Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Production Flow Analysis

PRODUCTION FLOW ANALYSIS

This is

an approach to part family identification and machine cell formation that was

pioneered by J. Burbidge [6][R]. Production

flow analysis (PFA) is a method for identifying part families and

associated machine groupings that uses the information contained 011 production

route sheets rather than on part drawings. Work parts with identical or similar

routings are classified into part families. These families can then be used to

form logical machine cells in a group technology layout. Since PFA uses

manufacturing data rather than design data to identify part families, it can

overcome two possible anomalies that can occur in parts classification and

coding. First, parts whose basic geometries are quite different may

nevertheless require similar or even identical process routings. Second, parts

whose geornetries are quite similar may nevertheless require process routings

that are quite different.

The

procedure in production flow analysis must begin by defining the scope of the

study, which means deciding on the population of parts to be analyzed. Should

all of the parts in the shop be Included in the study, or should a

representative sample be selected for analysis! Once this decision is made,

then the procedure in PFA consists of the following steps:

Data collection. The minimum data needed in the

analysis are the part number and operation

sequence, which is contained in shop documents called route sheets or operation

sheets or some similar name. Each operation is usually associated with a

particular machine, so determining the operation sequence also determines the

machine sequence. Additional data. such as lot size, time standards, and annual

demand might be useful for designing machine cells of the required production

capacity.

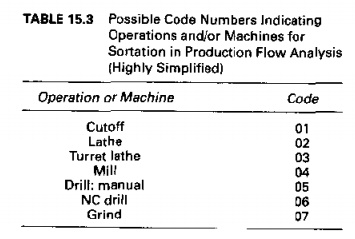

Soriation

of process routings. In this step, the parts are arranged into groups

according to the similarity of their process routings. To facilitate this step,

all operations or machines included in the shop are reduced to code numbers,

such as those shown in Table 15.3. For each part, the operation codes are

listed in the order in which they are performed. A sortation procedure is then

used to arrange parts into "packs," which are groups of parts with

identical routings. Some packs may contain only one part number, indicating the

uniqueness of the processing of that part. Other packs will contain many parts,

and these will constitute a part family.

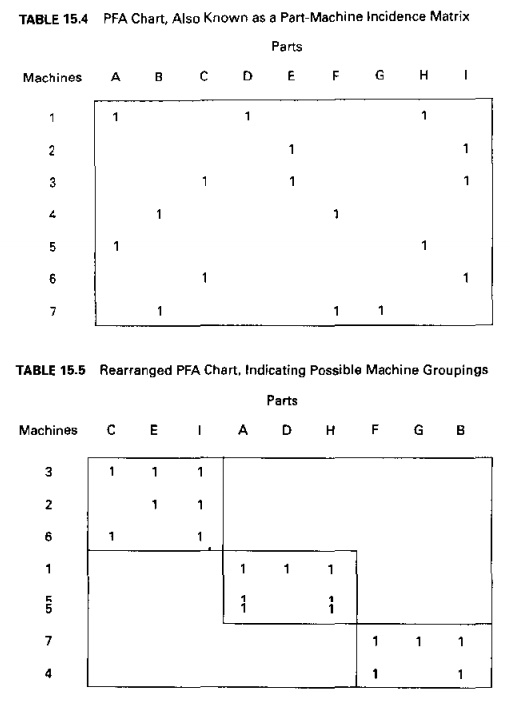

PFA

chart. The processes used for each pack are then displayed in a PFA chart, a simplified

example of which is illustrated in Table 15.4.1 The chart is a tabulation of the

process or machine code numbers for all of the part packs. In recent GT

literature [30], the PFA chart has been referred to as part-machine incidence matrix. In this matrix, the entries have a

value xii=1 or 0: a value of xij = 1 indicates that the

corresponding part i requires

processing on machine j, and X'I = 0

indicates that no processing of component i

is accomplished on machine j. For clarity of presenting the

matrix, the D's are often indicated as blank (empty) entries, as in our table.

Cluster

analysis. From the pattern of data in the PFA chart. related groupings are identified and rearranged into a new

pattern that brings together packs with similar machine sequences. One possible

rearrangement of the original PFA chart is shown in Table 15.5, where different

machine groupings are indicated within blocks. The blocks might be considered

as possible machine cells. It is often the case (but not in Table 15.5) that

some packs do not fit into logical groupings. These parts might be analyzed to

see if a revised process sequence can be developed that fits into one of the

groups. If not, these parts must continue to be fabricated through a

conventional process layout. In Section 15.6.1, we examine a systematic

technique called rank order clustering that can be used to perform

the cluster analysis.

TABLE 15.3

Possible Code Numbers indicating Operations and/or Machines for

Sortation in Production Flow Analysis (Highly Simplified)

The

weakness of production flow analysis is that the data used in the technique are

derived from existing production route sheets. In all likelihood, these route sheets have been prepared by

different process planners, and the routings may contain operations that are

non optimal, illogical, or unnecessary. Consequently, the final machine

groupings obtained in the analysis may be suboptimal. Notwithstanding this

weakness, PFA has the virtue of requiring less time than a complete parts

classification and coding procedure. This virtue is attractive to many firms

wishing to introduce group technology into their plant operations.

Related Topics