Types, Manufacturing Process, Finishing Process, Properties, Uses| Man-Made Fibres - Nylon Fibre | 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Chapter: 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Nylon Fibre

NYLON

Nylon is a generic name given to a group of

related compounds classified as Polyamides, just like cotton, linen and wool.

Nylon is a long chain of linear con-centrated polymer made from haxamethy-lene

diamine and adipic acid. Nylon is the first synthetic fibre made in 1928 during

a research at Dupont Company.

Nylon was invented by E.I.Du Pont de Nemours

& Co. The credit of the dis-covery of the nylon goes to Dr.Wallace H.

Carothers and his staff of organic chem-ists who worked in Du Pont’s chemi-cal

department. Realizing that there is a need of more active program of research

to provide new developments, Du Pont began a long range of programme in 1928.

Du Pont now shifted from applied research to fundamental research, which

primarily aimed to develop knowledge of chemicals, materials and processes.

After many months of research, Dr.Carothers

assistant discovered a poly-mer, which was a clear, heavy molasses when molten

and could be drawn out into filament. This was a polymer. It was called 6.6,

because there were six carbon atoms per molecule. Later it was called Nylon. It

is also known a polyamide.

Nylon is actually a group of related chemical

compounds. It is composed of hydrogen, nitrogen, oxygen and carbon in

controlled proportions and structural arrangements. Variations in the chemi-cal

structures can result in formation of compounds like plastic. The two types of

nylon are nylon 6.6 and nylon 6.

Types of Nylon Yarns

The diameter of the nylon yarn filament can be

determined by the rate of delivery from the pump to the spinneret and the rate

by which the yarn is drawn away from the spinneret. The size of yarn, which is

measured in denier, can be determined by the diameter and the number of

filaments in the yarn. Based upon this nylon can be divided as Nylon 6.6, Nylon

6.12, Nylon 4.6, Nylon 6, Nylon 12 and so on.

·

Monofilament Yarns.

·

Multifilament Yarns.

·

Stretch Yarns.

·

Textured Yarns.

·

Spun Yarns.

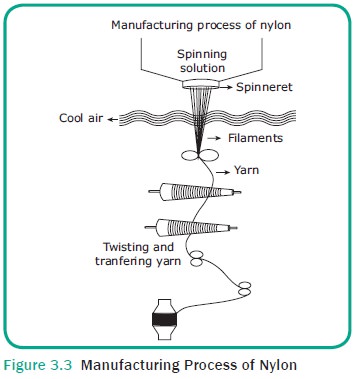

Manufacturing Process of Nylon

Required amount of hexamethylene diamine and

adipic acid are mixed to form nylon salt. This salt is dissolved in water at

the spinning mill and heated to get a con-centrated nylon salt solution. The

solution is placed in an autoclave under high pressure and heat which results

in giant chain links structure called “Linear Superpolymers”. The solution is

slowly passed over the auto-clave and a molten nylon resin is deposited on

wheel. This is sprayed with cold water to harden into opaque ribbon, flakes or

pellets. On melting this pellets or flakes are passed through the spinneret to

form nylon yarns (Figure 3.3).

Properties of Nylon

Shape :

Can be

modified as per requirement.

Size : Thin

long filament.

Density

: 1.1 g /

ccm

Lustre

: Varies

from brightness to dullness

Strength

: Good

Elongation

: Good

Elastic

recovery : 100%

Resiliency

: Good

Moisture

absorption : 8%

Dimensional

stability : Excellent

Resistance

to acid : Poor

Resistance

to alkalies : Good

Sunlight

: Affected

by sunlight

Insects

: Normally

damages the fibres

Resistance

to flame : Self extinguishing

Finishing Nylon Fabrics

Nylon fabrics can be given various finishes.

Antistatic

finish : For reduction of electrostatic build up

Embossing

: For

patterns or designs

Heat

setting : For permanent shape

Moireing

: For

shimmer effect

Molding

: For

shaping fabrics

Nylonizing

: For

increased absorbency

Water

repellence : For added protection against water

Dyeing : For imparting colour to the fabric

Uses of Nylon Fabric

·

Nylon is used in women’s stockings or hosiery. It

is also used as a mate-rial for producing socks, swimwear, shorts, track pants,

active wear, draperies and bedspreads.

·

Nylon is used for making fishing nets, ropes,

parachutes and tyre cords.

·

Nylon is used in cookware since it has a

relatively high continuous ser-vice temperature.

·

Nylon is used for making plastic machine parts as

it is low cost and long lasting. It is often commonly used in the electronics industry

for its non-conductivity and heat resistance.

Related Topics