Chapter: Civil : Repair and Rehabilitation of Structures : Techniques for Repair and Demolition

Engineered demolition techniques for dilapidated structures

Engineered demolition techniques

for dilapidated structures

1 Modern Demolition Techniques

·

Hydralic Rock Breakers

·

Diamond sawing and Drilling

·

Silent expansive chemicals

·

Controlled Demolition

·

Hydralic Brusting / Spliting

·

Thermal lancing

·

Hydro demolition

·

Robolic demolition

·

Cor Drilling - uses

diamond tipped bits with hydraulic/electric/pneumatic geode drill motors - maximum

dia - 2000mm.

ü Wire Sawing : Ultimate Demolition Tool

In wire sawing a diamond beaded

wire is reared around the RCC members, to be cut. The wire is rotated at a high

speed (100Km/hr) by a special machine while constantly applying a pulling

force. The diamond wire penetrates and cuts through the steel and concrete.

Water is used as a lubricating

coolant. Wire sawing has limitations on the size of RCC member, to be cut. This

technique is ideal for fast primary demolition.

ü Hand Sawing

Han sawing uses a light weight

hand held machine, with diamond blade to cut RCC in any direction. By this

technique, even over hand cutting is possible. Max. Depth of cut is 150mm.

Diamond Advantage

ü Time : Diamond

tools cut concrete fast, reducing down time which Leeds to early project

completion.

ü Limensional

Tolerance: Diamond cutting is precise and controlled, little or no patching

s required.

ü Structural

Integrity : Diamond cutting allows removal of large amounts of

concrete without damaging, remaining or surrounding structures.

ü Noise ,

Dust and Debris: Diamond cutting is relatively quiet and virtually

dust free concrete pieces can be cut to specified size for easy removal.

ü Limited

Access: Diamond cutting techniques can e used in confined areas and

arrows existing equipment

Hydraulic Splitters/Busters:

Creates enormous sresses within

concrete, producing tensile cracking of concrete.

Dismantling

Tools

Hand

Operated Machines

Crane

Mounted machines

ü Special

Machine

ü Robotic

machine

Tools to

be used for job on Haul

The

following factors should determine the technique

ü Volume

of concrete to be dismantled

ü Space

available for walling

ü Risks

involved

ü Acceptable

noise and Vibration levels

Hand Held Machines

ü Electrically

Operated

ü Battery

operated

ü Pneumatic

ü Hydraulic

ü Engine

Key

Factors

General

ü Weight

ü Multifunction

- Drill,

Chip, Hammer Drill

ü Ergonomics

Technical

ü Energy

Per Stroke

ü Material

Removal Per minute

ü Tool

Mount Type

ü Tool Life

ü Maintenance

Cost

ü Safety

Features

ü Durability

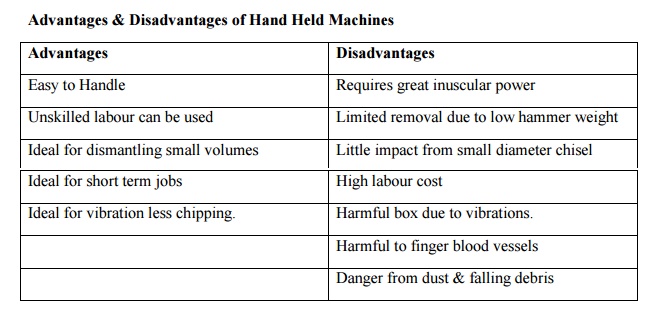

Advantages & Disadvantages of

Hand Held Machines

Advantages

Easy to Handle

Unskilled labour can be used

Ideal for dismantling small volumes

Ideal for short term jobs

Ideal for vibration less

chipping.

Disadvantages

Requires great inuscular power

Limited removal due to low hammer

weight

Little impact from small diameter

chisel

High labour cost

Harmful box due to vibrations.

Harmful to finger blood vessels

Danger from dust & falling

debris

Related Topics