Chapter: Mechanical : Mechatronics : Programmable Logic Controller

Mechatronics - Programmable Logic Controller

PROGRAMMING LOGIC CONTROLLERS

DEFINITION OF PLC:

A programmable logic

controller (PLC) Program

is a specially

designed digital operating microprocessor-based controller

that uses a programmable memory for internal storage of instructing and for internal

storage of instructing and for implementing function such as logic, sequencing,

timing, counting and arithmetic in order to control machines and processes.

BASIC COMPONENTS OF PLC:

The PLC

hardware system consists of the basic components are

Processor

Memory

Power

Supply

Input I

Output modules

Programming

device

Monitor

Processor:

It is the

heart of PLC

He processor processes the signals from input module and

generates controlling signals for the system

It also scans and solve the logic

of the user program

It

consists of ALU, microprocessor unit, memory unit and system power supply

Memory:

The

memory unit contains the program stored in it

The programs were written with control actions to be executed

by the microprocessor for the input given

RAM is a temporary storage device used to store ladder diagram

and for testing and evaluation Then it is stored in ROM where changes cannot

done

Power Supply:

The purpose of a power supply unit is to convert the main A.C

voltage into a low - level D.C voltage (5V).

The D.C. voltage is supplied to the processor and the circuits

in the input and output interface modules. The power supply should be free from

heavy loads, noises and voltage fluctuations.

Input / Output Modules:

The Input module receives information from extended devices

and sends to processor and communicates the processed information to the

external devices through output modules.

The Input devices are mechanical switches, photo sensors,

temperature sensors, flow sensors, other type of sensors keypads etc.,

The

output devices may include solenoid valves, Relays, contactors, lights, Horns,

Heating elements, fans, Motor starter, signal Amplifiers.

Conveyor belt, lift, automatic door etc., I/O devices are also called

peripheral devices.

Programming Device:

It is

used to enter the required program into the memory of the CPU

The

program is developed in programming device and stored into memory unit

BASIC STRUCTURE OR (INTERNAL ARCHITECTURE) OF A

PLC SYSTEM:

Central Processing Unit:

The CPU

controls and processes all the operations within the PLC.

It is

supplied with a clock with a frequency of typically between 1 to 8 MHz.

This frequency determines the operating speed of the PLC and

provides the timing and synchronization for all elements in the system.

The

information within the PLC is carried by means of digital signals.

The processor is a microprocessor that executes a program to

perform the operations specified in a ladder diagram or a set of Boolean

equations.

The CPU

consists of the following units

Arithmetic and Logic Unit (ALU):

This unit performs data manipulation and

arithmetic and logical operations on input I variable data and determines the

proper state of the output variables.

The arithmetic operation includes addition, subtraction etc.,

and logic operations include AND, OR, AND, EXCLUSIVE - OR.

Memory Unit:

Memory termed registers located within the microprocessor and

used to store information involved in a program execution.

These programs contain control actions to be executed by the

microprocessor for the given input. There are several memory elements in a PLC

system.

System Read-only Memory (ROM) gives permanent storage for the

operating system and fixed data wed by the CPU.

RAM for

the user to develop program and acts a temporary memory.

In

addition, temporary buffer stores for the I/O channels.

Control

Unit:

A control

unit is used to control the timing of operations.

The processor functions under a permanent supervisory

operating system that directs the overall operations from data input and output

to execution of user programs.

The controller can perform only one operation at a time. So,

it scans each of the inputs sequentially, evaluates the ladder diagram program,

provide each output(s), and then

repeat

the whole process.

Hence,

the timing control's necessary for a PLC system.

Memory Unit:

The

sequence of instructions to be executed, programs are stored in the memory

unit.

During entering and editing including Debugging, the program

is stored in the temporary storages called RAM (Random Access memory).

Once the

program is completely finished (free & from errors).

It may be

'burned' into ROM

When the ROM is plugged into the PLC, the device is ready to

be placed into service in the industrial environment.

For network programmed PLCs, the final PLCs program is

downloaded into a special re-programmable ROM (EPROM, PROM, and EEPROM) in the

PLC.

Memory

may be either volatile type or Non-volatile type.

Volatile Memory:

Volatile memory or temporary memory or Application memory is

the user memory, where the user can enter and edit the program.

Volatile memory will lose all its programmed contents if

operating power is removed or lost. Therefore, necessary to provide a battery

backup power to all times.

Non Volatile Memory:

Non-volatile memory or permanent memory or system memory is

(used) a system memory that stores the monitor a booting programs, lookup

tables etc.,

This

usually programmed and supplied by the manufacturer.

This

controls the operation of PLC.

It does

not lose its content during power failure.

It does

not require any battery.

The ROM

memory offers the CPU to use only fixed amount of data.

The Different Types of ROMS are

Mask

programmed ROM

PROM

EPROM

EEPROM

Mask Programmed ROM:

It is a

special type of ROM which is programmed during manufacturing.

The

programmed content stored by this type of ROM memory cannot be altered.

PROM:

PROM

stands for programmable Read only memory.

It is a

special type of ROM usually programed by manufacturer during manufacturing.

It has the disadvantage of requiring special programming

device and once programmed cannot be erased or altered.

EPROM:

EPROM

stands for electrically programmable Read only Memory.

Here, the

user programs electrically.

One can erase the program completely by shining UV

light source or quartz window in package. After the program chip is erased

completely, program changes can be made.

When the program developed in RAM, the manufacturers usually

load it in EPROM to make permanent storage.

EEPROM:

EEPROM -

Electrically Erasable programmable Read-only memory.

Even though, it is a non-volatile memory, it offers some

programming flexibility as RAM. One can erase the program completely by

electrical signals.

Program

changes can be made very easily with the use of a PC with EEPROM software.

It can be

electrically programmable by the user.

Buses:

A set of parallel lines that provides communication between

various devices of a system is termed as a Bus.

The bus system carries information and data’s to and from the

CPU, Memory and I/O units. The information is transmitted in binary form as 0

or 1

Digital signals

or electrical signals are flowing inside the bus.

It might

be tracks on a printed circuit board (PCB) or wires in a ribbon cable.

The PLC

system contains four buses.

They are

namely Data Bus, Address Bus, Control bus and system bus.

Data Bus:

The data bus contains 8, 16 or 32 parallel signal lines for

sending data between the various devices of a system.

An 8-bit

microprocessor has an internal data bus which can handle 8-bit numbers.

The

double ended arrows on the bus line show that they are bidirectional.

This means that CPU can read data in from memory or from I/O

unit on these lines or it can send data out to memory or to I/O unit on these

lines.

Many devices in a system will have their outputs connected to

the data bus, but only one device will have its output enabled at a time.

Address Bus:

The Address bus contains 16, 20, 24 or 32 parallel signal

lines to carry the Address of the memory locations for accessing stored data.

Every memory location is given a distinct unique address to locate

easily and accessed by the CPU either to read or write data.

Control Bus:

The Control bus contains 4 to 10 parallel signal lines to

carry the signals used by the CPU that are related to internal Control actions.

Typical control bus signals are Memory

read

Memory write, I/O Read and I/O write.

I/O System Bus:

The I/O

system bus provide the communication between the I/O ports and I/O units

Input / Output Unit:

The I/O units provide the interface between the system and the

outside world, allowing for connections to be made through I/O channels to

input / output devices.

Programs

are entered from a program panel through I/O unit.

INPUT / OUTPUT PROCESSING:

The

sourcing and sinking are used to describe the way in which DC devices are connected

to PLC

Sourcing:

If a switch is connected to the positive of the battery and

current flows from positive to negative, it is said to be the sourcing the

current. So, the input device receives current

from the

input module.

For the PLC, input unit, hence input module is the source of

the current. For the PLC output unit, output module is the source of current as

it supplies current to the output

devices.

Sourcing output units for interfacing with solenoids.

Sinking:

Here, the input device supplies current to the input module.

For the PLC input unit, hence the input module is the sink for the current.

Sinking input units are used for

interfacing

with electronic equipment.

So, if a switch is connected to the negative of the battery

and current flows from positive to negative, by conventional current flow

direction, it is said to be the sinking for

Current.

For the PLC output unit, the current flows from output device to the output

module then the

output

module is the sink for current.

STEPS INVOLVED IN INPUT / OUTPUT PROCESSING:

The

sequence followed by a PLC when carrying out a program can be as

follows:

Scan the

inputs associated with one rung of the ladder program

Solve the

logic operation involving those inputs.

Set /

Reset the outputs for that rung

Move on

the next rung and repeat the operations 1, 2, 3

The two

methods of Input/ Output processing operations are

Continuous

updating

Mass

Input / Output copying

Continuous Updating:

The

sequence followed thus in continuous updating is as follows:

Fetch and

decode the first program instruction

Scan

there relevant inputs

Fetch and

decode the second program instruction

Scan the

relevant inputs etc. For the remaining program instructions

Update

outputs

Report

the entire sequence.

Mass Input / Output Copying:

The

sequence followed in Mass I/O copying is thus:

Scan all

the inputs and copy into RAM

Fetch and

decode and execute all the program instructions in sequence

Copy all

the output instructions to RAM

Update

all outputs.

Repeat

the sequence

PLC LOGIC:

Instruction Code Mnemonics:

AND Logic Function:

AND logic

circuit represents series circuit

AND gate

is composed with two inputs and one output.

AND gate

produce output when both the inputs are HIGH state.

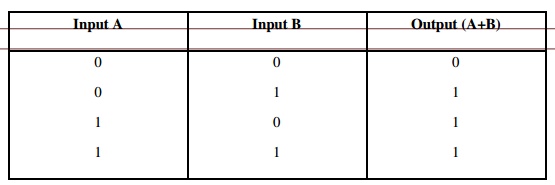

OR Logic Function:

OR logic

circuit represents the parallel circuit.

OR Gate

is composed of two or more inputs and one output.

OR

operation is like addition of binary numbers.

OR gate

produce output when any one input are HIGH state.

NOT Logic Function:

NOT

function is also known as Inverter.

NOT gate

is composed of single input and a single output.

The

bubble, or circle, at the output is the standard symbol used to represent

inversion.

In NOT

gate, there is an output, when there is no input and no output when there is an

input

NAND Logic Function:

NAND is a

combination of AND and NOT gates.

Arrangement shows AND gate is followed by NOT gate. Hence it

is called NOT AND gate. Both the inputs A and B have to be at LOW state to get

the output at HIGH state.

NAND Gate is composed of two or more input with a single

output. Any one input is in LOW state also output will be HIGH state

NOR Logic Function:

NOR is a

combination of OR and NOT gates.

Arrangement shows OR gate is followed by NOT gate. Hence it is

called NOT OR gate. Both the inputs A and B have to be at LOW state to get the

output at HIGH state.

NOR Gate is composed of two or more input with a single

output. Any one input is in HIGH state also output will be LOW state

Exclusive OR (XOR) Logic Function:

When both

the inputs are at LOW state the output will be at LOW state

When both

the inputs are at HIGH state the output will be at LOW state

When any

one input is HIGH state the output will be at HIGH state

latching:

It is necessary to hold an output coil energized, even when

the input ceases The term latch is used for the circuit used to carry out such

an operation.

Latch circuit is a self – maintaining circuit that maintains

its output in an energized state until the next input is updated

TIMER:

A timer is a special counter ladder function that allows the

PLC to perform timing operations based on a precise internal clock.

Types of Timers:

Delay ON

Timers or ON delay timers

Delay OFF

Timers or OFF delay timers

Pulse

Timers

Cascaded

Timers

ON-OFF

Cycle Timers

One Shot

Timers

Delay ON Timers:

The term

delay is used to indicate that this timer burns on, after waiting for a fixed

time delay period.

When there is an input, the timer is energised and starts

timing, after some pre-set value, the timer contacts are closed to output.

TON is

used to denote ON-delay.

Delay OFF Timers:

OFF delay timers are maintained as ON for a fixed time of

delay period before turning off. TOF is used to denote OFF-delay.

Pulse Timers:

Pulse timer switches is another type of Timer which comes

either ON or OFF for a fixed period of time as a function of pulses.

TP is

used to denote Pulse Timers

Cascaded Timers:

Cascading

means more elements are linked together to form a system.

The cascading timers are linked together to give longer delay

times which is easily achieved than just one timer.

ON – OFF Cycle Timer:

Timers producing an output for some period and no output for

some period and an output for some period.

The timer

is designed to switch an output for T sec and off for another T second

One Shot Timers:

One shot

timers produces an output for a fixed length of some initiation input.

INTERNAL RELAY:

An internal relay behaves like relays with their associated

contacts, buy they are not actual relays whose simulations are controlled by

the PLC software.

Internal

relays can be very useful in the implementation of switching sequences.

They are

often used when there are programs with multiple input conditions.

They are

also known as Auxiliary relays or markers.

In using an internal relays, it has to be activated on one

rung of a program and then its output used to operate switching contacts on

another rung of a program.

COUNTERS:

Counters

are used to count a specified number of contact operations.

Types of Counters:

Up

Counters

Down

Counters

Up Counters:

Up

counters count up from the zero to pre – set value

The

events are added until the pre – set value is reached

When the

counter reaches the set value, its contacts change state

Down Counters:

Down

counters count down from the pre – set value to zero

The

events are subtracted until the pre – set value is reached

When the

counter reaches the Zero value, its contacts change state

SHIFT

REGISTER:

A shift register is an electronic storage device that allows

the stored bits of one relay to get shifted into another relay.

DATA

HANDLING:

The steps

involved in data handling with a PLC system are

Moving

data from one memory location to another

Comparison

of Magnitudes of data

Arithmetic

operations

Data

conversion

Data – Handling Source Destination

Instruction Address Address

Data

Movement:

Instruction : MOV

Function : To copy a value from one address to

another

Program:

LD X400

MOV

D1

D2

When

there is an input to X400,

The data moves from the designated source address to the

designated destination address. The data transfer might move a constant into a

data register

Data

Comparison:

The data

comparison instruction gets the PLC to compare two data values.

It

compare a pre – set value (1) to the input value (2)

= or EQU

> or GRT

< or LEQ

≠ or

<> or NEQ

> or GEQ

For data comparison the typical instruction will contain the

data transfer instruction to compare the data from source address and

designation address

It is required to sound an alarm if a sensor indicates a

temperature above 90˚C and remain sounding until the temperature falls below

75˚C.

For this,

the ladder diagram is shown above.

The input temperature data is inputted to the source address

and the destination address contains the set value.

When the temperature rises 90˚C or higher, the data value in

the source address becomes >the destination address value and there

is an output to the alarm which latches the input

When the temperature falls to 75˚C or lower, the data value in

the source address becomes < the destination address value and there is an

output to the relay which then

opens the

contacts and so switches the alarm off.

Data Arithmetic Operations:

PLCs are offered with the ability to carry out the arithmetic

operations such as addition, subtraction, multiplication and division only.

They

cannot carry out exponential functions.

Addition and subtraction operations are used to alter the

value of data held in data registers. Multiplications are used to multiply some

input before adding to or subtracting it from another.

Code Conversions:

All the internal operations in the CPU of a PLC are carried

out through binary numbers. Most PLCs provide BCD-to-binary and binary-to-BCD

conversion for use.

When a decimal (input) signal is given, BCD conversion is

used. Similarly, when a decimal output is required, Decimal conversion is used.

The data

at the source address is in BCD and converted to binary and placed at the

destination address.

SELECTION OF PLCS

The

selection process of PLC for a particular task depends on the following

factors.

Capacity

of Input and Output

No. of

Inputs and Outputs

Types of

Inputs and Outputs

Size of

memory required I,

Speed and

Power required of the CPU

Related Topics