Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Group Technology and Cellular Manufacturing

Quantitative Analysis in Cellular Manufacturing

QUANTITATIVE ANALYSIS IN CELLULAR MANUFACTURING

A number

of quantitative techniques have been developed to deal with problem areas in

group technology and cellular manufacturing. In this section, we consider two

problem areas: (1) grouping parts and machines into families, and (2) arranging

machines in a GT cell. The first problem area has been and still is an active

research area, and several of the more significant research publications are

listed in our references . The technique we

describe in the current section for salving the part and machine grouping

problem is rank order clustering . The second problem area has also been

the subject of research, and several reports are listed in the references.

Grouping Parts and Machines by Rank Order

Clustering

The

problem addressed here is to determine how machines in an existing plant should

be grouped into machine cells. The problem is the same whether the cells are

virtual or formal (Section 15.5.1 ).It is basically the problem of identifying

part families. By identifying part families, the machines required in the cell

to produce the part family can be properly selected. As previously discussed, the

three basic methods to identify part families are (1) visual inspection, (2)

parts classification and coding, and (3) production flow analysis.

The rank order clustering technique. first

proposed by King [26J, is specifically applicable in production flow analysis.

It is an efficient and easy-to-use algorithm for grouping machines into cells.

In a starting part machine incidence matrix that might be compiled to document

the part routings in a machine shop (or other job shop), the occupied locations

in the matrix are organized in a seemingly random fashion. Rank order

clustering works by reducing the part machine incidence matrix to a set of diagonalized

blocks that represent part families and associated machine groups. Starting

with the initial part machine incidence matrix. the algorithm consist, of the

following steps:

In each

row of the matrix. read the series of ls and G's (blank entries = D's) from left to fight as a

binary number. Rank the rows in 01 del uf

decreasing value. In case of a tie, rank the rows in the same order as they

appear in the current matrix

Numbering

from top to bottom, is the current order of rows the same as the rank order

determined in the previous step? If yes, go to step 7, If no, go to the following step.

3,

Reorder the rows in the part-machine incidence matrix by listing them in

decreasing rank order, starting from the top

In each

column of the matrix. read the series of I 's and O's (blank entries = (j's) from top to bottom as a

binary number. Rank the columns in order of decreasing value, In case of a tie.

rank the columns in the same order as they appear in the current matrix.

Numbering

from left to right, is the current order of columns the same as the rank order

determined in the previous step? If yes. go to step 7. If no. go to the

following step.

Reorder

the columns in the part-machine incidence matrix by listing them in decreasing

rank order, starting with the left column. Go to step I.

7 Stop

For

readers unaccustomed to evaluating binary numbers in steps 1 and 4, it might be

helpful to convert each binary value into its decimal equivalent (e.g., the

entries in the first row of the matrix in Table 15.4 are read as 100100(10).

This is converted into its decimal equivalent as follows: lx28 + Ox2' + Ox2b + 1x25 + Ox24 + Ox23 + Ox22

+ Ix2] + Ox2° = 256 + 32 + 2 = 290. It should be mentioned that decimal

conversion becomes impractical for the large numbers of parts found in

practice, and comparison of the binary numbers is preferred

EXAMPLE 15.3 Rank

Order Clustering Technique

Apply the

rank order clustering technique to the part-machine incidence matrix in Table

15.4

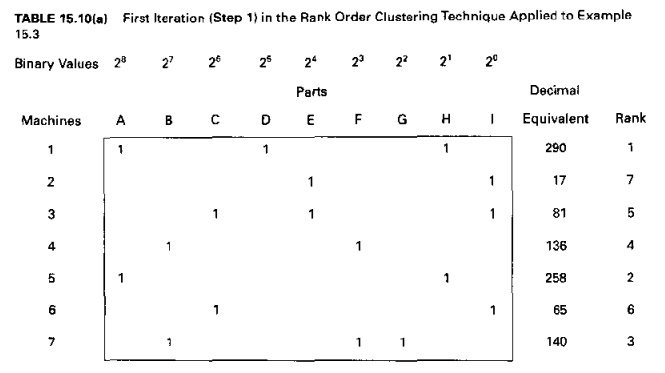

Solution: Step I consists of reading the

series of 1's and D's in each row as a binary number. We have done this in

Table 15.10(a). converting the binary value for each row to its decimal

equivalent. The values are then rank ordered in the far right-hand column. In

step 2. we see that the row order is different from the starting matrix. We

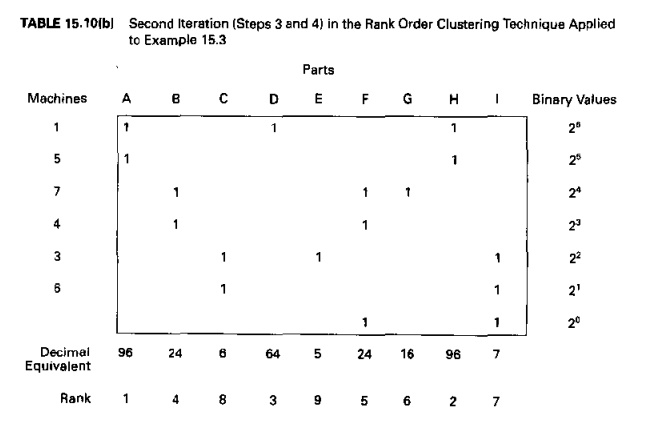

therefore reorder the rows in step 3. In step 4, we read the series of I's and

D's in each column from top to bottom as a binary number (again we have

converted to the decimal equivalent, and the columns are ranked in order of

decreasing value, as shown in Table 15.10(b).ln step 5, we see that the column

order is different from the preceding matrix. Proceeding from step 6 back to

steps 1 and 2, we see that a reordering of the columns provides a row order

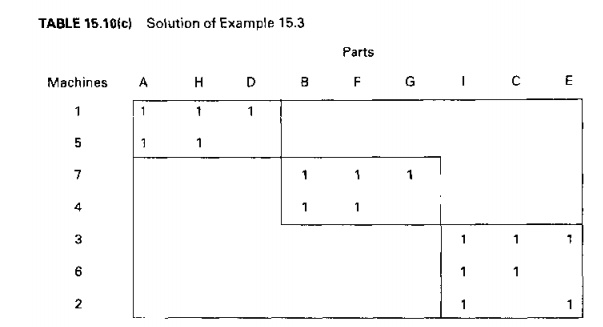

that is in descending value. and the algorithm is concluded (step 7). The final

solution is shown in Table 15.10(c), A

close comparison of this solution with Table 15,5 reveals that they are the

carne part-machine groupings,

In the

example problem, it was possible to divide the parts and machines into three

mutually exclusive part-machine groups. This represents the ideal case because

the part families and associated machine cells are completely segregated.

However, it is not uncommon for there to be an overlap in processing

requirements between machine groups That is, a given part type needs to be processed

by more than one machine group. Let us illustrate this case and how the rank

order clustering technique deals with it in the following example.

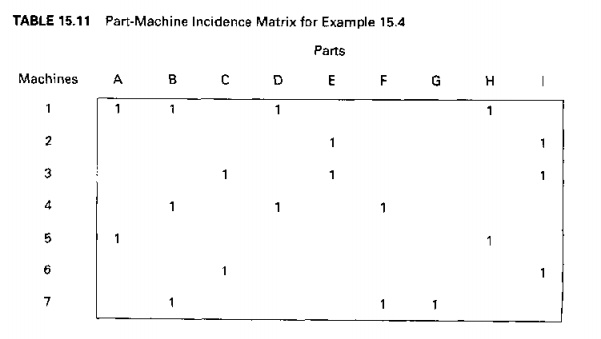

EXAMPLE 15.4 Overlapping Machine Requirements

Consider the part-machine incidence matrix in Table 15.11. This is the same as the original part-machine incidence matrix in Table 15.4 except that part B requires

processing

on machines 1.4, and 7 (1 is the additional machine) and part D now requires

processing on machines 1 and 4 (4 is the additional machine). Use the rank

order clustering technique to arrange parts and machine into groups.

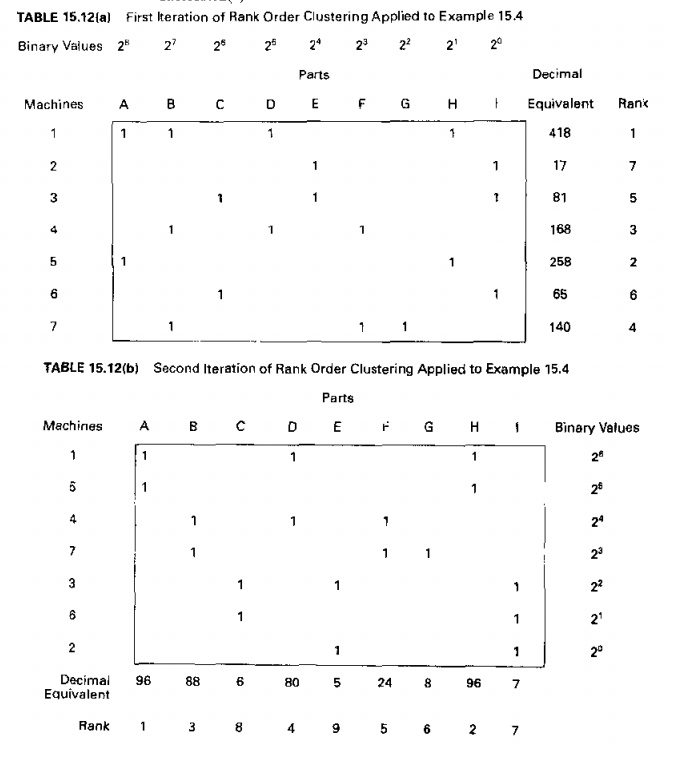

Solution: The rank order clustering technique

converges to a solution in two iterations, shown in Tables 15.12(a) and

15.l2(b), with the final solution shown in Table1.'l.12(c).

Parts B

and D could be included in either of two machine groups. Our solution includes

them in machine group (1.7); however, they must also be processed in machine

group (1. 5)

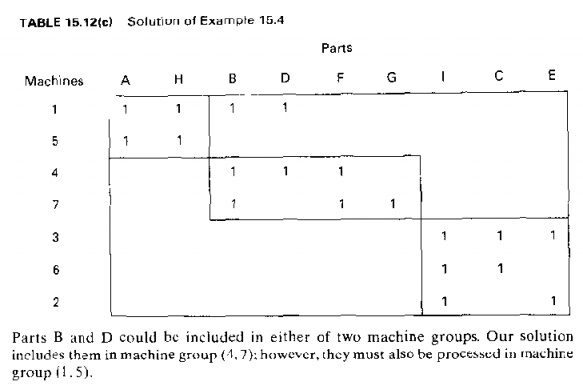

King [26]

refers to the matrix elements

Bl and Dj (parts Band D

processed on machine in Table 15.l2(c) as exceptional elements,

He recommends that they each he

replaced with an asterisk (*) and treated

as zeros when applying the rank order clustering technique. The effect

of' this approach in our

example problem would

be to organize the machines

exactly as we have done in our final solution in Table 15.12(c).Another way of

dealing with the overlap h simply to duplicate the machine that is used by more

than one part family. In Example 15.4, this would mean that two machines of

type 1 would be used in the two censTbe result of this duplication is shown in

the matrix of Table 15.13.where the two machines are identified as l a and j b.

Of course. there may be economic considerations that would inhibit the machine

redundancy.

Other

approaches to the problem of overlapping machines, attributed to Burbidge [26J,

include: (1) change the routing so that all processing can be accomplished in

the pn. mary machine group. (2) redesign the part to eliminate the processing

requirement outside the primary machine group, and (3) purchase the part from

an outside supplier.

Arranging

Machines in 8 GT Cell

After

part-machine groupings have been identified by rank order clustering or other

method. the next problem is to organize the machines into the most logical

arrangement. Let us describe two simple yet effective methods suggested by Hollier

[17]. Both methods use data contained in From-To charts (Section 10.6.1) and

are intended to arrange the machines in an order that maximizes the proportion

of in-sequence moves within the cell

Hollier

Method 1. The first method uses the sums of flow "From" and

"To" each machine in the cell. The method

can be outlined as follows:

Develop

the From-To chart from part routing data. The data contained in

the chart indicates numbers of part moves between the machines (or

workstations) in the cell. Moves into and out of the cell are not included in

the chart.

Determine

the “From” and “TO” sums for each

machine. This is accomplished by summing

all of the "From" trips and "To" trips for each machine (or

operation). The "From" sum for a machine is determined by adding the entries in the

corresponding row, and the "To" sum is found by adding the entries in the

corresponding column.

Assign

machines to the cell hosed on minimum

"From" or "To" sums. The machine having the smallest sum is selected. If the minimum value is a

"To" sum, then the machine is placed at the beginning of the

sequence. If the minimum value is a "From" sum, then the machine is

placed at the end of the sequence. TIe breaker rules:

If a tie

occurs between minimum "To" sums or minimum "From" sums,

then the machine with the minimum "From/To" ratio is selected.

If both

"To" and "From" sums are equal for a selected machine,it is

passed over and the machine with the next lowest sum is selected.

If a

minimum "To" sum is equal to a minimum "From" sum, then

both machines are selected and placed at the beginning and end of the sequence,

respectively.

Reformat the From-To chan. After

each machine has been selected, restructure the From-To chart by

eliminating the row and column corresponding to the selected machine and recalculate the

"From" and "To" sums. Repeat steps 3 and 4 until all

machines have been assigned.

EXAMPLE 15.5 Group

Technology Machine Sequence using

Hollier Method 1

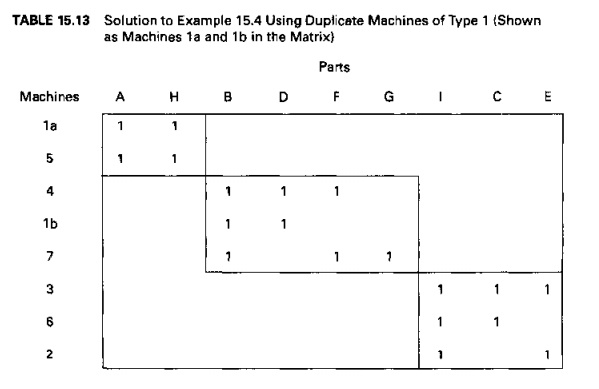

Suppose

that four machines. I, 2.3, and 4 have been identified as belonging in a GT

machine cell. An analysis of 50 parts processed on these machines has been

summarized in the From-To chart of Table 15.14. Additional information is that

'50 parts enter the machine grouping at machine 3,20 parts leave after

processing at machine 1, and 30 parts leave after machine 4. Determine a

logical machine arrangement using Hollier Method 1.

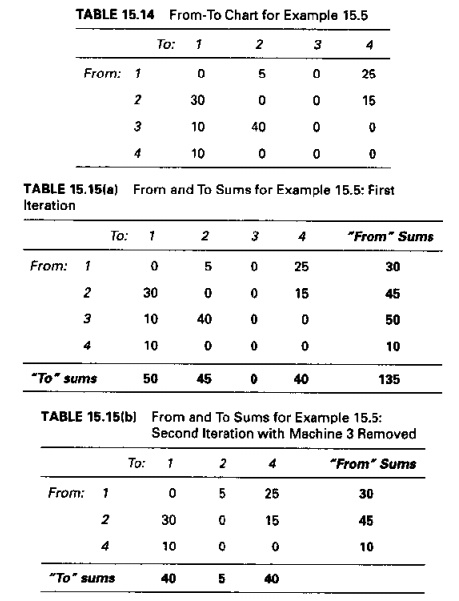

Solution: Summing the From trips and To

trips for each machine yields the "From" and "To" sums in

Table 15.15(a). The minimum sum value is the "To" sum for machine 3.

Machine 3 is therefore placed at the beginning of the sequence. Eliminating the

row and column corresponding to machine 3 yields the revised From-To chart in

Table 15.15(b). The minimum sum in this chart is the "To"

sum

corresponding to machine 2. which is placed at the front at the sequence,

immediately following machine 3. Eliminating machine 2 produces the revised From-To chart in Table 15.15(c).

The minimum sum in this chart is the "To" sum for machine I. Machine

I is placed after machine 2 and finally machine 4 is placed at the end of the

sequence. Thus, the resulting machine sequence is

3-- > 2 -- > 1 -- > 4

Hollier

Method 2. This approach is based on the use of From/To ratios formed by summing

the total flow from and to each machine in the cell. The method can he reduced

to three steps:

Develop the From-To

chart. This is the same step as in Hollier Method

1.

Determine

the From/To ratio for each machine. This i~ accomplished by summing up all of the "From" trips

and "To" trips for each machine (or operation). The "From"

sum for a machine is determined by adding the entries in the corresponding row,

and the "To" sum is determined by adding the entries in the

corresponding column. For each machine, the From/To ratio is calculated by

taking the "From" sum for each machine and dividing by the respective

"To" sum.

Arrange

machines in order of decreasing From/To ratio. Machines

with II high From/To ratio distribute work to many

machines in the cell but receive work from few machines. Conversely, machines

with a low From/To ratio receive more work than they distribute. Therefore,

machines are arranged in order of descending Prom/Io ratio. That is, machines

with high ratios are placed at the beginning of the work flow, and machine,

with low ratios are placed at the end of the work flow. in case of a tie, the

machine with the higher "From" value is placed ahead of the machine

with a lower value

EXAMPLE 15.6

Group Technology Machine Sequence using

Hollier Method 2

Solve

Example 15.5 using Hollier Method 2.

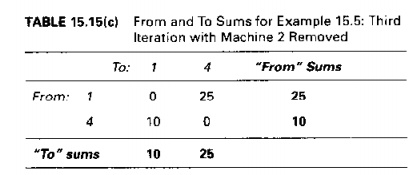

Solution: Table 15.15(a), containing the

"From" and "To" sums, is repeated in Table 15.16, along with the From/To ratios given in

the last column on the right. Arranging the machines III order of descending Prom/To

ratio, the machines in the cell should he sequenced as follows'

3 -- > 2 -- > 1 -- > 4

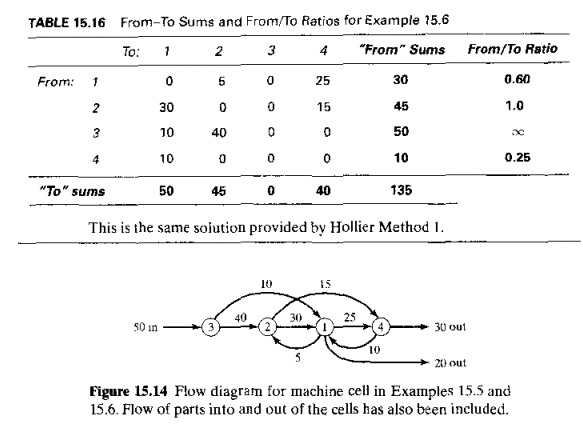

It is

helpful to use one of the available graphical techniques, such as the flow

diagram (Section 10.6.1), to conceptualize the work flow in the cell. The flow

diagram for the machine arrangement in Examples 15.5 and 15.6 is presented in

Figure 15,14. The work flow is mostly inline; however, there is some back flow

or parts that must be considered in the design of any material handling system

that might be used in the cell. A powered convey or would be appropriate for

the forward flow between machines. with

manual handling for the back flow.

For our

example data in Table 1'1.14, Hollier Methods 1 and 2 provide the same

solution. This is not always the case. The relative performance of the two

methods depends on the given problem. In some problems. Method J will

outperform Method 2.and in other problems the opposite will happen. In many

problems, the two methods yield identical solutions, as in Examples 15.5 and

15.0. Hollier presents a comparison of these and his other proposed methods

with a variety of problems in [17].

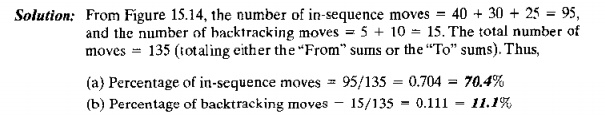

Two

performance measures can be defined to compare solutions to the machine sequencing problem: (1)

percentage of in-sequence moves and (2) percentage of backtracking moves. The percentage of in-sequence moves is

computed by adding

all of the values representing in-sequence moves and dividing by the total

number of moves. The percentage of

backtracking moves is determined by summing all of the values representing

backtracking moves and dividing by the total number of moves.

EXAMPLE 15.7 Performance Measures for

Alternative Machine Sequence ••in GT cell

Compute

(a) the percentage of in-sequence moves and (b) the percentage of backtracking

moves for the solution in Examples 15.5 and 15.6.

Related Topics