Textiles and Dress Designing - Dyeing Methods | 12th Textiles and Dress Designing : Chapter 2 : Dyeing

Chapter: 12th Textiles and Dress Designing : Chapter 2 : Dyeing

Dyeing Methods

Dyeing Methods

The art of

dyeing dates back to

pre-historic times. It is practised from ancient time and it is as old

as human

civilization.

Dyeing is the process of imparting colour to the fibre/yarn or

fabric by the application of dyes or pigments. Colour is produced between the dye

molecule and the fibre or fabric. The bond between dye molecule and fibre may

be strong or weak depending on the dye used. Dyeing enhances the aesthetic look

of the fabric. It is one of the surface ornamentation methods.

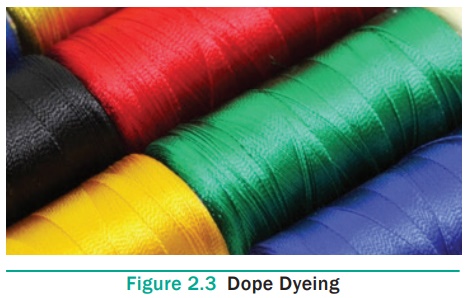

1. Stages of Dyeing

Dyeing can be done at any stage of textile production process such

as at fibre stage, yarn stage, fabric or finished product.

1. Dyeing at Fibre Stage

The process of dyeing at fibre stage is called as fibre dyeing. It

includes stock dyeing, top dyeing and dope dyeing.

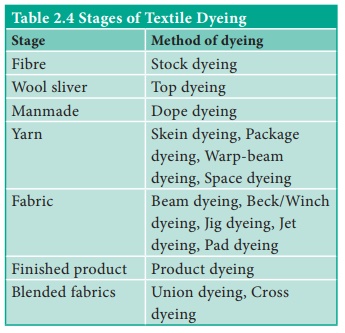

Stock Dyeing

Fibres are dyed by the process of stock dyeing. In this method,

dyeing is carried out in a large enclosed vessel called kiers. Fibres are

placed loosely in perforated containers and kept inside the kiers. The dye

liquor is circulated through the fibres at high temperature until the desired

colour is obtained. Excess dye solution is removed after dyeing process. The

dyed fibres are washed and dried.

Advantages

·

Produces varied colour effects by blending different coloured

fibres

·

Large quantities of fibres can be dyed at one time

·

Produces uniform colour

·

Colour fastness ranges from good to excellent

·

Dye easily penetrates the fibres and hence crocking is prevented.

Disadvantages

·

Expensive and time consuming

·

Fibre wastage if not consumed immediately

·

Dyed fibres loses its flexibility and hence not readily spin as

undyed fibre

·

Cannot withstand rapid changes in fashion

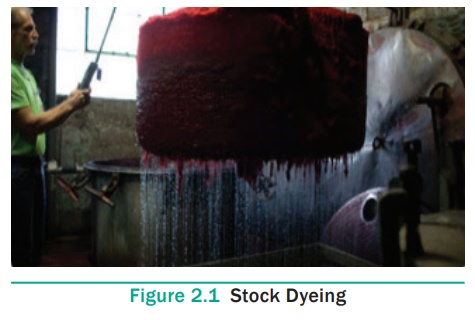

Top Dyeing

Wool that has been combed to remove short fibres is called as top.

Top is wound on perforated spools and dye solution is passed through it. Top

dyeing method results in even dyeing.

Advantages

·

Uniform dye uptake

·

Dye penetrates into the fibre therefore good colour fastness

Disadvantages

·

Flexibility is reduced

·

Time consuming

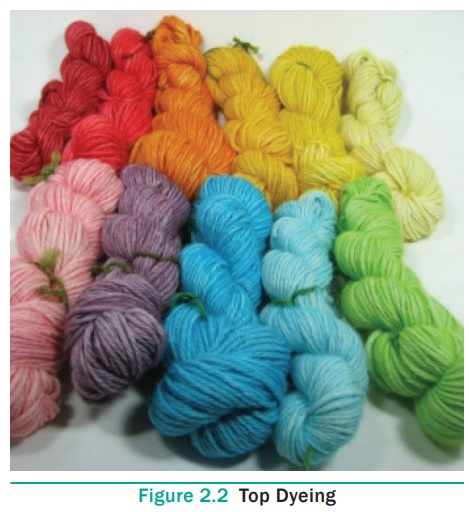

Dope dyeing

Manmade fibres such as polyester and polypropylene are dyed by

this method. In this method, dye is mixed with the spinning solution before the

filament is extruded through the spinneret.

Advantages

·

Dyeing is uniform

·

Dyed textiles have good to excellent colour fastness to washing

and light

Disadvantages

·

The strength of solution dyed filaments are slightly lesser

·

Expensive method

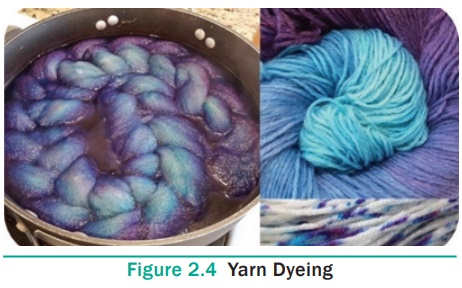

2. Dyeing at Yarn Stage

The process of dyeing at yarn stage is called as yarn dyeing. Yarn

dyeing is preferred to create interesting checks, stripes and plaids in the

fabrics. Yarn dyed fabrics are deeper and richer in colour. Fabric with dyed

warp and undyed weft are example for chambrays. This includes techniques like

skein dyeing, package dyeing, warp-beam dyeing and space dyeing.

Skein Dyeing

In this method, the yarns are loosely wound in hanks or skein

form. The hanks or skeins are hung on perforated rods and immersed in a dye

bath. The dye solution is circulated in and out of the yarn to achieve an even

shade. This method is commonly used for dyeing acrylic and wool yarns.

Advantages

·

Loose arrangement of yarn permits excellent dye penetration

·

Yarns retain softer feel

Disadvantage

·

Most expensive yarn dyeing method

Package Dyeing

Yarns are wound on cones, spools or similar units. These yarn

packages are arranged on perforated rods in a rack and immersed in a tank. The

dye solution is forced outside from the rods and forced back to the centre

under pressure through the packages so that, the dye penetrates the entire

yarn.

Advantages

·

Dyeing capacity is higher (550 kg) when compared to skein dyeing

(200 kg)

·

Material to liquor ratio is less

·

Uniform dyeing

Disadvantages

·

Package dyed yarns do not retain softness and loftiness feel

·

Not suitable for high twist yarns which will not allow dye to

penetrate

Warp-Beam Dyeing

This method is similar to package dyeing. In warp-beam dyeing, the

yarn is wound onto a perforated warp beam and placed in a tank containing dye

solution. Dyeing is carried out under pressure for deeper and uniform

penetration of dye. This method is used for the manufacturing of denims, in

which warp yarns are dyed with indigo and weft yarns are left undyed.

Advantage

Economical than other yarn dyeing methods

Disadvantage

May not produce high fashion fabric since warp yarn will be dyed

in specific colour

Space Dyeing

In this method yarn is not completely dyed, but it is dyed at

intervals. Space dyeing is done by two methods namely, Knit-de-knit method and

OPI space -dye applicator method. In knit-de-knit method, the knitted fabric is

dyed and de-knitted, which results in appearance of alternating dyed and

un-dyed spaces. In OPI space-dye applicator method, the yarns are allowed to

pass through space dye baths at very high speed which results in intermittent

dyeing.

Advantages

·

Produces brighter and deeper shades.

·

Create interesting checks, stripes and plaids.

Disadvantages

·

Costly and time consuming

·

May not create designs to match current fashion

3. Dyeing at Fabric Stage

The process of dyeing woven or knitted fabric is called as piece

dyeing. Piece dyeing methods include beam dyeing, beck or winch dyeing, jig

dyeing, jet dyeing and pad dyeing.

Advantages

·

Uniform dyeing

·

Inexpensive than fibre or yarn dyeing

·

Versatile and flexible in accommodating changing fashion trends.

·

Faster and easier

Disadvantage

·

The ends of the fabric does not have some colour as the remaining

fabric

Beam Dyeing

This process is similar to warp -beam dyeing of yarns. In this

method, the woven or knitted fabrics are wound on perforated beams and immersed

in dye solution. Dye is circulated through the fabric

Beck / Winch Dyeing

This method is done to dye the fabrics of longer length. The

fabric is circulated through the dye bath in tensionless rope form. The ends of

the fabric are tied together to form a loop. The fabric moves over a rail onto

a winch reel which immerses it into the dye bath and draws the fabric up. The

process is repeated till the fabric is dyed uniformly and to the desired colour

shade. About 1000 m or 900 kgs of fabric can be dyed at a time. The dyed

fabrics retain its original softness feel. This method is widely used for

woolen woven and knitted fabrics.

Jig Dyeing

In this method, the fabric is held on rollers at full width and

passed through the dye bath. The fabric is let off from one roller into the dye

bath and wound on to the other roller. After one cycle, the process is reversed

and the fabric is let off from the second roller to the first. The process is

repeated till the desired colour strength is achieved. About 250 kg of fabric

can be dyed at a time. This method is preferred for heat-sensitive

thermoplastic fabrics that cannot be dyed in rope form as they will form

permanent crease or colour streaks in the fabric. This method is not suitable

for knitted or stretch fabrics which should not be subjected to tension and

also to fabrics where a soft feel is required.

Jet Dyeing

In this method the fabric is dyed in a rope form. It is placed in

a heated tube or column where jets of dye solution are thrown on the fabric at

high pressure. The fabric also moves along the tube. The dye solution is

circulated faster than the fabric while colouring it thoroughly. About 500 kg

of fabrics can be jet-dyed at a time. This method of dyeing is suitable for

both woven and knitted fabrics made up of wool, cotton, viscose rayon,

polyester and its blends.

Pad Dyeing

In pad dyeing, the fabric at full width is passed through a trough

containing dye bath. The fabric is then passed between two heavy rollers which

force the dye to penetrate in to the fabric and squeeze out the excess dye

solution. For the dye to set, the fabric is passed through a heat chamber. Then

the dyed fabric is rinsed and dried.

4. Dyeing at Product Stage

This is the last stage of dyeing. When the finished product such

as garment is dyed, it is called as product dyeing or garment dyeing. The

fabric undergoes pre-treatments such as desizing, bleaching and mercerization

before dyeing. The most widely used method for garment dyeing is paddle dyeing.

In this method, garments are packed loosely in net bags. Ten to fifty of such

bags are kept in large tubs containing dye solution. The dye is agitated by a

motor driven paddle which increases the penetration of dye. Garment dyeing is

suitable for products such as sweaters, T-shirts, casual clothing and hosiery.

Advantages

·

Economical

·

No shade variations

Disadvantages

·

Colour bleeding and fading.

·

Not suitable for products with zippers, sewing, threads, lining

etc.

2. Dyeing of Blended Fabrics

When a fabric is made of one type of fibre/ yarn, dyeing process

is simple but when it is composed of more than one kind of yarn as in a blend,

dyeing process is complex. Special procedures are carried out where different

dyes that are suitable for each fibre need to be selected.

1. Union Dyeing

In this method, blended fabrics are dyed to the same shade to get

a solid-coloured fabric. Fabrics can be dyed by one or two bath process. In one

bath process, dyes appropriate for each fibre is added in same dye bath. In two

bath process, dyes are added separately to each fibre subsequent to one

another.

2. Cross Dyeing

In this method, fabrics are dyed in such a way that different

fibres produce different shades with the same colour. Sometimes, one of the

fibre components is left undyed. Cross dyeing results in checks, plaids,

striped and multi-coloured fabrics. Cross dyed fabrics are similar to fibre or

yarn dyed textile materials. If one of the yarns of the fabric is vegetable

fibre and the other is from animal fibre, then the fabric is dyed in two

separate baths, suitable for each fibre. This produces colourful effects.

Related Topics