Chapter: Civil : Design of Reinforced Concrete Elements : Limit State Design Of Columns

Limit State Of Collapse: Compression

LIMIT STATE OF COLLAPSE: COMPRESSION

Assumptions

1. The

maximum compressive strain in concrete in axial compression is taken as 0.002.

2. The

maximum compressive strain at the highly compressed extreme fibre in concrete

subjected to axial compression and bending and when there is no tension on the

section shall be 0.0035 minus 0.75 times the strain at the least compressed

extreme fibre.

In

addition the following assumptions of flexure are also required

3. Plane

sections normal to the axis remain plane after bending.

4. The

maximum strain in concrete at the outermost compression fibre is taken as

0.0035 in bending.

5. The

relationship between the compressive stress distribution in concrete and the

strain in concrete may be assumed to be rectangle, trapezoid, parabola or any

other shape which results in prediction of strength in substantial agreement

with the results of test.

6. An

acceptable stress strain curve is given in IS:456-200. For design purposes, the

compressive strength of concrete in the structure shall be assumed to be 0.67

times the characteristic strength. The partial safety factor y of 1.5 shall be

applied in addition to this.

7. The

tensile strength of the concrete is ignored.

8. The

stresses in the reinforcement are derived from representative stress-strain

curve for the type of steel used. Typical curves are given in IS:456-2000. For

design purposes the partial safety factor equal to 1.15 shall be applied.

Minimum eccentricity

As per IS:456-2000, all columns

shall be designed for minimum eccentricity, equal to the unsupported length of

column/ 500 plus lateral dimensions/30, subject to a minimum of 20 mm. Where

bi-axial bending is considered, it is sufficient to ensure that eccentricity

exceeds the minimum about one axis at a time.

Short Axially Loaded Members in Compression

The

member shall be designed by considering the assumptions given in 39.1 and the

minimum eccentricity. When the minimum eccentricity as per 25.4 does not exceed

0.05 times the lateral dimension, the members may be designed by the following

equation:

Pu

= 0.4 fck Ac + 0.67 fy Asc

Pu

= axial load on the member,

fck = characteristic compressive strength of the

concrete, Ac = area of concrete,

fy = characteristic strength of the compression reinforcement,

and As = area of longitudinal reinforcement for columns.

Compression

Members with Helical Reinforcement

The strength of compression members with helical reinforcement

satisfying the requirement of IS: 456 shall be taken as 1.05 times the strength

of similar member with lateral ties.

The ratio of the volume of helical reinforcement to the volume

of the core shall not be less than

Vhs

/ Vc > 0.36 (Ag/Ac - 1) fck/fy

Ag

= gross area of the section,

Ac = area of the core of the helically reinforced

column measured to the outside diameter of the helix,

fck

= characteristic compressive strength of the concrete, and

fy

= characteristic strength of the helical

reinforcement but not exceeding 415 N/mm.

Members

Subjected to Combined Axial Load and Uni-axial Bending

Use of

Non-dimensional Interaction Diagrams as Design Aids

Design

Charts (for Uniaxial Eccentric Compression) in SP-16

The design Charts (non-dimensional interaction curves) given

in the Design Handbook, SP : 16 cover the following three cases of

symmetrically arranged reinforcement :

(a)Rectangular

sections with reinforcement distributed equally on two sides (Charts 27 - 38):

the 'two sides' refer to the sides parallel to the axis of bending; there are

no inner rows of bars, and each outer row has an area of 0.5As this

includes the simple 4-bar configuration.

(b) Rectangular

sections with reinforcement distributed equally on four sides (Charts 39 - 50):

two outer rows (with area 0.3As each) and four inner rows (with area

0.1As each) have been considered in the calculations ; however, the

use of these Charts can be extended, without significant error, to cases of not

less than two inner rows (with a

minimum

area 0.3A in each outer row).

s

(c) Circular

column sections (Charts 51 - 62): the Charts are applicable for circular

sections with at least six bars (of equal diameter) uniformly spaced

circumferentially.

Corresponding

to each of the above three cases, there are as many as 12 Charts available

covering the 3 grades of steel (Fe 250, Fe 415, Fe 500), with 4 values of d1/

D ratio for each grade (namely 0.05, .0.10, 0.15, 0.20). For intermediate

values of d1/ D, linear interpolation may be done. Each of the 12

Charts of SP-16 covers a family of non-dimensional design interaction curves

with p/fck values ranging from 0.0 to 0.26.

From this, percentage of steel

(p) can be found. Find the area of steel and provide the required number of

bars with proper arrangement of steel as shown in the chart.

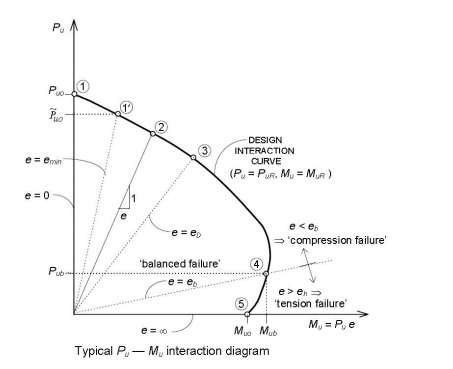

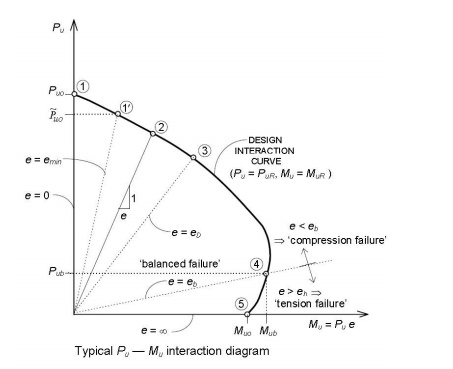

Typical

interaction curve

Salient Points on the Interaction Curve

The salient points, marked 1 to 5

on the interaction curve correspond to the failure strain profiles, marked 1 to

5 in the above figure.

• The point

1 in figure corresponds to the condition of axial loading with e = 0. For this

case of 'pure' axial compression.

• The point

11 in figure corresponds to the condition of axial loading with the

mandatory minimum eccentricity emin prescribed by the Code.

• The point

3 in figure corresponds to the condition xu = D, i.e., e = eD.

For e < eD, the

entire section is under compression and the neutral axis is

located outside the section (xu > D), with 0.002 < ?cu < 0.0035. For e > eD,

the NA is located within the section (xu < D) and ?cu = 0.0035 at the 'highly

compressed edge'.

• The point

4 in figure corresponds to the balanced failure condition, with e = eb

and xu = xu, b . The design strength values for this

'balanced failure' condition are denoted as

Pub

and Mub.

The point

5 in figure corresponds to a 'pure' bending condition (e = ?, PuR = 0); the resulting ultimate moment of

resistance is denoted Muo and the corresponding NA depth takes on a

minimum value xu, min.

Related Topics