Textiles and Dress Designing - Classification of Dyes | 12th Textiles and Dress Designing : Chapter 2 : Dyeing

Chapter: 12th Textiles and Dress Designing : Chapter 2 : Dyeing

Classification of Dyes

Classification of Dyes

Dyes are organic compounds with two components namely Chromophore,

which imparts colour and Auxochrome that help in substantivity of dyes. They

are classified into natural dyes and synthetic dyes.

1. Natural Dyes

Natural dyes are colour substances obtained from natural sources.

Natural dyes are used for all types of textile dyeing and printing until the

middle of nineteenth century. The use of natural dyes were reduced due to the

advent of synthetic dyes, though they were economical and posses excellent

fastness properties. However, the growing consumer awareness on the harmful

impact of synthetic dyes,

concern for environment worldwide and stringent environmental laws lead to the

revival of natural dyes.

1. Advantages of Natural Dyes

·

Natural dyes are extracted from natural sources and hence they are

eco-friendly

·

Produces soft and soothing colours

·

These dyes provide excellent protection from UV rays

·

Natural dyes like turmeric have anti-microbial properties and

hence protect the fabrics and wearers from microbial attack

·

Some natural dyes possess mosquito repellent and flame resistant

property

·

They can be obtained from the natural sources which are abundant

in a particular area. Hence supply of raw materials will be continuous and

transport charges will be lower

2. Disadvantages of Natural Dyes

·

Natural dyes are difficult to store

·

Dye extraction is a time consuming process

·

Reproducibility of the same colour shade is difficult

·

Impurities in natural dyes fades away the colour produced

·

Availability of these dyes depends on the seasons

·

Natural dyeing process is difficult to standardize

Classification of Natural Dyes

Natural dyes are classified in to three types based on the source

of origin namely vegetable dyes, animal dyes and mineral dyes.

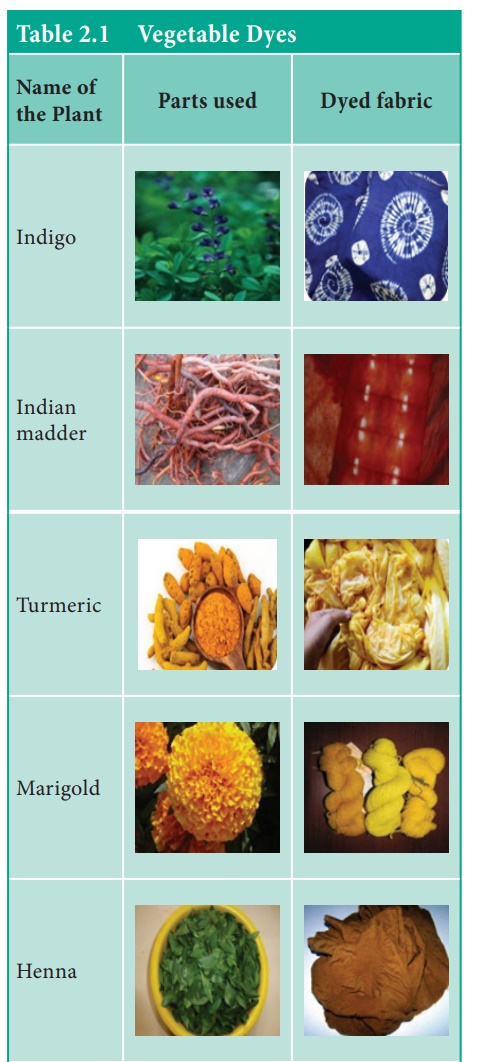

2. Vegetable Dyes

The earliest dyes were of vegetable origin, discovered by

accidentally staining garments with juices of fruits or plants. Vegetable dyes

are obtained from different parts of plants such as leaves, flowers, fruits,

pods, bark etc. These vegetable dyes can be applied directly or with different

mordants.

Indigo: Indigo (blue dye) is called as the king of all natural

dyestuffs. It imparts blue colour. It is extracted from the leaves of the

leguminous plant, Indigofera tinctoria. It is suitable for dyeing cotton

and wool.

Indian Madder: It produces shades of red on textile

fabrics. It is used for dyeing cotton and woollen fabrics. It is extracted from

roots of Rubia tinctoria.

Turmeric: It produces shades of yellow on fabrics. It is suitable for

dyeing cotton, silk and wool. The yellow dye is extracted from the ground root

(rhizome) of turmeric plant (Curcuma longa).

Marigold: It is extracted from lemon or orange coloured marigold (Calendula

officinalis) flower. It is suitable for dyeing both silk and wool

fibres.

Henna: The dye is extracted from the dried leaves of Henna plant, Lawsonia

inermis. It produces yellowish orange colour. It is suitable for

dyeing wool and silk fibres.

Tea: Leaves of tea plants (Camellia sinensis) or

tea powder is used to extract dye. It produces different shades of

brown.

Onion: The dye is extracted from the outer most skin or peel of

the onion (Allium cepa). The onion skins if properly dried can be used

for one year.

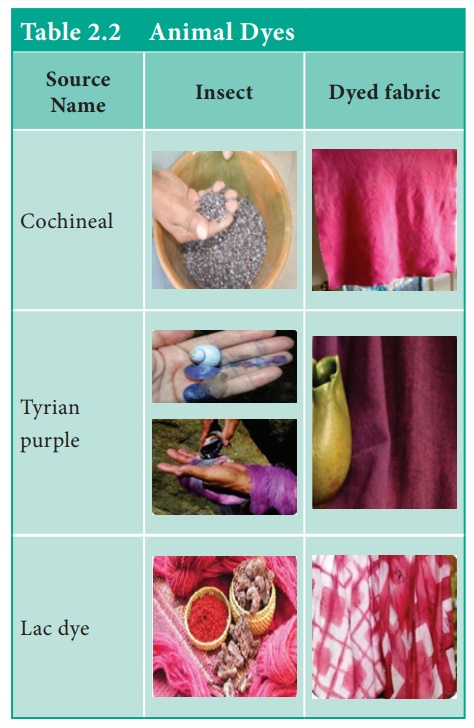

3. Animal Dyes

Dyes extracted from certain insects and invertebrates are called

as animal dyes. Various shades of red and purple were obtained from animal

origin. Cochineal, Tyrian purple and Lac are the commonly used animal dyes.

1. Cochineal

Cochineal dye is extracted from the dried bodies of the female red

bug (Dactylopius coccus). It produces crimson and scarlet colours with

mordants aluminium and tin oxide. This dyestuff was mostly used for dyeing wool

and silk. These dyes exhibit excellent fastness properties.

2. Tyrian Purple

This dye is extracted from the sea snails found in Mediterranean

Sea. The amount of dye produced was very limited and therefore very expensive.

Hence, it is called Royal purple.

3. Lac Dye

This dye is extracted from the fluid secreted by the lac insect (Lauifer

lacca), which lives on the twigs of the banyan trees and other

varieties.

It produces crimson and scarlet colours. These dyes possess good

fastness to light and washing.

Animal dyes are also obtained from murex snail (purple colour) and

Octopus/ Cuttle fish (Sepia brown).

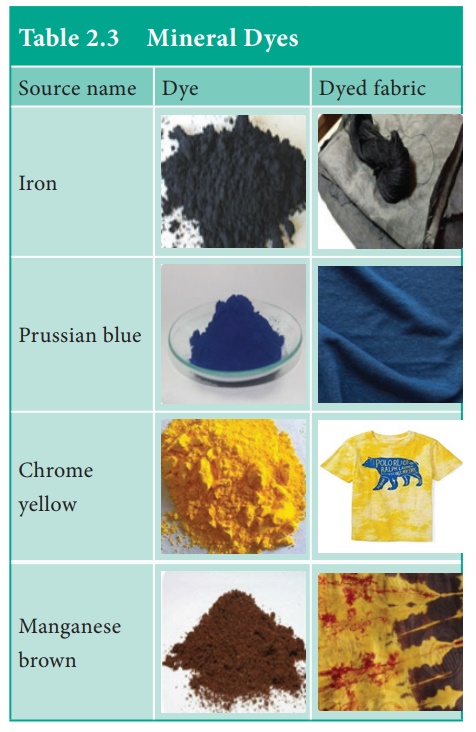

4. Mineral Dyes

Dyes extracted from mineral sources are called as mineral dyes.

Most widely used mineral dyes are Iron, which produces yellowish brown shades,

chrome yellow, prussian blue and manganese brown. The dyes obtained from

mineral sources may be poisonous and hence are not being used commercially.

5. Synthetic Dyes

Dyes that are produced chemically are called as synthetic dyes.

These are classified based on the chemical composition of the dye.

1. Direct Dyes

When a dye colours the fabric directly without the help of any

fixing agent, the dye is said to be a direct dye. Direct dyes are water

soluble. They are easy to produce, simple to apply and cheap in cost of

production and application. Direct dyes are anionic in nature and have greater

affinity for cellulosic fibres. They are used to dye cellulose fibres without a

mordant in bright shades and they produce a wide range of colours. A levelling

agent such as sodium carbonate is added for even dyeing. At the end of dyeing,

exhaustion agent such as salt (NaCl) is added which helps the dye to leave the

liquor and get attached to the fibre. Some direct dyes are used to dye wool,

silk and nylon. Direct dyes can be applied to wide variety of textile materials

such as apparel, upholstery fabrics, draperies, linings and automotive fabrics.

Most direct dyes have good fastness to light but poor wash fastness.

2. Reactive Dyes

Dyes that react with the fibres and form covalent bonds are called

as reactive dyes. They become an integral part of the fibre. They are water

soluble and are used to dye cellulose, protein and polyamide fibres. They

produce full range of bright shade across the spectrum. They exhibit excellent

wash fastness and good light fastness properties. Dyeing of fibre with reactive

dyes involves 3 steps, namely exhaustion of dye (NaCl or Glauber’s salt),

fixation of dye (sodium carbonate or sodium hydroxide) and washing off.

3. Basic Dyes

Basic dyes have cationic or basic groups (positively charged) and

hence they are also known as cationic dyes. Basic dyes react with the acidic

groups present in the fibres and form electrovalent bonds. Basic dyes are

soluble in alcohol but not easily soluble in water. Basic dyes exhibit

brilliant shades of colour which is not shown by other dye classes. Basic dyes

are suitable for dyeing wool, silk and acrylic, but they have no affinity

towards cellulosic fabrics. Basic dyes are used along with a mordant for fibres

such as cotton, linen, acetate, nylon and polyester. Basic dyes show moderate

light and wash fastness. For dye preparation, the dyestuff is mixed with equal

amount of acetic acid followed by warm water under constant stirring.

4. Acid Dyes

Water soluble dyes that require acid (sulphuric, acetic, formic

acid etc.,) in dye bath to dye silk or wool are called as acid dyes. These acid

dyes are mostly sodium salts of organic acids. When dissolved in water, acid

dyes produce negative ions (anions or acidic groups) which react with positive

ions of protein fibres and get attached to the fibre through electrovalent

bonds. Acid dyes are similar to direct dyes however they cannot be applied to

cellulosic fibre due to slight variations in structure. Acid dyes have greater

affinity for protein and polyamide fibres. They posses very good fastness to

washing and good fastness to light. A large colour range is available with acid

dyes. They are inexpensive.

5. Mordant or Chrome Dyes

Natural dyes and some synthetic dyes do not have affinity towards

fibres. With the help of some chemicals, they can be used to dye fibres. These

chemicals are called mordants or mordant dyes. Mordant dyes have affinity for

both fibre and dye and form a linkage between the dye molecule and the fibre.

6. Disperse Dyes

Disperse dyes are insoluble in water. Their solubility is

increased by increasing temperature and by adding dispersing agents. They are

suitable for dyeing hydrophobic fibres like nylon, polyester, acrylic and other

synthetic fibres. Disperse dyes are non -ionic or neutral in nature. They have

an excellent fastness to washing and sunlight exposure.

7. Vat Dyes

These dyes were initially fermented in a large wooden vessel known

as vats and hence the name “vat dyes”. They are insoluble in water but

soluble in alkali. Vat dyes are accepted into the fibre in a reduced or vatted

form. When it is re-oxidized, it is then fixed to the fibre firmly. The dyes

are treated with a reducing agent that converts them into leuco compounds,

which is soluble in alkalis. The process of making the dyes soluble is known as

Vatting. The leuco compounds are either colourless or exhibit a colour that is

different from the colour of final product, which is achieved after oxidation.

Once the dye is attached to the fibre, it gets oxidised and changed into an

insoluble colour product that gets trapped inside the fibre. Indigo, an example

of vat dyes has been used in India for long periods.

In the soluble form, vat dyes have excellent affinity for

cellulosic fibres. Vat dyes are the fastest dyes for cotton, linen and rayon.

They may be also applied to wool, nylon, polyester and acrylics with the use of

a mordant. Vat dyes are resistant to light, acids and alkalies.

The basic principles of vat dye application can be summarized as

follows:

·

Conversion of the insoluble vat dye into the soluble leuco form by

reduction or “vatting”.

·

Absorption of the soluble reduced dye by the fibres

·

Conversion of the absorbed dye back to the insoluble state by

oxidation

·

After treatment of the dye or printed material in a hot detergent

bath to produce the true and stable shade with maximum fastness

8. Sulphur Dyes

Presence of sulphur is the characteristic feature of sulphur dyes.

Like vat dyes, sulphur dyes are water insoluble and made soluble by the

addition of reducing agents and alkali as solubiliser. They are converted into

soluble leuco compounds by using sodium sulphide or sodium hydrosulphite as

reducing agent. The leuco compounds have high affinity for cellulosic fibres.

After dyeing the fabric, the dye is converted into insoluble form by the

addition of potassium dichromate and acetic acid. Sulphur dyes do not produce

brighter shades. They are cheap and produce colours like navy blue, black,

khaki and olive green. They are used for black more than any other colours.

They have excellent wash fastness property. The fabric loses its softness after

dyeing with sulphur dyes.

9. Azoic Dyes or

Napthol Dyes

Unlike other colouring matters, the azoic dyes are not prepared as

dye stuffs but have to be produced directly in the fibre by the combination of

their constituents. The first component, napthol in presence of sodium

hydroxide give colourless or faintly yellow or brown colour when applied on

cotton at room temperature. The naptholated fabric when immersed in the second

bath containing the second component base along with the acid and sodium

nitrite at ice cold temperature produces bright colour which is insoluble in

water. The two components form azo group during coupling. So the dye is known

as azoic dye. Since it is formed inside the fibre, it is called ingrain

dye. Azo dyes are also called as ice colours since their application

involves use of ice to lower the temperature. They are widely used on

cellulosic fibres and have limited application on acrylic, nylon and polyester.

Azo dyes exhibit bright colours. They have good colour fastness to washing and

light.

10. Pigment Dyes

Pigments are not true dyes because they have no affinity for the

fibre. They are applied and held to the fabric with the help of adhesives and

resins. Pigments are commonly used in dope dyeing and printing. Use of pigments

saves both time and cost. Vat dye is called as dye when applied on fabric in

solubilized form and is termed as pigment when applied on fabric in insoluble

form using a binder. Pigment dyes exhibit excellent light fastness.

11. Optical Brightners

These dyes are also called as colourless dyes or fluorescent

whiteners. These dyes absorb light at UV-region and emit blue light in visible

region. It may be applied during bleaching or with the final finish. These dyes

have affinity for cotton but are also used for wool, nylon, acetate and

acrylics.

Related Topics