Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Application Considerations in Group Technology

APPLICATION CONSIDERATIONS IN GROUP TECHNOLOGY

In this

section, we consider how and where group technology is applied, and we report

on the results of a survey of industry about cellular manufacturing in the

United States [38]

Applications

of Group Technology

In our

introduction to this chapter, we defined group technology as a

"manufacturing philosophy." GT is not a particular technique,

although various tools and techniques, such as parts classification and coding

and production flow analysis, have been developed to help implement it. The

group technology philosophy can be applied in a number of areas, Our discussion

focuses on the two main areas of manufacturing and product design.

Manufacturing Applications. The most

common applications of GT are in manufacturing. And the most common application

III manufacturing involves the

formation of cells of one kind or another, Not all companies rearrange machines

to form cells. There are three ways in which group technology principles can be

applied in manufacturing [24]:

Informal scheduling and routing of similar parts

through selected machines. This approach

achieves setup advantages. but no formal part families are defined, and no

physical rearrangement of equipment is undertaken.

Virtual

machine cell This approach involves the creation of part families and dedication

of equipment to the manufacture of these part families, but without the

physical rearrangement of machines into formal cells. The machines in the

virtual cell remain in their original locations in the factory. Use of virtual

cells seems to facilitate the sharing of machines with other virtual cells

producing other part families [25J.

Formal machine cells. This is

the conventional GT approach in which a group of dissimilar machines are

physically relocated into a cell that is dedicated to the production of one or

a limited set of parts families (Section 15.4.2). The machines in a formal machine

cell are located in close proximity to minimize part handling, throughput name.

setup time, and work-in-process.

Other GT

applications in manufacturing include process planning (Chapter 25), family

tooling, and numerical control (NC) part programs. Process planning of new

parts can be facilitated through the identification of part families. The new

part is associated with an existing part family. and generation of the process

plan for the new part follows the routing of the other members of the part

family. This is done in a formalized way through the use of parts

classification and coding. The approach is discussed in the context of auto

mated process planning (Section 25.2.1).

In the

ideal, all members of the same part family require similar setups, tooling, and

fixturing. This generally results in a reduction in the amount of tooling and fixturing

needed Instead of determining a special tool kit for each part, a tool kit is

developed for each part family. The concept of a modular fixture can often be exploited, in which a common base

fixture is designed and adaptations are made to switch between different parts

in the family

A similar

approach can be applied in NC part programming. Called parametric programming. [28], it involves the preparation of a

common NC program that covers the entire

part family. The program is then adapted for individual members of the family by inserting dimensions and other

parameters applicable to the particular part. Parametric programming reduces

both programming time and setup time.

Product

Design Applications. The application of group technology in product design is

found principally in the use of design retrieval systems that reduce part

proliferation in the firm. It has been estimated that a company's cost to

release a new part design ranges between $2000 and $12.000 [37]. In a survey of

industry reported in [36], it was concluded that in about 20% of new part

situations, an existing part design could be used. In about 4(J% of the cases,

an existing part design could be used with modifications, The remaining cases

required new part designs. If the cost savings for a company generating 1000

new part designs per year were 75% when an existing part design could be used

(assuming that there would still be some cost oftime associated with the new

part for engineering analysis and design retrieval) and 50% when an existing

design could be modified, then the total annual savings to the company would

lie between $700,000 and $4,200,000, or 35% of the company's total design

expense due to part releases. The kinds of design savings described here

require an efficient design retrieval procedure. Most part design retrieval

procedures lin: based on

parts classification and coding systems (Section 15.2).

Other

design applications of group technology involve simplification and

standardization of design parameters, such as tolerances inside radii on

corners, chamfer sizes on outside edges, hole sizes, thread sizes, and so

forth. These measures simplify design procedures and reduce part proliferation.

Design standardization also pays dividends in manufacturing by reducing the

required number of distinct lathe tool nose radii, drill sizes, and fastener

sizes. There is also a benefit in terms of reducing the amount of data and

information that the company must deal with. Fewer part designs, design

attributes, tools, fasteners, and so on mean fewer and simpler design

documents, process plans, and other data records.

Survey of Industry Practice

A number

of surveys have been conducted to learn how industry implements cellular manufacturing

[24], [36], [38J. The surveyed companies represent manufacturing industries,

such as machinery, machine tools, agricultural and construction equipment,

medical equip

ment.

weapons systems. diesel engines. and piece parts. Processes grouped

into cells in the companies

included machining, joining

and assembly, finishing, testing,

and metal forming

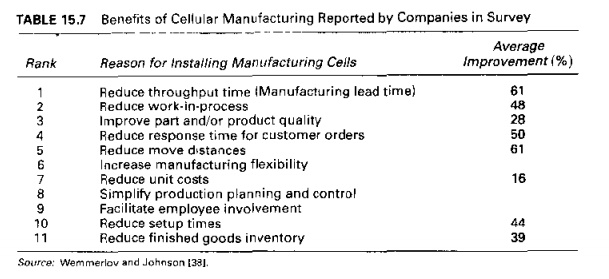

Companies in the survey were asked to report their reasons

for establishing machine cells

and the benefits they enjoyed from

implementing cellular manufacturing in the operations. Results are listed in

Table 15.7. The reasons are listed in the relative order of importance as

indicated by the companies participating in the survey. We also list the

average percentage improvement reported by the companies, rounded to the

nearest whole percentage point. Reasons 6, 8, and 9 are difficult to evaluate

quantitatively, and no percentage improvements are listed in these cases.

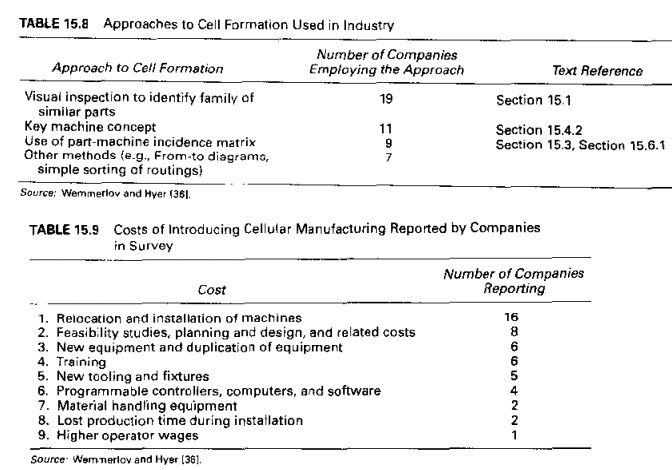

One of

the questions considered in the 1989 survey [36] was: What are the approaches

used by companies to form machine cells? The results are listed in Table 15.8. The most

common approach consisted of visually grouping similar parts with no

consideration given to existing routing information and no parts classification

and coding. The use of a part-machine incidence matrix was not widely reported,

perhaps because the formal algorithms for reducing this matrix, such as rank

order clustering (Section 15.6.1) were not

widely known at the time of the survey

Companies

also reported costs associated with implementing cellular manufacturing. The

reported cost categories are listed in Table 15.9 together with the number of

companies reporting the cost. No numerical estimates of actual costs are

provided in the report.

Topping

the list was the expense of equipment relocation and installation. Most of the

companies responding to the survey had implemented cellular manufacturing by

moving equipment in the factory rather than by installing new equipment to form

the cell.

Related Topics