serviceability.

The following factors to be considered repair of

concrete structures:

ü The cause

of damage

ü Type,

shape and function of the structure

ü The

capabilities and facilities available with builders

ü The

availability of repair materials

9.1Stages of concrete repair

Repair of concrete structures is

carried out in the following stages:

ü Removal

of damaged concrete

ü Pre

treatment of surfaces and reinforcement

ü Application

of repair material

ü Restoring

the integrity of individual sections and strengthening of structure as a whole

9.2

Repair procedure

A repair

procedure may be selected to accomplish on or more of the following objectives:

ü To

increase strength or restore load carrying capacity

ü To

restore or increase stiffens

ü To

improve functional performance

ü To

provide water tightness

ü To

improve durability

ü To

prevent access of corrosive material to reinforcement

9.3 Types and classification of repair Types of

repair:

ü Cosmetic

treatments on surfaces

ü Partial

replacement of surface and subsurface material

ü

Additional of reinforcements and bonding materials

to strengthen the element

ü

Total replacement of the structural element

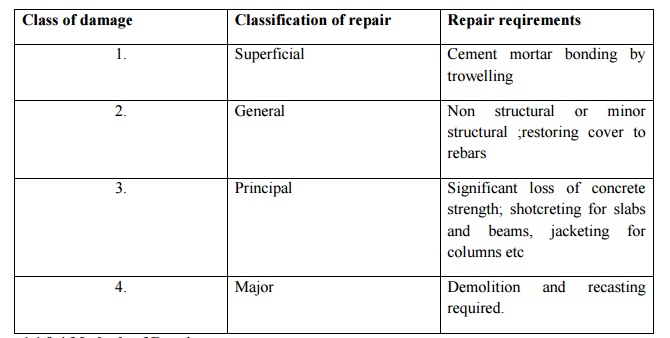

Classification of repair:

Classification

of repair : Repair reqirements

Superficial

: Cement mortar bonding by trowelling

General

: Non structural or minor structural

;restoring cover to rebars

Principal

: Significant loss of concrete strength;

shotcreting for slabs and beams, jacketing

for columns etc

Major :

Demolition and recasting required.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 9.4 Methods of Repairs

9.4 Methods of Repairs

The

following considerations are to be taken care of and observed:

ü Determination

of extent, location and width of cracks

ü Classification

of cracks as structural and non-structural

Dormant cracks:

Dormant cracks are caused by some event in the part, which is

not expected to recur. They remain constant in width, and may be repaired by

filling then with a rigid material.

Active cracks:

Do not remain constant in width, but open and close as the

structure in loaded, or due to thermal and hydras changes in the concrete.

Growth cracks:

Increase in width becomes the

original reason for their occurrence persists.

9.5 Applications:

The repair of cracks can be achieved with the

following techniques:

ü Resin

injection

ü Routing

and Sealing

ü Stitching

ü External

stressing

ü Bonding

ü Blanketing

ü Overlays

ü Dry pack

ü Vacuum

impregnation

ü Polymer

impregnation

9.6 Rehabilitations

The success of repair activity

depends on the identification of the root cause of the deterioration of the

concrete structures. The repairs can be done for the improvement of strength

and durability, thus extending the life of the structure, is not difficult to

achieve.

It is the processes of restoring

the structure to service level, once it had and now lost, strengthening

consists in endowing the structure with a service level, higher than that

initially planned by modifying the structure not necessarily damaged area.

The following steps are generally

used in the rehabilitation of distressed concrete structure:

ü Support

the structural members properly as required.

ü Remove

all cracked, spalled and loose concrete.

ü Clean the

exposed concrete surfaces and steel reinforcement

ü Provide

additional reinforcing bars, if the loss in reinforcement is more than 10%

ü Apply

protective coatings over the exposed/repaired surface.

9.6.1 Applications:

ü Shotcrete/Gunite

ü Resin

injection

ü Dry pack

and Epoxy-bonded dry pack

ü Slab

jacking Technique

ü Sprayed

concrete

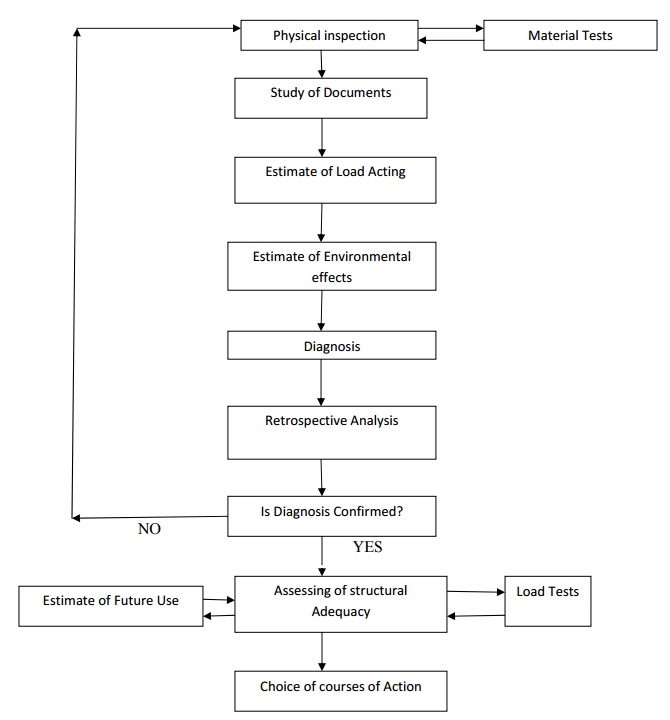

10Assessment procedure for

evaluating a damaged structure The following steps may necessary:

ü Physical

Inspection of damaged structure

ü Prepartion

and documenting the damages

ü Collection

of samples and carrying out tests both in-situ and in lab

ü Studying

the documents including structural aspects

ü Estimation

of loads acting on the structure

ü Estimate

of environmental effects including soil structure interaction

ü Diagnosis

ü Taking

preventive steps not to cause further damage

ü Retrospective

analysis to get the diagnosis confirmed

ü Assessment

of structural adequacy

ü Estimation

on future use

ü Remedial

measures necessary to strengthen and repairing the structure

ü Post

repair evaluation through tests

ü Load test

to study the behavior

ü Choice of course of action for the restoration of structure.

10.1Flowchart for Assessment

procedure for damaged structure

11Causes of Deterioration

a) Design and construction Flows

Design of concrete structures

governs the performance of concrete structures. Well-designed and detailed

concrete structure will show less deterioration in comparison with poorly

designed and detailed concrete, in this similar condition. The beam-column

joints are particularly probe to defective concrete, if detailing and placing

of reinforcement is not done properly.

b) Environmental effects

Micro-cracks present in the

concrete are the source of access of moisture and atmospheric carbon-di-oxide

into the concrete, which attack reinforcement and react with various

ingredients of concrete. In aggressive environment, concrete structures will

deteriorate faster and strength/life of concrete structures will be severely

reduced.

c) Usage of poor Quality Material

Quality of materials to be used

in construction, should be ensured by means of various tests, as specified in

the IS codes. Alkali-aggregate and Sulphate attack results in early

deterioration. Clayed materials in the fine aggregates may weaken the

mortar-aggregate bond, and reduce the strength.

d) Quality of Supervision

Construction work should be

carried out as per the specifications. Adherence to specified water-cement

ratio controls strength, permeability and durability of concrete. Insufficient

vibration may result in porous and honey-combed concrete, whereas excess

vibration may cause segregation.

e) Deterioration due to Corrosion

ü Spalling

of concrete cover

ü Cracks

parallel to the reinforcement

ü Spalling

at edges

ü Swelling

of concrete

ü Dislocation

Related Topics