Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Cellular Manufacturing

CELLULAR

MANUFACTURING

Whether

part families have been determined by visual inspection. parts classification

and coding, or production flow analysis, there is advantage in producing those

parts using group technology machine cells rather than a traditional process type

machine layout. When the machines are grouped. the term cellular manufacturing

is used to describe this work organization. Cellular

manufacturing is an application of group technology in which dissimilar

machines or processes have been aggregated into cells, each of which is

dedicated to the production of a part or product family or a limited group of

families. The typical objectives in cellular manufacturing are similar to those

of group technology:

To

shorten manufacturing lead times, by reducing setup, workpart

handling, waiting times, and batch

sizes

To reduce

work-in-process inventory. Smaller batch sizes and shorter lead times reduce

work-in-process.

To improve

quality. This is

accomplished by allowing each cell to specialize in producing a smaller number

of different parts. This reduces process variations.

To

simplify production scheduling. The similarity among parts in the

family reduces the complexity of

production scheduling. Instead of scheduling parts through a sequence of machines

in a process-type shop layout, the parts are simply scheduled though the cell.

To reduce

setup times. This is accomplished by using group tooling (cutting tools,

jigs, and fixtures) that have been designed to process the part family,

rather than part tooling, which is designed for an individual part. This

reduces the number of individual tools required as well as the time to change

tooling between parts.

Additional

reasons for implementing cellular manufacturing are given in Table 15.7. In

this section, we consider several aspects of cellular manufacturing and the

design of machine ceils.

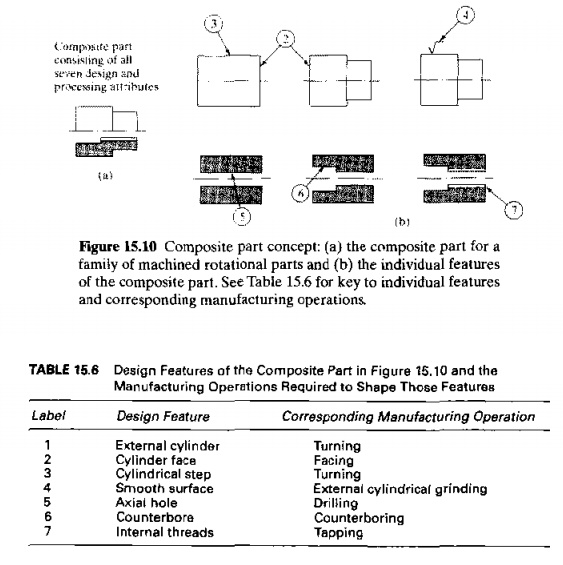

Composite Part

Concept

Part

families are defined by the fact that their members have similar design and/or

manufacturing features. The composite part concept takes this part family

definition to its logical conclusion. It conceives of a hypothetical part, a composite part for a given family, which

includes all of the design and manufacturing attributes of the family. In

general. an individual part in the family will have some of the features that

characterize the family but not all of them. The composite part possesses all

of the features.

There is

always a correlation between part design features and the production operations

required 10 generate those features. Round holes are made by drilling,

cylindrical shapes are made by turning, flat surfaces by milling, and so on. A

production cell designed for the part family would include those machines

required to make the composite part. Such a cell would be capable of producing

any member of the family, simply by omitting those operations corresponding to

features not possessed by the particular part. The cell would also be designed

to allow for size variations within the family as well as feature variations.

To

illustrate, consider the composite part in Figure 15.1O(a).1l represents a

family of rotational parts with features defined in Figure 15.1O(b). Associated

with each feature is a certain machining operation as summarized in Table 15.6.

A machine cell to produce this

part

family would be designed with the capability to accomplish all seven operations

required to produce the composite pan (the last column in the table). To

produce a specific member of the family, operations would be included to

fabricate the required features of the part. For parts without all seven

features, unnecessary operations would simply be omitted. Machines, fixtures,

and tools would be organized for efficient flow of work-parts through the cell,

In

practice, the number of design and manufacturing attributes is greater than seven,

and allowances must be made for variations in overall size and shape of the

parts in the family. Nevertheless, the composite part concept is useful for

visualizing the machine cell design problem.

Machine Cell Design

Design of

the machine cell is critical in cellular manufacturing. The cell design determines

to a great degree the performance of the cell. In this subsection, we discuss

types of machine cells, cell layouts, and the key machine concept.

Types

of Machine Cells and Layouts. GT manufacturing cells can be

classified according to the number of machines and the degree to which the material

flow is mechanized between machines. In our classification scheme for

manufacturing systems (Section 13.2), all GT cells are classified as type X in

terms of part or product variety (Section 13.2.4, Table 13.3). Here we identify

four common GT cell configurations (with system type identified in parenthesis

from Section 13.2):

single

machine cell (type I M)

group machine cell with manual handling

(type n M generally, type III M less common)

group machine

cell with semi-integrated handling (type II M generally, type III M less

common)

flexible

manufacturing cell or flexible manufacturing system (type IT A generally, type

III A less common)

As its

name indicates, the single machine cell

consists of one machine plus supporting fixtures and tooling. This type of cell

can be applied to work-parts whose attributes allow them to be made on one

basic type of process, such as turning or milling. For example, the composite part of Figure 15.10 could be produced

on a conventional turret lathe, with the possible exception of the cylindrical

grinding operation (step 4)

The group machine cell with manual handling

is an arrangement of more than one machine used collectively to produce one or

more part families. There is no provision for mechanized parts movement between

the machines in the cell. Instead, the human operators who run the cell perform

the material handling function. The cell is often organized into a U shaped

layout, as shown in Figure 15.11. This layout is considered appropriate when

there is variation in the work flow among the parts made in the cell. It also

allows the multifunctional workers in the cell to move easily between machines

[29].

The group

machine cell with manual handling is sometimes achieved in a conventional

process type layout without rearranging the equipment. This is done simply by

assigning certain machines to be included in the machine group and restricting

their work to specified part families. This allows many of the benefits of

cellular manufacturing to be achieved without the expense of rearranging

equipment in the shop. Obviously, the material handling benefits of OT are

minimized with this organization.

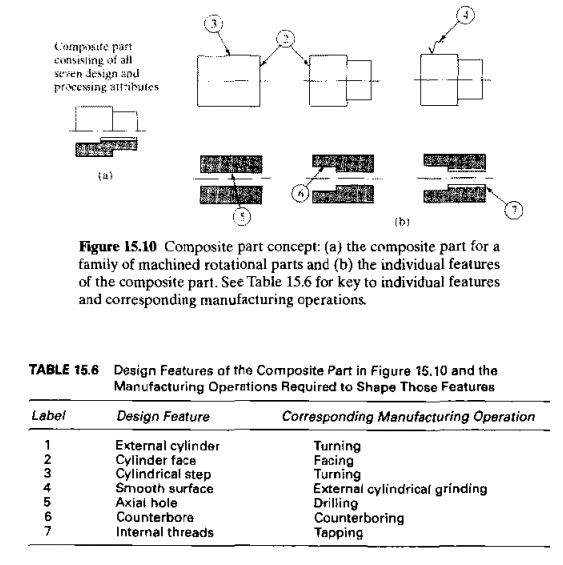

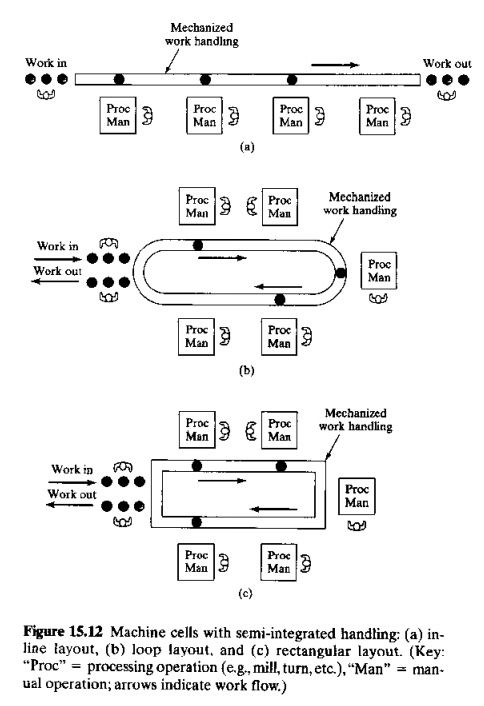

The group machine cell with semi integrated

handling uses a mechanized handling system, such as a conveyor, to move

parts between machines in the cell. The flexible

manufacturing system (FMS) combines a fully integrated material handling

system with automated processing stations. The FMS is the most highly automated

of the group technology machine cells. The following chapter is devoted to this

form of automation, and we defer discussion till then.

A variety

of layouts are used in GT cells, The U-shape, as in Figure 15.11, is a popular configuration

in cellular manufacturing. Other GT layouts include inline, loop, and

rectangular, shown in Figure 15.12 for the case of semi integrated handling.

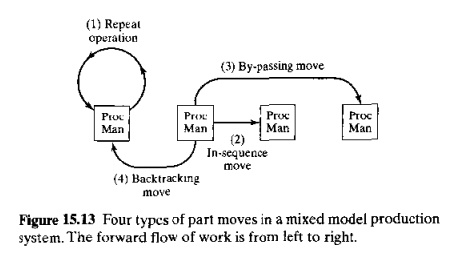

Determining

the most appropriate cell layout depends on the routings of parts produced in

the cell. Four types of part movement can be distinguished in a mixed model

part production system. They are illustrated in Figure 15.13 and are defined as

follows, where the forward direction of work flow is defined as being from left

to right in the figure:(l) repeat

operation, in which a consecutive operation is carried out on the same

machine, so that the part does not

actually move; (2) in-sequence move,

in which the part moves from the current machine to an immediate neighbor in

the forward direction; (3) bypassing

move, in which the part moves forward from the current machine to another

machine that is two or more machines ahead; and (4) backtracking move, in which the part moves from the current machine

in the backward direction to another machine.

When the

application consists exclusively of in sequence moves, then an inline layout is

appropriate. A V-shaped layout also works well here and has the advantage of

closer interaction among the workers in the cell. When the application includes

repeated operations, then multiple stations (machines) are often required. For

cells requiring bypassing moves, the U-shape layout is appropriate. When

backtracking moves are needed, a loop or rectangular layout is appropriate to

accommodate recirculation of parts within the cell. Additional factors that

must be accounted for in the cell design include:

Quantity

of work to be done by the cell. This includes the number of parts

per year and the processing (or

assembly) time per part at each station. These factors determine the workload

that must be accomplished by the cell and therefore the number of machines that

must be included, as well as total operating cost of the cell and the

investment that can be justified .

Part

size, shape, weight, and other physical attributes. These

factors determine the size and type

of material handling and processing equipment that must be used.

Key

Machine Concept. In some respects, a GT machine cell operates like a

man.

ual

assembly line (Chapter 17), and it is desirable to spread the workload evenly

among the machines in the cell as much as possible. On the other hand, there is

typically a certain rnachine in a cell (or perhaps more than one machine in a

large cell) that is more expensive to operate than the other machines or that

performs certain critical operations in the plant This machine is referred to

as the key machine. It is important

that the utilization of this key machine be high. even if it means that the

other machines in the cell have relatively low utilization. The other machines

are referred to as supporting machines,

and they should be organized in the cell to keep the key machine busy. In a

sense, the cell is designed so that the key machine becomes the bottleneck in the

system.

The key

machine concept is sometimes used to plan the GT machine cell. The approach is

to decide what parts should be processed through the key machine and then

determine what supporting machines are required to complete the processing of

those parts.

There are

generally two measures of utilization that are of interest in a GT cell: the

utilization of the key machine and the utilization of the overall cell. The

utilization of the key machine can be measured using the usual definition

(Section 2.4.3). The utilization of each of the other machines can also be

evaluated similarly. The cell utilization is obtained by taking a simple

arithmetic average of all the machines in the cell. One of the exercise

problems at the end of the chapter serves to illustrate the key machine concept

and the determination of utilization

Related Topics