Chapter: Mechanical : Design of Machine Elements : Design of Shafts and Couplings

Design of Shafts and Couplings

DESIGN OF

SHAFTS AND COUPLINGS

Material

Used for Shafts

The

material used for shafts should have the following properties :

It should

have high strength.

It should

have good machinability.

It should

have low notch sensitivity factor.

It should

have good heat treatment properties.

It should

have high wear resistant properties.

Types of Shafts

The

following two types of shafts are important from the subject point of view :

1. Transmission shafts. These

shafts transmit power between the source and the machines absorbing power. The

counter shafts, line shafts, over head shafts and all factory shafts are

transmission shafts. Since these shafts carry machine parts such as pulleys,

gears etc., therefore they are subjected to bending in addition to twisting.

Machine shafts. These

shafts form an integral part of the machine itself. The crank shaft is an

example of machine shaft.

Stresses in Shafts

The

following stresses are induced in the shafts :

Shear stresses due to the transmission of torque

(i.e. due to torsional load).

Bending stresses (tensile or compressive) due to

the forces acting upon machine elements like gears, pulleys etc. as well as due

to the weight of the shaft itself.

Stresses due to combined torsional and bending

loads

Design of Shafts

The

shafts may be designed on the basis of

Strength,

and

Rigidity

and stiffness.

In

designing shafts on the basis of strength, the following cases may be

considered :

Shafts subjected to twisting moment or torque only,

Shafts subjected to bending moment only,

Shafts

subjected to combined twisting and bending moments, and

Shafts subjected to axial loads in addition to

combined torsional and bending loads

Shafts

Subjected to Bending Moment Only

When the shaft is subjected to a bending moment

only, then the maximum stress (tensile or compressive) is given by the bending

equation. We know that

M/I

= σb/y

where M = Bending moment,

I =

Moment of inertia of cross-sectional area of the shaft about the axis of

rotation,

σb =

Bending stress, and

y =

Distance from neutral axis to the outer-most fibre.

Shafts

Subjected to Twisting Moment Only

When the shaft is subjected to a twisting moment

(or torque) only, then the diameter of the shaft may be obtained by using the

torsion equation. We know that

T

/J = τ/r

where T = Twisting moment (or torque) acting upon

the shaft,

J = Polar

moment of inertia of the shaft about the axis of rotation, τ = Torsional shear

stress, and

r =

Distance from neutral axis to the outer most fibre

d / 2;

where d is the diameter of the shaft.

Shafts Subjected to Combined Twisting Moment and

Bending Moment

When the

shaft is subjected to combined twisting moment and bending moment, then the

shaft

must be

designed on the basis of the two moments simultaneously. Various theories have

been suggested to account for the elastic failure of the materials when they

are subjected to various types of combined stresses. The following two theories

are important from the subject point of view:

Maximum shear stress theory or Guest's theory. It

is used for ductile materials such as mild steel.

Maximum normal stress theory or Rankine’s theory.

It is used for brittle materials such as cast iron.

Let τ =

Shear stress induced due to twisting moment, and

σb =

Bending stress (tensile or compre ssive) induced due to bending moment.

Shafts

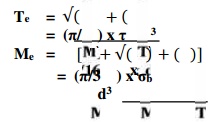

Subjected to Fluctuating Loads

In the

previous articles we have assumed that the shaft is subjected to constant

torque and bending moment. But in actual practice, the shafts are subjected to

fluctuating torque and bending moments. In order to design such shafts like

line shafts and counter shafts, the combined shock and fatigue factors must be

taken into account for the computed twisting moment (T ) and bending moment (M

). Thus for a shaft subjected to c ombined ben ding and torsion, the equivalent

twisting moment,

KEYS:

A key is a piece of mild steel inserted between the

shaft and hub or boss of the pulley to connect these together in order to

prevent relative motion between them. It is always inserted parallel to the

axis of the shaft. Keys are used as temporary fastenings and are subjected to

considerable crushing and shearing stresses. A keyway is a slot or recess in a

shaft and hub of the pulley to accommodate a key.

Types

of Keys

The

following types of keys are important from the subject point of view:

Sunk keys,

Saddle keys,

Tangent keys,

Round keys,

Splines.

Shaft Coupling

Shafts are usually available up to 7 metres length

due to inconvenience in transport. In order to have a greater length, it

becomes necessary to join two or more pieces of the shaft by means of a

coupling.

Shaft

couplings are used in machinery for several purposes, the most common of which

are the following :

To provide for the connection of shafts of units

that are manufactured separately such as a motor and generator and to provide

for disconnection for repairs or alternations.

To provide for misalignment of the shafts or to

introduce mechanical flexibility.

To reduce the transmission of shock loads from one

shaft to another.

To introduce protection against overloads.

It should have no projecting parts.

Shaft

couplings are divided into two main groups as follows:

1. Rigid

coupling.

It is used to connect two shafts which are

perfectly aligned. Following types of rigid coupling are important from the

subject point of view:

Sleeve or muff coupling.

Clamp or split-muff or compression coupling, and

Flange coupling.

2. Flexible

coupling.

It is used to connect two shafts having both

lateral and angular misalignment. Following types of flexible coupling are

important from the subject point of view :

Bushed pin type coupling,

Universal coupling, and

Oldham coupling.

Related Topics