Chapter: Chemistry : Fuels and Combustion

Important Questions and Answers: Fuels and Combustion

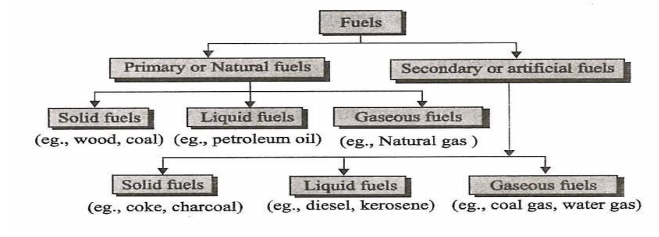

1. How fuels are classified. Give

one example for each.

Based on

Occurrence - 2 Types.

Primary Fuels – It occurs in nature such as. Ex:

Coal, Crude oil, Natural Gas.

Secondary

Fuels – It is derived from primary fuels. Ex: Coke, Petrol, Coal gas. Based on

physical state – 3 types

Solid fuels, eg., coal, coke,

Liquid fuels eg., gasoline, diesel.

Gaseous

fuels eg., coal gas, natural gas.

2. Define calorific value.

Explain higher & lower calorific value.

It is defined as the amount of heat obtainable by

the complete combustion of a unit mass of the fuel. Units of Calorific value ; Calorie,

kilocalorie, British thermal unit, centigrade heat unit Higher calorific value

/ Gross calorific value (GCV)

GCV = The

total amount of heat is produced, when a unit quantity of the fuel is

completely burnt and the products of combustion are cooled to room temperature

is known as GCV.

Lower

calorific value / Net calorific value (GCV)

NCV = The

total amount of heat is produced, when a unit quantity of the fuel is

completely burnt and products of combustion are allowed to escape is known as

NCV

NCV = GCV

-0.09H x 587.

3. Explain proximate analysis.

Give its significance.

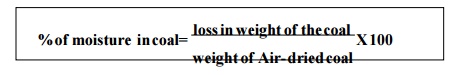

It involves the determination of % of moisture

content, volatile matter, ash content & fixed carbon in coal.

(i) Moisture content: About 1

gram of air-dried powdered coal sample is taken in a crucible & it is

heated at 100-105°C for 1 hour.

(ii) Volatile matter: After

the analysis of moisture content, the crucible with residual coal sample is

converted with lid & it is heated upto 950°C for 7 minutes.

(iv) Fixed carbon: It is

determined by the subtracting the sum total of moisture, volatile & ash

content from 100.

% of fixed carbon in coal = 100 - % of (moisture

content + volatile matter + ash content)

Significance or importance of

Proximate Analysis:

High % of moisture is undesirable because it

reduces the calorific value of a fuel, & increases the transport cost.

High % of matter is undesirable because it reduces

the calorific value of a fuel & coal burns with a long flame & high

smoke.

High % of ash content is undesirable because it

reduces the calorific value of a fuel & makes the additional cost of

disposal of ash.

High % of fixed carbon in a coal, is greater its

calorific value.

4. Explain ultimate analysis.

Give its significance.

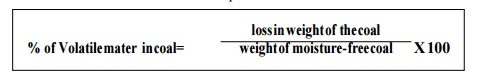

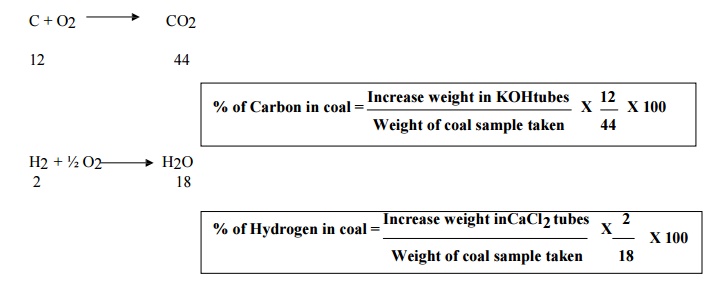

It involves

the determination of % of Carbon, Hydrogen, Nitrogen, Sulphur & Oxygen in

coal.

1. Carbon & Hydrogen: A known

aount of coal sample is burnt with o2 in a combustion apparatus. In coal carbon & hydrogen are converted

into CO2 & H2O & those are absorbed by KOH tubes & CaCl2 tubes.

2. Nitrogen:

It is

carried out by Kjeldahl‟s method. A known amount of coal is heated with Con.

H2SO4 in presence of K2 SO4 catalyst in a long necked flask called Kjeldahl‟s

flask. Nitrogen is converted into ammonium sulphate. Then it is heated with

NaOH & absorbed by HCl.

3. Sulphur: A known

amount of coal is completely burnt in a bomb calorimeter. Here sulphur is converted into sulphate

& treated with BaCl2, BaSO4 is obtained.

Oxygen: The % of

oxygen is calculated as follows,

of Oxygen

in Coal = 100 - % of ( C + H+N+S+ash)

Importance or significance of

Ultimate analysis:

Higher % of carbon & hydrogen, better is the

quality of coal & higher its calorific value.

Should have very little nitrogen content.

Presence of sulphur is undesirable because it forms

harmful gases during the combustion.

Lower of the Oxygen increases the higher its

calorific value.

How

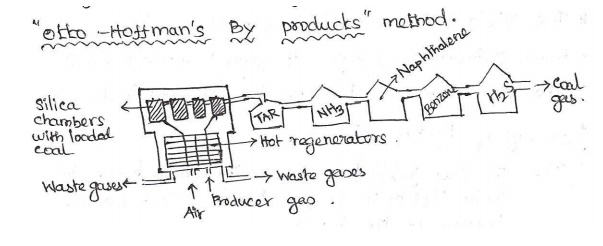

Metallurgical coke is manufactured by Otto-Hoffman’s method?

When bituminous coal is heated strongly in the

absence of air, the volatile matter escapes out & the mass becomes hard,

strong, porous, which is called metallurgical

coke.

Manufacture of Metallurgical coke

by “Otto- Hoffman’s by products” method:

In order to (i) Increase the thermal efficiency of

the carbonization process & (ii) Recover the valuable by products by this

method.

This oven

consists of a number of silica chambers.

Each

chamber is about 10-12 m long, 3-4 m height & 0.4 – 0.45m wide.

Coal is

introduced into the silica chambers & heated 1200°C by air & producer

gas. I & IV regenerators are heated by hot flue gases & II & III

regenerators are

heated by

incoming air & producergas.

When the

process is complete, the coke is removed & cool by with water. Time taken

for this process is 12-20 hours.

The yield

of the coke is about 70%

From out

coming flue gas, it gives valuable products like Tar, ammonia, benzene. H2S are

obtained.

Recovery of by products:

(i)

Tar: the flue gases are first passed through a

tower, in which liq. NH3 is sprayed, tar is collected at the bottom of the

tank.

(ii)

Ammonia: The gases are then passed through 2nd

tower, in which water is sprayed & NH3 gets in the form of NH4OH.

(iii)

Naphthalene: The gases are again passed through

next tower, cooled water is sprayed, Naphthalene gets & condensed.

(iv) Benzene: The gases are passed through next

tower, petroleum oil is sprayed, benzene gets condensed.

(v) H2S gas: The remaining gases are then passed

through a purifier, H2S gas is obtained. The final gas left out is called coal

gas.

Advantages:

(i)

Valuable by product like NH3, benzene, etc are obtained.

The carbonization time is less.(iii) Heating is

done by extremely by producer gas.

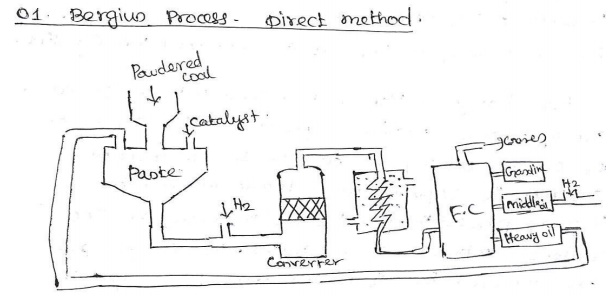

What do you mean by hydrogenation of coal? How

Synthetic petrol is manufactured by Bergius Process? Or How solid fuel is converted

into liquid fuel? Explain in detail.

The

preparation of liquid fuels from solid coal is known as hydrogenation of coal

& this gasoline is known as synthetic petrol.

Bergius

Process – Direct method:

Input :

Powdered coal + Ni Oleate catalyst + Heavy oil are made into paste + H

Heating

in : 400 - 450°C.

Pressure

: 200-250atm.

Process: Powdered coal is converted into gasoline.

In this

process powdered coal is mixed with Ni oleate & heavy oil & made into

paste.

It is

pumped along with H2 gas into the converter, the paste is heated to 400 - 450°C

under pressure of 200-250atm.

Crude oil

comes & it is fractionated into 3 parts.

1.

Gasoline. 2. Middle oil. 3. Heavy oil.

The

middle oil is further hydrogenated in vapour phase to get gasoline. The heavy

oil is recycled for making paste again coal powder.

60% of

yield is obtained from this process.

7.

Explain the following (i) Compressed natural

gas (CNG) (ii) Liquid

petroleum gas. (LPG)

Compressed

Natural Gas: (CNG)

Natural

gas (CH4) compressed to a pressure of about 1000 atm is known as CNG. Its

calorific value is 12000-14000kcal/m3.

It is

fully of methane only & derived from natural gas. Its composition is as

follows.

CH4 = 70-90% C2 H2 = 5- 10 % H2 = 3%

Uses: CNG is

a cheapest, clearest & the least polluting fuel for automobiles instead of

petrol or diesel.

(ii) Liquid Petroleum Gas: (LPG)

It is

obtained as a by- product during the cracking of heavy oil. Its composition is

Butane =

27% Isobut ene = 25% Butyle nes = 43% Propan e = 5%

Its

calorific value is 27,800 kcal /m3.

LPG is

marketed under the trade names like Indane, HP, Bharat gas in steel cylinders

under high pressure.

A small

amount of Ethyl mercaptan is added during filling of cylinders to help in

detecting leakage of gas.

LPG

ensures complete combustion with no smoke & causes the least environmental

pollution.

Uses:

It is used as a domestic fuel.

It is used as a fuel in vehicles (i.e) motor fuel.

It is used in industries & laboratories

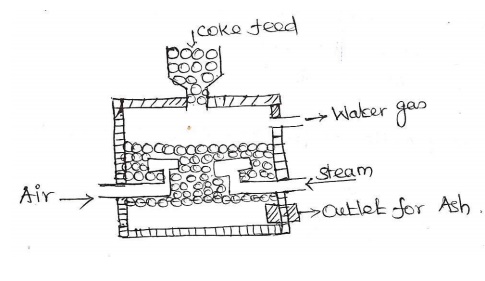

Explain

Water gas with reaction.

It is a

mixture of CO & H2 with small amount of N2.

Its

calorific value is about 2800kcal/m3.

Composition:

CO = 41%, H2 = 51%, N2 = 4% & CO2 = 4%.

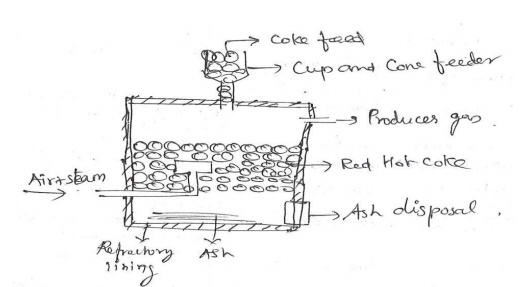

The water

gas producer consists of a tall steel vessel, lined with refractory bricks.

It is

provided with cup & cone feeder at the top & side opening for water gas

exists. At the bottom it is provided with 2 inlet pipes for passing air &

steam.

When

steam & little air is passed alternatively over a red hot coke maintained

at about 900-1000°C in a reactor, water gas is produced.

Two steps of reaction in production of water gas:

Here the

steam is passed through red hot coke, where CO & H2 gases are produced. The

reaction is endothermic.

Step 2: C + O2 --- > CO2. EXOTHERMIC.

Uses:

It is used for preparation of power alcohol.

For the production of H2 & in synthesis of NH3.

To manufacture synthesis petrol in Fischer – Tropsh

process.

Explain

Producer gas with reaction.

It is a

mixture of CO & N2 with small amount of

H2. Its

calorific value is about 1300 kcal/m3.

Composition:

CO = 30%, H2 = 10-15%, N2 = 51-56% & others = rest.

The

producer gas producer consists of a tall steel vessel, lined inside with

refractory bricks. It is provided with cup & cone feeder at the top &

side opening for producer gas exit.

At the

bottom it is provided with an one inlet for passing air & steam.

When a

mixture of air & steam is passed over a red hot coke at 1100°C in a

reactor, the producer gas is produced.

Uses:

It is a

used as a reducing agent in metallurgical operations.

Used for

heating muffle furnaces & open- hearth furnaces.

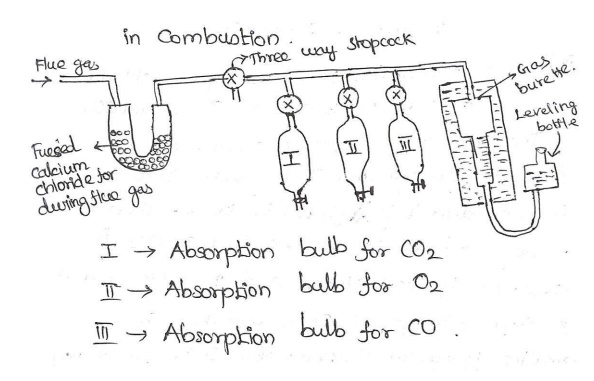

Describe

flue gas analysis by Orsat’s apparatus method.

Flue gas

analysis is carried out by Orsat apparatus method.

A mixture

of gases like CO2, CO, O2 & N2 etc coming out from the combustion chamber

is called flue gases.

If the

flue gas contains,

CO

-- It indicates incomplete combustion

&

O2 -- It

indicates excess supply of air used in combustion.

Apparatus: It consists a horizontal tube. At

one end this tube, U tube containing fused

CaCl2 is connected through 3 way stop cock. The other end is connected with

a graduated burette. The horizontal tube is also connected with 3 different

absorption bulbs I, II, III for absorbing CO2, CO and O2.

I bulb:

It contains KOH solutions & it absorbs CO2 only.

II bulb:

It contains Alkaline pyrogallol solution & it absorbs CO2, & O

III bulb:

It contains Ammoniacal cuprous chloride solution & it absorbs CO2,CO &

O

The 3 way

stop cock is connected with flue gas supply & it is sucked into the burette

& it is adjusted by 100cc. then the 3 way stop cock is closed. In bulb I,

co2 is absorbed by KOH solution & I is closed & II stopcock is opened,

O2 is absorbed by alkaline pyrogallol solution. Now II is closed & III is

opened. CO is absorbed by ammonical cuprous chloride. The decrease in volume of

the flue gas in the burette indicates the volume of I CO2, II O2,

III CO respectively.

Significance: It gives an clear idea about the

complete or incomplete process.

Related Topics