Chapter: Mechanical Engineering : Refrigeration

Refrigeration

Refrigeration:

1 Vapour Compression Refrigeration System

2 Vapour Absorption Refrigeration System

3 Comparison Between Vapour Compression & Vapour Absorption Refrigeration Systems

REFRIGERATION:

·

It is defined as the process of providing and

maintaining a temperature well below that of surrounding atmosphere.

·

In other words refrigeration is the process

of cooling substance.

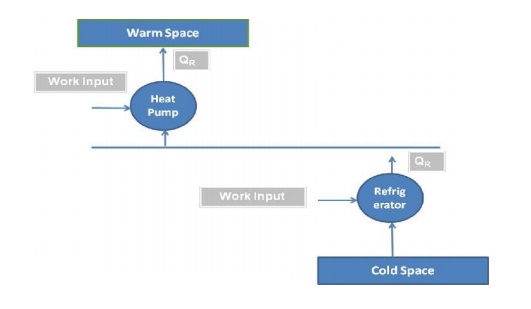

Refrigerators and heat pumps:

If the main purpose of the

machine is to cool some object, the machine is named as refrigerator.

If the main purpose of machine is to heat a medium

warmer than the surroundings, the machine is termed as heat pump.

Terminologies of Refrigeration:

Refrigerating

Effect (N):

It is defined as the quantity of heat extracted

from a cold body or space to be cooled in a given time.

N= Heat extracted from the cold space Time taken

Specific

Heat of water and ice :

It is the quantity of heat required to raise or

lower the temperature of one kg of water (or ice), through one kelvin or (10

c) in one second.

Specific

heat of water, Cpw = 4.19

kJ/kg K

Specific

heat of ice, Cpice = 2.1

kJ/kg K.

Capacity

of a Refrigeration Unit :

·

Capacity of a refrigerating machines are

expressed by their cooling capacity.

The standard unit used for expressing the capacity

of refrigerating machine is ton of refrigeration.

· One ton of refrigeration

is defined as, “the quantity of heat effect) to freeze one ton of

water Heat extracted from at oo c = latent heat of ice into one ton

of ice in a duration of 24 hours at 0o C”.

Latent

heat of ice= 336 kJ/kg i.e., 336 kJ of heat should be extracted one kg of water

at

0o C to convert it into ice.

One ton of refrigeration

= 336x1000 kJ/24 hrs. = 336x1000 kJ/min

=24x60

One ton of refrigeration

= 233.333 kJ/min

= 3.8889 kJ/sec

Co efficient of Performance

It is defined as the ratio of

heat extracted in a given time (refrigerating effect) to the work input.

Co efficient of performance = Heat extracted in

evaporator Work Input

Co

efficient of performance =

Refrigerating Effect

Work

Input

Co

efficient of performance = NW

The COP is always greater than 1 and known as theoretical

coefficient of performance.

Applications of Refrigeration:

In chemical industries, for separating and liquefying the

gases. In manufacturing and storing ice.

For the preservation of perishable food items in cold

storages. For cooling water.

For controlling humidity of air manufacture and heat treatment

of steels. For chilling the oil to remove wax in oil refineries.

For the preservation of tablets and medicines in

pharmaceutical industries. For the preservation of blood tissues etc.,

For comfort air conditioning the hospitals, theatres, etc.,

Properties

of Refrigeration:

A good refrigerant should have high latent heat of

vapourisation. It should have low boiling and low freezing point.

It should be non toxic and should non corrosiveness It should

be non flammable and non explosive.

It should have high thermal conductivity It should be easy to

handle

It should have low specific volume of vapour. It should have

high co efficient of performance

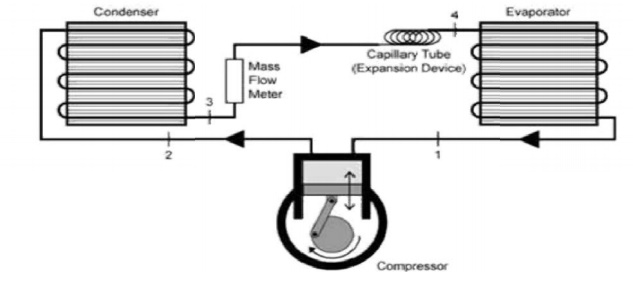

VAPOUR COMPRESSI ON REFRIGERATION SYSTEM

Construction:

This system consists o f a compressor, condenser, a receiver

tank, a n expansion valve and an evaporato r.

Compressor : Recipro cating compressors

generally used. For very big plants centrifugal compressor s directly

coupled with high speed rotating engi nes (gas turbine) are used.

For very big

plantsC entrifugal

compressors directly coupled

with high speed rotating engines (gas turbine) are used

Condenser : It is a coil of tubes made

of copper.

Receiver tank: It is the reservoir of

liquid refrigerant.

Expansion Valve: Thi s is

a throttle valve. High pressure refrigerant is made to flow at a

controlled rate through this valve.

Evaporator : It is the actual cooler

and kept in the space to be cooled. The evaporator is a coil of tubes

made of copper

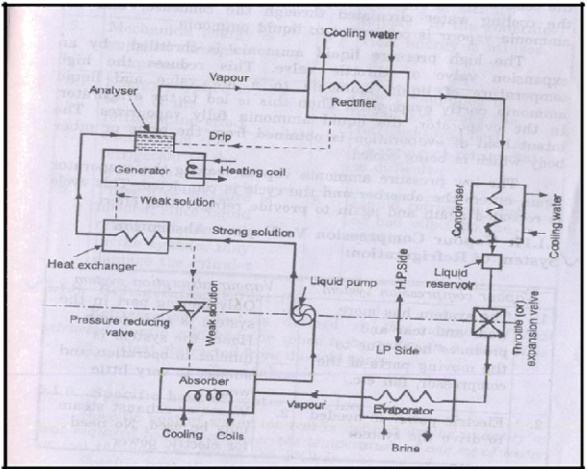

VAPOUR ABSORPTION REFRIGERATION SYSTEM:

Construction:

The vapour absorption system consists of a condenser, an

expansion valve and an evaporator.

They perform the same as t hey do

in vapour compression method.

In addition to these, this system has an absorber, a heat

exchanger, an analyser and a rectifier.

Working:

•

Dry ammonia vapour at low pressure passes in to

the absorber from the evaporator.

•

In the absorber the d ry ammonia vapour is

dissolved in cold water and strong solution of ammonia is formed.

•

Heat evolved during the absorption of ammonia is

removed by cir culating cold water through the coils kept in the absorber.

The highly concentrated ammonia (known as Aqua Ammonia) is

then pumped by a pump to generator through a heat exchanger.

•

In the heat exchanger the strong ammonia solution

is heated by the h ot weak solution returning from the generator to the

absorber.

•

In the generator the w arm solution is further

heated by steam coils, gas or electricity

and the

ammonia vapour is driven out of solution.

• The boiling point of a mmonia is

less than that of water.

•

Hence the vapours le aving the generator are

mainly of ammonia.

•

The weak ammonia solution is left in the generator

is called weak aq ua.

• This weak

solution is returned to the absorber through the heat exchan ger.

•

Ammonia vapours le aving the generator may contain

some water vap our.

•

If this water vapour i s allowed to the condenser

and expansion valv e, it may freeze resulting in chocked f low.

•

Analyser and rectifier s are incorporated in the

system before condenser.

•

The ammonia vapour from the generator passes

through a series of trays in the analyser and ammonia is separated from water

vapour.

•

The separated water v apour returned to generator.

• Then the ammonia va pour passes

through a rectifier.

• The rectifier

resembles a condenser

and water vapour

still prese nt in

ammonia

vapour

condenses andd the condensate is returned to analyser.

•

The virtually pure am monia vapour then passes

through the condense r.

•

The

latent heat of

ammonia vapour is

rejected to the

cooling water circulated

through

the condenser and the ammonia vapour is condensed to liquid ammonia.

• The high

pressure liquid ammonia is throttled by an expansion v alve or throttle valve.

•

This reduces the high temperature of the liquid

ammonia to a low value and liquid ammonia partly evaporates.

•

Then this is led to the evaporator.

•

In the evaporator the liquid fully vaporizes.

•

The latent heat of evaporation is obtained from

the brine or other body which is being cooled.

•

The low pressure ammonia vapour leaving the

evaporator again enters the absorber and the cycle is completed.

•

This cycle is repeated again to provide the

refrigerating effect.

Applications

of refrigeration system:

·

Preservation of food items like vegetables,

milk and eggs.

·

Preservation of medicines.

·

Preservation of blood, tissues, etc.,

·

Preservation and cooling of cool drinks.

·

Preservation of chemicals (Chemical

industries)

·

Cooling of water.

·

Industrial and comfort airconditioning.

·

Processing of dairy products.

COMPARISON BETWEEN VAPOUR COMPRESSION & VAPOUR

ABSORPTION REFRIGERATION SYSTEMS:

Vapour

Compression System

1. This system has more wear and tear and produces more noise due to the moving

parts of the compressor.

2. Electric power is needed to drive the system

3. Capacity of the system drops rapidly with lowered

evaporator pressure

4. At partial loads performance is poor.

5. Mechanical energy is supplied through compressor

6. Energy supplied is ¼ to ½ of the refrigerating effect

7. Charging of the refrigerating to the system is easy

8. Preventive measure is needed, since liquid refrigerant

accumulated in the cylinder may damage to the cylinder

Vapour

Absorption System

1. Only moving part in this system is an aqua pump. Hence the

quieter in operation and less wear and tear

2. Waste of exhaust steam may be used. No need of electric

power

3. Capacity of the system decreases with the lowered

evaporative pressure, by increasing the steam pressure in generator.

4. At partial loads performance is not affected.

5. Heat energy is utilized

6. Energy supplied is about one and half times the

refrigerating effect

7. Charging of refrigerant is difficult

8. Liquid refrigerant has no bad effect on the system.

Related Topics