Chapter: Modern Analytical Chemistry: Kinetic Methods of Analysis

Flow Injection Analysis: Theory and Practice

Theory and Practice

Flow injection analysis (FIA) was

developed in the

mid-1970s as a highly efficient technique for

the automated analyses of samples.

Unlike the centrifugal analyzer described earlier, in which samples

are simultaneously analyzed

in batches of limited

size, FIA allows for the rapid, sequential analysis of an unlimited

number of samples. FIA is one member

of a class of techniques called continuous-

flow analyzers, in which samples are introduced sequentially at regular

intervals into a liquid

carrier stream that

transports the samples

to the detector.

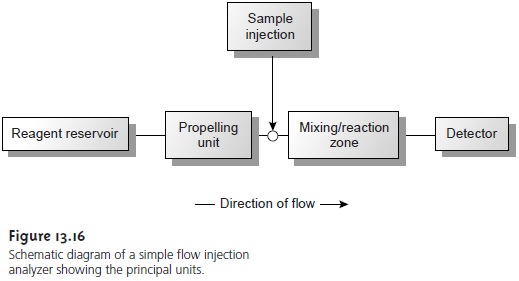

Figure 13.16 is a schematic diagram detailing the basic components of a flow injection analyzer. The reagent serving as the carrier is stored in a reservoir, and a propelling unit maintains a constant flow of the carrier through the system of tub- ing comprising the instrument. The sample is injected directly into the flowing car- rier stream, where it travels through a mixing and reaction zone before passing through the detector’s flow-cell. Figure 13.16 is the simplest design for a flow injec- tion analyzer, consisting of a single channel with one reagent reservoir. Multiple- channel instruments, in which reagents contained in separate reservoirs are combined by merging channels, also are possible. A more detailed discussion of FIA instru- mentation is found in the next section.

When a sample

is injected into

the carrier stream

it has the

rectangular flow profile (of

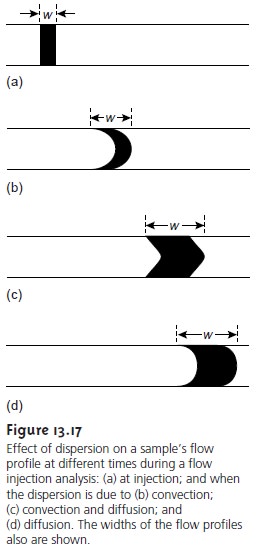

width w) shown in Figure 13.17a.

As the sample

is carried through

the mixing and reaction

zone, the width of the flow profile

increases as the sample dis- perses into the carrier stream.

Dispersion results from two processes: convection

due to the flow of the carrier

stream and diffusion due to a concentration gradient between the sample and

the carrier stream.

Convection of the

sample occurs by laminar flow, in which

the linear velocity of the sample

at the tube’s

walls is zero, while the sample at the center

of the tube moves with a linear

velocity twice that of

the carrier stream. The result

is the parabolic flow profile

shown in Figure

13.7b. Convection is the primary means

of dispersion in the first

100 ms following the

sample’s injection.

The second contribution to the sample’s

dispersion is diffusion due to the con-

centration gradient between the sample and the carrier stream. Diffusion occurs

parallel (axial) and perpendicular (radial)

to the flow of the carrier stream,

with only the latter

contribution being important. Radial diffusion decreases the linear velocity of the sample

at the center of the tubing, but the sample

at the edge of the tubing experiences an increase

in its linear velocity. Diffusion helps to maintain

the integrity of the sample’s flow profile (Figure

13.17c), preventing samples

in the car- rier stream from dispersing into one another.

Both convection and diffusion make significant contributions to dispersion from approximately 3–20 s after

the sample’s injection. This

is the normal

time scale for

a flow injection analysis. After approxi- mately 25 s, diffusion becomes the only

significant contributor to dispersion, result- ing in a flow

profile similar to that shown

in Figure 13.17d.

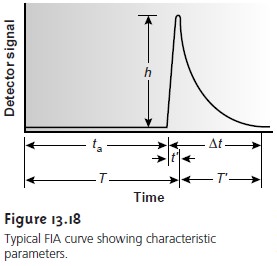

An FIA curve,

or “fiagram,” is a plot of the detector’s signal as a function of time. Figure 13.18 shows a typical

fiagram for conditions in which both convection

and diffusion contribute to the sample’s dispersion. Also shown

on the figure

are several parameters used to characterize the fiagram. Two parameters are used to de-

fine the time required for the sample

to move from the injector

to the detector. The travel time,

ta, is the elapsed

time from the sample’s injection to the arrival

of the leading edge of its flow profile

at the detector. Residence time, T, on the other hand, is

the time required

to obtain the maximum signal.

The difference between

the resi- dence time and travel time is given as t’. The value for t’ approaches 0 when convec- tion is the primary

means of dispersion and increases in value as the contribution from diffusion becomes more important.

The time required

for the sample

to pass through

the detector’s flow cell,

and for the signal to return to the baseline, is also described by two parame- ters. The baseline-to-baseline time,

∆t, is the elapsed

time between the arrival

of the leading edge of the sample’s flow profile to the departure of its trailing edge. The elapsed time

between the maximum

signal and its

return to the baseline is called the return time,

T

‘. The final

characteristic parameter of a fi- agram is the peak height, h, which

is equivalent to the difference between the maximum signal and the signal at the baseline.

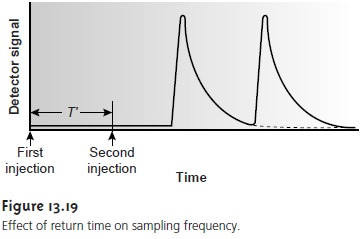

Of the six parameters shown in Figure 13.18, the most important are peak height and return time. The peak height is related, directly or indirectly, to the analyte’s concentration and is used for quantitative work. The sensitiv- ity of the method, therefore, is also determined by the peak height. The return time determines the frequency with which samples may be injected. Figure 13.19 shows that when a second sample is injected at a time T ‘ after injecting the first sample, the overlap of the two FIA curves is minimal. By injecting samples at intervals of T ‘, the maximum sampling rate is realized.

Peak heights and return times are influenced by the dispersion of the sample’s flow profile and are

influenced by the

physical and chemical properties of the

flow injection system. Physical

parameters affecting the peak height

and return time in-

clude the volume of sample injected; the flow rate; the length,

diameter, and geom- etry of the mixing

and reaction zone;

and the presence

of mixing points

where sep- arate channels

merge together. The kinetics of any chemical

reactions involving the sample and reagents in the carrier

stream also influences the peak height and re- turn

time.

Unfortunately, there is no good theory that can be used to consistently predict the peak height and

return time for

a given set

of physical and

chemical parameters. The design

of a flow injection analyzer

for a particular analytical problem

still oc- curs largely

by a process of experimentation. Nevertheless, some general

observa- tions about the effects of physical and chemical parameters can be made.

In the ab- sence of chemical

effects, sensitivity (larger

peak height) is improved by injecting

larger samples, increasing the flow rate, decreasing the length and diameter of the

tubing in the mixing and reaction zone,

and merging separate

channels before the point where the sample

is injected. Except

for sample volume,

an improvement in the

sampling rate (smaller

return time) is achieved by the same combination of physical parameters. Larger sample

volumes, however, lead to longer

return times and a decrease in sample throughput. The effect of chemical reactivity depends on whether the species monitored

by the detector is a reactant or a product.

For exam- ple, when the monitored species is a reactant, sensitivity is improved by selecting a combination of physical parameters that enables the sample to reach the detector

more quickly. Adjusting the chemical

composition of the carrier stream

in a man- ner that decreases the rate of the reaction also improves sensitivity in this case.

Related Topics