Types, Manufacturing Process, Finishing Process, Properties, Uses| Man-Made Fibres - Acetate fibre | 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Chapter: 11th Textiles and Dress Designing : Chapter 3 : Man-Made Fibres

Acetate fibre

ACETATE

Acetate fibres are chemical compounds of

cellulose and not the pure cellulose as in rayon fibres. These chemical

com-pounds have their own unique properties and in fact the various types of

cellulose acetate fibres differ from each other in properties. In 1865, Pant

Schutzenberger discovered the reaction of cellulose ace-tate. Later in 1903,

the German chem-ists Arthur Eiechengeun and Theodore Becker invented the fast

soluble form of cellulose acetate.

In 1904, cellulose acetate was developed by

Camille Dreyfus and his younger brother Henri in England, during World War I.

It was used as a non flam-mable lacquer for the fabrics used for cov-ering the

wings and fuselage of aircrafts. In 1918, they perfected the technique of

spinning this substance into lustrous fil-aments of “artificial silk”.

Subsequently, British Celanese Ltd. started the produc-tion of this fibre. In

1924, the commercial production of acetate fabric started in the United States

by Celanese Corp. In 1954, The Celanese Corp. of America undertook the

production of a variation of this chem-ical called cellulose triacetate. This

prod-uct is marketed by the Celanese Fibres Marketing Co. under the trademark

Arnel.

Types of Acetate

The different types of acetate are

1.

Diacetate

2.

Triacetate.

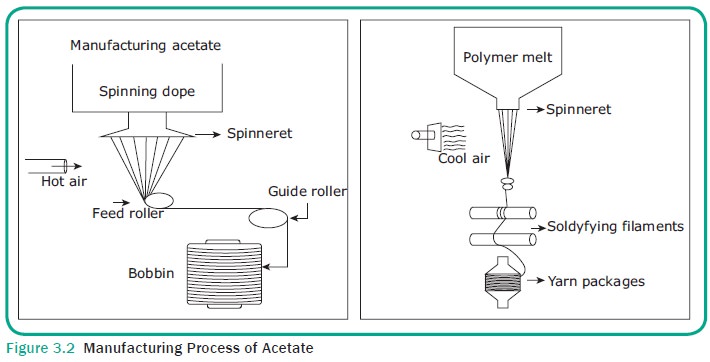

Manufacturing Process of Acetate

Pure cellulose is formed by converting cotton

linters or wood sheets. This pure cellulose is steeped in glacial acetic acid

and aged under controlled temperature for a period of time. It is then mixed

with acetic anhydride and a small amount of sulphuric acid as a catalyst to

facilitate the reaction which produces a thick and clear liquid solution of

cellulose acetate. This liquid is then passed through the spin-neret to form

these fibres which is solidi-fied and rolled on the bobbins for later use

(Figure 3.2).

Properties of Acetate and Triacetate

Shape :

Can be

modified as per requirement

Size : Thin

long filament

Luster : Variation from brightness to

dullness

Strength

: Good

Elongation

: Good up

to 25%

Elastic

recovery : Good

Resiliency

: Low for

acetate, but for triacetate it is good.

Dimensional

stability: Good

Resistance

to acids : Fair resistance to dilute acid, but cannot

withstand concentrated acid.

Resistance

to alkalis : Good resistance to dilute alkalis but cannot

withstand concentrated alkalis.

Resistance

to flame : Burns easily

Finishing Process

Depending upon the kind of yarns used and the

final effect desired, different fin-ishes can be given to acetate fabrics. The

most common finishes are :

Embossing

: For

pattern or design

Heat

setting : For

crease and shape retention

Moireing

: For

permanent watermarking effect

Napping

: On spun

acetate for softness and warmth

Sizing

: For

better appearance

Water

repellency : For resistance to water and rain

Wrinkle

resistance : For better shape retention

Uses of Acetate

The uses of acetate are :

·

The breathable nature of the fabric makes it

suitable for use as a lining fabric for apparels.

·

Acetate is used for making cigarette filters and

other filters, ink reser-voirs for fibre tip pens.

·

It is used for making high absor-bency products

like diapers and sur-gical products.

·

It is also used for making eyeglass frames.

Related Topics