Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Parts Classification and Coding

PARTS CLASSIFICATION AND CODING

This is

the most time consuming of the three methods. In parts classification and coding, similarities among parts are

identified, and these similarities are related in a coding system. Two

categories of part similarities can be distinguished: (1) design attributes, which arc concerned with part characteristics

such as geometry, size, and material; and (2) manufacturing attributes, which consider the sequence of processing

steps required to make a part. While

the design and manufacturing attributes of a part are usually correlated, the

correlation is less than perfect. Accordingly, classification and coding

systems are devised to include both a part's design attributes and its

manufacturing attributes. Reasons for using a coding scheme include:

Design

retrieval. A designer faced with the task of developing a new

part can use a design retrieval system

to determine if a similar part already exists. A simple change in an existing

part would take much less time than designing a whole new part from scratch.

Automated

process planning. The part code for a new part can be used to search

for process plans for existing parts

with identical or similar codes

Machine

cell design. The part codes can be used to design machine cells

capable of producing all members of a

particular part family, using the composite part concept (Section 15.4.1).

To

accomplish parts classification and coding requires examination and analysis of

the design and/or manufacturing attributes of each part. The examination is

sometimes done

by

looking in tables to match the subject part against the features described and

diagrammed in the tables. An alternative and more-productive approach involves

interaction with a computerized classification and coding system, in which the

user responds to questions asked by the

computer. On the basis of the responses, the computer assigns the code number

to the part. Whichever method is used, the classification results in a code

number that uniquely identifies the part's attributes.

The

classification and coding procedure may be carried out on the entire list of

active parts produced by the firm, or some sort of sampling procedure may be

used to establish part families. For example, parts produced in the shop during

a certain time period could be examined to identify part family categories. The

trouble with any sampling procedure is the risk that the sample may be

unrepresentative of the population.

A number

of classification and coding systems are described in the literature [13],

[16], [31], and there are a number of commercially available coding packages.

However, none of the systems has been universally adopted. One of the reasons

for this is that a classification and coding system should be customized for it given company or industry. A

system that is best for one company may not be best for another company.

Features of Parts Classification and Coding

Systems

The

principal functional areas that utilize a parts classification and coding

system are design and manufacturing. Accordingly. parts classification systems

fall into one of three categories;

systems based

on part design attributes

systems

based on part manufacturing attributes

systems

based on both design and

manufacturing attributes

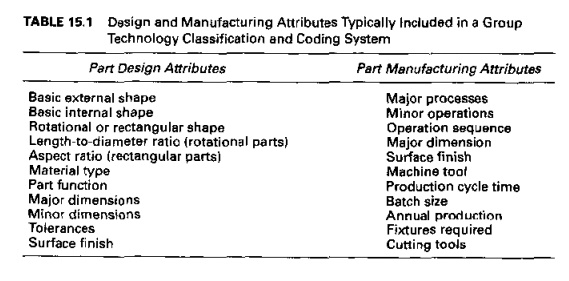

Table

15.1 presents a list of the common design and manufacturing attributes

typically included in classification schemes. A certain amount of overlap

exists between design and manufacturing attributes, since a part's geometry is

largely determined by the sequence of manufacturing processes performed on it.

In terms

of the meaning of the symbols in the code, there are three structures used in

classification and coding schemes:

hierarchical

structure, also known as a

monocode, in which the interpretation of each successive symbol depends on the value of the preceding symbols

Chain-type

structure, also known as a

polycode, in which the interpretation of each symbol in the sequence is always the same; it does not depend on

the value of preceding symbols

mixed-mode

structure. which is a

hybrid of the two previous codes

To

distinguish the hierarchical and chain-type structures, consider a two-digit

code number for a part, such as 15 or 25. Suppose the first digit stands for

the general shape of the part: 1 means the part is cylindrical (rotational),

and 2 means the geometry is rectangular.

In a hierarchical structure, the interpretation of the second digit depends on the value of the first digit. If preceded by 1, the 5 might indicate a length to diameter ratio; and if preceded by 2, the 5 indicates an aspect ratio between the length and width dimensions of the part. In the chain-type structure, the symbol 5 would have the same meaning whether preceded by 1 or 2. For example, it might indicate the overall length of the part. The advantage of the hierarchical structure is that in general. more information can he included in a code of a given number of digits.

The

number of digits in the code can range from 6 to 30. Coding schemes that

contain only design data require fewer digits. perhaps 12 or fewer. Most modem

classification and coding systems include both design and manufacturing data,

and this usually requires 2030 digits. This might seem like too many digits fur

a human reader to easily comprehend, but it must be remembered that most of the

data processing of the codes is accomplished by computer. for which a large

number of digits is of minor concern

Examples of

Parts Classification and Coding Systems

Some of

the important systems (with emphasis on those in the United States) include: the

Opitz classification system, which is nonproprietary; the Brisch System (Brisch-Birn,

Inc.); CODE (Manufacturing Data Systems. lnc.]: CUTPLAN (Metcut Associates);

DCLASS (Brigham Young University): Multi-Class (OIR: Organization for

Industrial Research);and Part Analog System (Lovelace. Lawrence & Co., Inc.). Reviews of these

systems and others can be found in [161 and [23].

In the

following. we discuss two classification and coding systems: the Opitz System

and Multi-Class. The Opitz system is 0' interest because it was one of the

first published classification and coding schemes for mechanical parts [31]

(Historical Note 15.1) and is still widely used. MultiClass is a commercial

product offered by the Organization for Industrial Research (OIR)

Opitz

Classification System. This system was developed by H. Opitz of the

University of Aachen in Germany. It represents one of the pioneering efforts in

group technology and is probably the best known, if not the most frequently

used, of the parts classification and coding systems. It is intended for

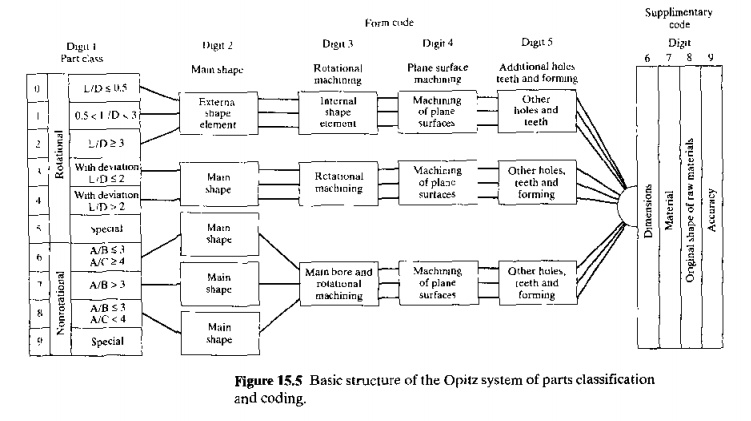

machined parts. The Opitz coding scheme uses thc following digit sequence:

12345 6789 ABCD

The basic

code consists of nine digits, which can be extended by adding four more digits.

The first nine arc intended to convey both design and manufacturing data. The

interpretation of the first nine digits is defined in Figure 15.5. The first

five digits, 12345, are called the form

code. It describes the primary design attributes of the part, such as

external shape (e.g., rotational vs.

rectangular) and machined features (e.g., holes, threads, gear teeth, etc.].

The next four digits, 6789, constitute the supplementary

code, which indicates some of the attributes that would be of use in

manufacturing (e.g., dimensions, work material, starting shape, and accuracy).

The extra four digits, ABCD, are referred to as the secondary code and are intended to identify the production

operation type and sequence. The secondary code can be designed by the user

firm to serve its own particular needs.

The

complete coding system is too complex to provide a comprehensive description

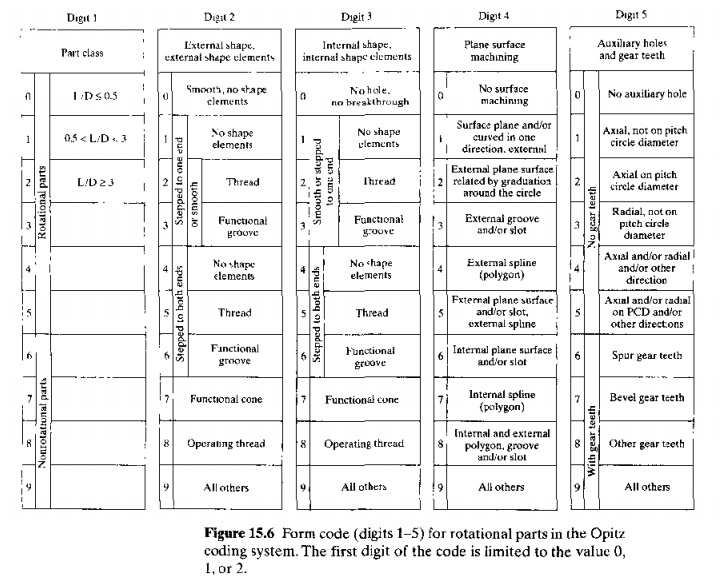

here. Opitz wrote an entire book on his system [31]. However, to obtain a general

idea of how it works, let us examine the form code consisting of the first five

digits. defined generally in Figure 15.5. The first digit identifies whether

the part is rotational or nonrotational.1t also describes the general shape and

proportions of the part. We limit our survey here to rotational parts

possessing no unusual features, those with first digit values of O, 1,

Or 2. For

this etas, of work parts, the coding of the first five digits is defined in

Figure 15,6. Consider the following example to demonstrate the coding of a

given part.

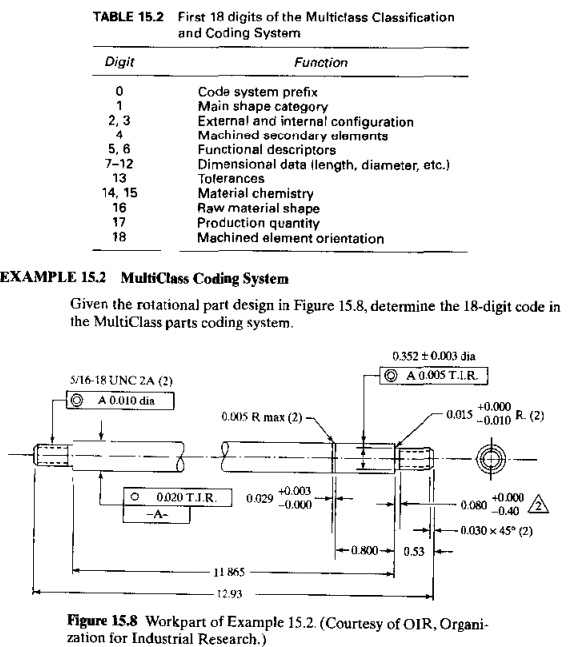

EXAMPLE

15.1 Opitz Part Coding System

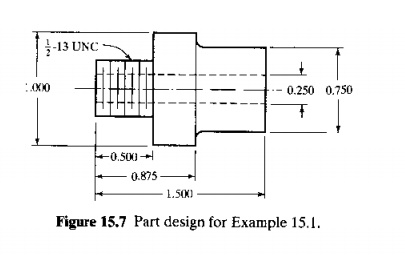

Given the

rotational part design in Figure 15.7, determine the form code in the Opitz

parts classification and coding system

Solution:

With reference to Figure 15.6, the

fivedigit code is developed as follows:

Lengthtodiameter

ratio, LID = 1.5 Digit 1 = 1

External

shape: stepped on both ends with screw

thread on one end Digit 2 = 5

Internal

shape: part contains a throughhole Digit 3 ==

1

Plane

surface machining: none Digit 4 == 0

Auxiliary

holes, gear teeth, etc.: none Digit 5 =

0

The form

code in the Opitz system is 15100.

MultiClass.

MultiClass

is a classification and coding system developed by the Organization for

Industrial Research (OIR). The system is relatively flexible, allowing the user

company to customize the classification and COlling scheme 10 a large extent to

fit its own products and applications. Multi Class can be used for a variety of

different types of manufactured items, including machined and sheer metal

parts, tooling, electronics, purchased

parts, assemblies

and subassemblies, machine tools, and other elements.

Up to nine different types of components

can be included within a single MultiClass software structure

MultiClass uses a hierarchical or decision-tree coding

structure in which the succeeding digits depend

on values of the previous digits. In the application of the system, a series of menus, pick lists,

tables, and other interactive prompting

routines are used to code the

part. This helps to organize and provide discipline to the coding procedure.

The

coding structure consists of up to 30 digits. These are divided into two

regions, one provided by GIR, and the second designed by the user to meet specific needs

and requirements. A prefix precedes the code number and is used to identify the

type of part (e.g., a prefix value of 1 indicates machined and sheet metal

parts). For a machined part, the coding for the first 18 digit positions (after

the prefix) is summarized in Table 15.2.

TABLE 15.2 First 18 digits of the Multiclass

Classification and Coding System

Digit Function

o Code

system preflx

1 Main

shape category

2,3 External

and internal configuration

4 Machined

secondary elements

5,6 Functional

descriptors

712 Dimensional data !length, diameter, etc.)

13 Tolerances

14,15 Material

chemistry

Raw

material shape

Production quantity

Machined

element orientation

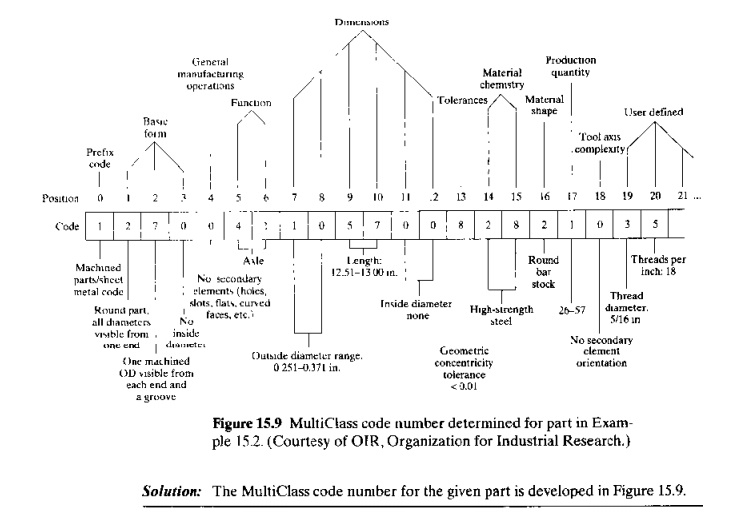

EXAMPLE 15.2 MuitiClass

Coding System

Given the

rotational part design in Figure 15.8, determine the IS digit code in the

MultiClass parts coding system.

Related Topics