Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Group Technology: Part Families

PART FAMILIES

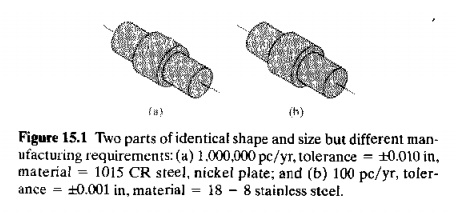

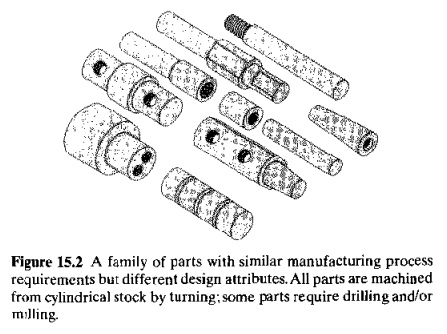

Apart family is a collection of parts that are

similar either because of geometric shape and size or because similar processing steps are required in their

manufacture. The parts within a family are different, but their similarities are

close enough to merit their inclusion as members of the part family. Figures

15.1 and 15.2 show two different part families. The two parts in Figure 15.1

are very similar in terms of geometric design, but quite different in terms of

manufacturing because of differences in tolerances, production quantities, and

material. The ten parts shown in Figure 15.2 constitute fl. part family in

manufacturing, but their different geometries make them appear quite different

from a design viewpoint.

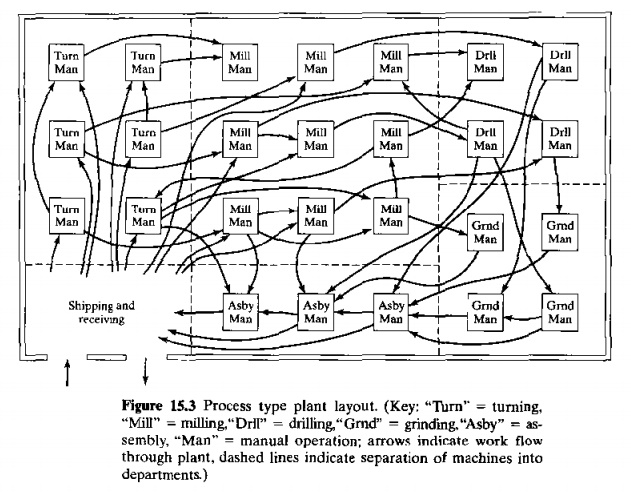

One of

the important manufacturing advantages of grouping workparts into families can

be explained with reference to Figures 15.3 and 15.4. Figure 15.3 shows a

process

type

plant layout for batch production in a machine shop. The various machine tools

are arranged by

function. There is a lathe department, milling machine department, drill press

department, and so all. To machine a given part, the workpiece must be

transported between departments, with perhaps the same department being visited

several times. This results in a significant amount of material handling, large

in-process inventory, many machine setups, long manufacturing lead times, and

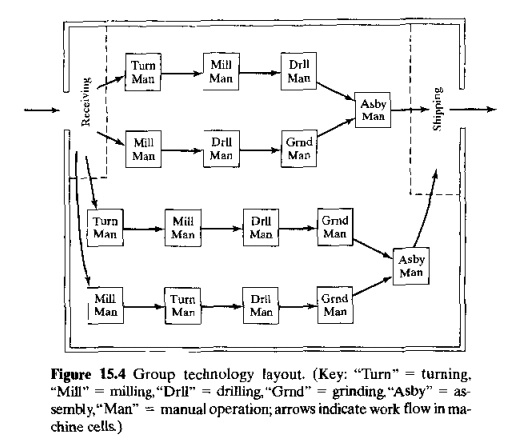

high cost. Figure 15.4 shows a production shop of equivalent capacity, but the

machines are arranged into cells. Each cell is organized to specialize in the

production of a particular part family. Advantages of reduced work-piece handling yield lower setup times,

fewer setups (in some cases, no setup changes are necessary), less in-process

inventory, and shorter lead times.

The

biggest single obstacle in changing over to group technology from a

conventional production shop is the problem of grouping the parts into

families. There are three general methods for solving this problem. All three

are time consuming and involve the analysis of much data by properly trained

personnel. The three methods are; (1) visual inspection, (2) parts

classification and coding, and (3) production flow analysis. Let us provide a

brief description of the visual inspection method and then examine the second

and third methods in more detail.

The visual inspection method is the least sophisticated and least expensive method. It involves the classification of parts into families by looking at either the physical parts or their photographs and arranging them into groups having similar features. Although this method is generally considered to be the least accurate of the three. one of the first major-success stories of GT in the United States made the changeover using the visual inspection method. This was the Langston Division of Harris Intertype in Cherry Hill, New Jersey

Related Topics