Chapter: Mechanical : Design of Transmission Systems : Design of Cam Clutches and Brakes

Design of Cam Clutches and Brakes

DESIGN OF CAM CLUTCHES AND BRAKES

Introduction

A clutch

is a machine member used to connect a driving shaft to a driven shaft so that

the driven shaft may be started or stopped at will, without stopping the

driving shaft. The use of a clutch is mostly found in automobiles. A little

consideration will show that in order to change gears or to stop the vehicle,

it is required that the driven shaft should stop, but the engine should

continue to run. It is, therefore, necessary that the driven shaft should be

disengaged from the driving shaft. The engagement and disengagement of the

shafts is obtained by means of a clutch which is operated by a lever.

Types of Clutches

Following

are the two main types of clutches commonly used in engineering practice :

1. Positive

clutches, and

2. Friction

clutches

Positive Clutches

The

positive clutches are used when a positive drive is required. The simplest type

of a positive clutch is a jaw or claw clutch. The jaw clutch permits one shaft

to drive another through a direct contact of interlocking jaws. It consists of

two halves, one of which is permanently fastened to the driving shaft by a sunk

key. The other half of the clutch is movable and it is free to slide axially on

the driven shaft, but it is prevented from turning relatively to its shaft by

means of feather key. A square jaw type is used where engagement and

disengagement in motion and under load is not necessary. This type of clutch

will transmit power in either direction of rotation. The spiral jaws may be

left-hand or right-hand, because power transmitted by them is in one direction

only. This type of clutch is occasionally used where the clutch must be engaged

and disengaged while in motion. The use of jaw clutches are frequently applied

to sprocket wheels, gears and pulleys. In such a case, the non-sliding part is

made integral with the hub.

Friction Clutches

A

friction clutch has its principal application in the transmission of power of

shafts and machines which must be started and stopped frequently. Its

application is also found in cases in which power is to be delivered to

machines partially or fully loaded. The force of friction is used to start the

driven shaft from rest and gradually brings it up to the proper speed without

excessive slipping of the friction surfaces. In automobiles, friction clutch is

used to connect the engine to the drive shaft. In operating such a clutch, care

should be taken so that the friction surfaces engage easily and gradually bring

the driven shaft up to proper speed. The proper alignment of the bearing must

be maintained and it should be located as close to the clutch as possible. It

may be noted that :

1. The

contact surfaces should develop a frictional force that may pick up and hold

the load with reasonably low pressure between the contact surfaces.

2. The heat

of friction should be rapidly

3. The

surfaces should be backed by a material stiff enough to ensure a reasonably

uniform distribution of pressure.

Material for Friction Surfaces

The

material used for lining of friction surfaces of a clutch should have the

following characteristics:

1. It should

have a high and uniform coefficient of friction.

2. It should

not be affected by moisture and oil.

3. It should

have the ability to withstand high temperatures caused by slippage.

4. It should

have high heat conductivity.

5. It should

have high resistance to wear and scoring.

DESIGN OF A DISC OR PLATE CLUTCH

Consider

two friction surfaces maintained in contact by an axial thrust (W) .Forces on a

disc clutch.

Let T =

Torque transmitted by the clutch,

p =

Intensity of axial pressure with which the contact surfaces are held

together,

r1 and r2

= External and internal radii of friction faces,

r = Mean

radius of the friction face, and

μ =

Coefficient of friction.

Consider

an elementary ring of radius r and thickness dr

We know

that area of the contact surface or friction surface = 2π r.dr

∴ Normal or axial force on the ring,

δW = Pressure × Area = p × 2 π r.dr

and the

frictional force on the ring acting tangentially at radius r,

∴ Frictional torque Fr = μ × δW = μ.p × 2 π r.dr

acting on the ring,

Tr = Fr × r = μ.p × 2 π r.dr × r = 2 π

μ p. r2.dr

We shall

now consider the following two cases :

1. When

there is a uniform pressure, and

2. When

there is a uniform axial wear.

1. Considering uniform pressure. When

the pressure is uniformly distributed over the entire

area of

the friction face then the intensity of pressure,

p = W / π

– [(r1)2 - (r2)2]

where W =

Axial thrust with which the friction surfaces are held together.

We have

discussed above that the frictional torque on the elementary ring of radius r

and thickness dr is

Tr = 2π

μ.p.r2.dr

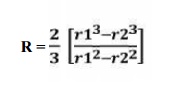

∴Integrating this equation within the

limits from r2 to r1 for the total friction torque. Total frictional torque

acting on the friction surface or on the clutch,

2. Considering uniform axial wear. The

basic principle in designing machine parts that are subjected to wear due to

sliding friction is that the normal wear is proportional to the work of

friction. The work of friction is proportional to the product of normal

pressure ( p) and the sliding velocity (V). Therefore,∝ ∝

Normal wear Work

of friction p.V

or p.V =

K (a constant) or p = K/V ...(i)

It may be

noted that when the friction surface is new, there is a uniform pressure

distribution over the entire contact surface. This pressure will wear most

rapidly where the sliding velocity is maximum and this will reduce the pressure

between the friction surfaces.

This

wearing-in process continues until the product p.V is constant over the entire

surface. After this, the wear will be uniform.

Let p be

the normal intensity of pressure at a distance r from the axis of the clutch.

Since the intensity of pressure varies inversely with the distance, therefore

p.r = C

(a constant) or p = C/r ...(ii)

and the

normal force on the ring,

δW =

p.2πr.dr

= (C/r)

2π r dr

2πC.dr

∴ Total force acing=on the friction surface,

R = (r1 + r2)/2

= Mean radius of the friction surface.

BRAKE

Introduction

A brake

is a device by means of which artificial frictional resistance is applied to a

moving machine member, in order to retard or stop the motion of a machine. In

the process of performing this function, the brake absorbs either kinetic

energy of the moving member or potential energy given up by objects being

lowered by hoists, elevators etc.

The

energy absorbed by brakes is dissipated in the form of heat. This heat is

dissipated in the surrounding air (or water which is circulated through the

passages in the brake drum) so that excessive heating of the brake lining does

not take place. The design or capacity of a brake depends upon the following

factors :

1. The unit

pressure between the braking surfaces,

2. The

coefficient of friction between the braking surfaces,

3. The

peripheral velocity of the brake drum

4. The

projected area of the friction surfaces, and

5. The ability

of the brake to dissipate heat equivalent to the energy being absorbed.

The major

functional difference between a clutch and a brake is that a clutch is used to

keep the driving and driven member moving together, whereas brakes are used to

stop a moving member or to control its speed.

Energy Absorbed by a Brake

The

energy absorbed by a brake depends upon the type of motion of the moving body.

The motion of a body may be either pure translation or pure rotation or a

combination of both translation and rotation. The energy corresponding to these

motions is kinetic energy. Let us consider these motions as follows :

1. When the

motion of the body is pure translation. Consider a body of mass (m) moving with

a velocity v1 m / s. Let its velocity is reduced to v2 m / s by applying the

brake. Therefore, the change in kinetic energy of the translating body or

kinetic energy of translation,

E1 =

(1/2) m [(v1)2 - (v2)2]

This

energy must be absorbed by the brake. If the moving body is stopped after

applying the brakes, then v2 = 0, and

E1 = (1/2)

m (v1)2

2. When

the motion of the body is pure rotation. Consider a body of mass moment of

inertia I (about a given axis) is rotating about that axis with an angular

velocity ω1 rad / s. Let its angular velocity is reduced to ω2 rad / s after

applying the brake. Therefore, the change in

kinetic

energy of the rotating body or kinetic energy of rotation,

E2 =

(1/2) I [(ω1)2 - (ω2)2]

This

energy must be absorbed by the brake. If the rotating body is stopped after

applying the brakes, then ω2 = 0, and

E1 = (1/2)

I (ω1)2

3. When

the motion of the body is a combination of translation and rotation. Consider a

body having both linear and angular motions, e.g. in the locomotive driving

wheels and wheels of a moving car. In such cases, the total kinetic energy of

the body is equal to the sum ∴of the kinetic energies of translation and

rotation.

Total

kinetic energy to be absorbed by the brake,

E = E1 +

E2

Sometimes,

the brake has to absorb the potential energy given up by objects being lowered

by hoists, elevators etc. Consider a body of mass m is being lowered from a

height h1 to h2 by applying the brake. Therefore the change in potential

energy,

E3 = m.g

(h1 – h2)

Heat to be Dissipated during Braking

The

energy absorbed by the brake and transformed into heat must be dissipated to

the surrounding air in order to avoid excessive temperature rise of the brake

lining. The upon the mass of the brake drum, the braking time and the heat

dissipation capacity of the brake. The highest permissible temperatures

recommended for different brake lining materials are given as follows :

1. For

leather, fibre and wood facing = 65 – 70°C

2. For

asbestos and metal surfaces that are slightly lubricated = 90 – 105°C

3. For

automobile brakes with asbestos block lining = 180 – 225°C

Since the

energy absorbed (or heat generated) and the rate of wear of the brake lining at

a particular speed are dependent on the normal pressure between the braking

surfaces, therefore it is an important factor in the design of brakes. The

permissible normal pressure between the braking surfaces depends upon the

material of the brake lining, the coefficient of friction and the maximum rate

at which the energy is to be absorbed. The energy absorbed or the heat

generated is given by

E = Hg =

μ.RN.v

= μ.p.A.v

(in J/s or watts) ...(i)

where μ = Coefficient of friction,

RN =

Normal force acting at the contact surfaces, in newtons,

p =

Normal pressure between the braking surfaces in N/m2,

A =

Projected area of the contact surfaces in m2, and

v =

Peripheral velocity of the brake drum in m/s.

The heat

generated may also be obtained by considering the amount of kinetic or

potential energies which is being absorbed. In other words,

Hg = EK +

EP

where EK = Total kinetic energy absorbed, and

EP =

Total potential energy absorbed.

The heat

dissipated (Hd) may be estimated by

Hd = C

(t1 – t2) Ar ...(ii)

where C =

Heat dissipation factor or coefficient of heat transfer in W /m2 / °C

t1 – t2 =

Temperature difference between the exposed radiating surface and the

surrounding air in °C, and

Ar = Area

of radiating surface in m2.

The value

of C may be of the order of 29.5 W / m2 /°C for a temperature difference of

40°C and increase up to 44 W/m2/°C for a temperature difference of 200°C.

The

expressions for the heat dissipated are quite approximate and should serve only

as an indication of the capacity of the brake to dissipate heat. The exact

performance of the brake should be determined by test.

It has

been found that 10 to 25 per cent of the heat generated is immediately

dissipated to the surrounding air while the remaining heat is absorbed by the

brake drum causing its temperature to rise. The rise in temperature of the

brake drum is given by

t = Hg /

(m.c) ...(iii)

where t = Temperature rise of the brake drum in °C

Hg = Heat

generated by the brake in joules,

m = Mass

of the brake drum in kg, and

c =

Specific heat for the material of the brake drum in J/kg °C.

In

brakes, it is very difficult to precisely calculate the temperature rise. In

preliminary design analysis, the product p.v is considered in place of

temperature rise. The experience has also shown that if the product p.v is

high, the rate of wear of brake lining will be high and the brake life will be

low. Thus the value of p.v should be lower than the upper limit value for the

brake lining to have reasonable wear life. The following table shows the

recommended values of p.v as suggested by various designers for different types

of service.

SOLVED PROBLEMs

1.

A single

plate clutch with both sides effective; is required to transmit 25 kw at 900

rpm. t hw outer diameter of the plate is 350 mm. the maximum intensity of

pressure over the friction surface is not to exceed 0.1 N/mm2 .

considering uniform wear criteria and assuming coefficient of friction as 0.25;

determine (i) the inner diameter of the plate (ii) axial force required to

engage the clutch.

Given;

P= 25 kw

; N =900 rpm ;2r =350 mm ; P max = 0.1 N/mm2 ; µ = 0.25

Sol:-

I.Inner diameter of the plate

Subtracting

the relation (ii) in (i) and using the values,

r2

[(0.175)2 – r2] = 0.001689

0.031r2 - r2 3 = 0.001689 By trial and

error method,

r2 =

0.136m

II.Axial force required to engage the clutch (F)

= 2 π* 0.1

*106 * 0.136* (0.175 – 0.136 ) * 2

= 6665.2 N

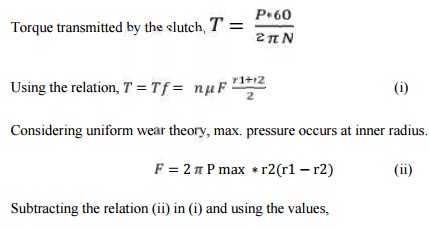

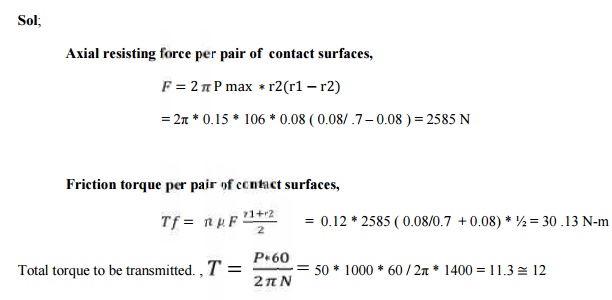

2. A multiple – disc clutch transmits 50

kw of power at 1400 rom. Axial intensity of pressure not to exceed 0.12 1 N/mm2, and the coefficient of friction

of the friction surfaces is 0.12. the inner radius of the discs is 80 mm, and

is .7 times the outer radius. Determine number of disc required to transmit the

given power. Assume uniform wear condition.

Given;

P = 60

kw; N = 1400rpm; P max = 0.15 N/mm2; µ = 0.12; r2 = 80mm;

r1 = r2/ 0.7

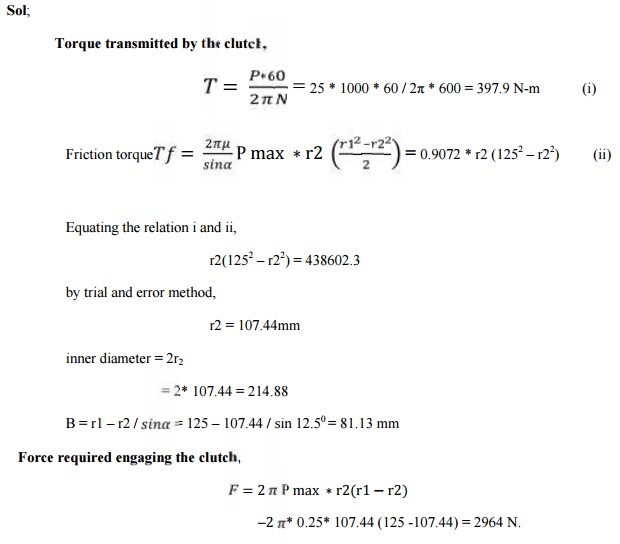

3. A cone clutch with asbestos friction lining,

transmits 25 kw at 600 rpm. The coefficient is 0.25 and the maximum intensity

of pressure is 0.25 N/ mm2. The semi cone angle is 12.50.

the outer diameter of friction lining is 250 mm . Considering uniform wear

theory. Determine

i. the inner diameter of the friction lining,

ii. the face width of friction lining and

iii.the force

required to engage to the clutch.

Given;

P = 25kw;

N = 600rpm; P max = 0.25 N/mm2; µ = 0.25; α = 12.50;

2r1 = 250mm

Sol;

4. A single block brake is shown in figure.

The diameter of the drum is 300 mm and the angle of contact is 900. If the operating force of 600N is

applied at the end of a lever and the coefficient of friction between the drum

and lining is 0.3 determine the torque that may be transmitted by the block

brake.

Page no.

27.16(machine desing)

Given;

L =

550mm; x= 250mm; a = 50mm; r = 2θ; 900 = π / 2 rad ; F = 600 N; µ =

0.3

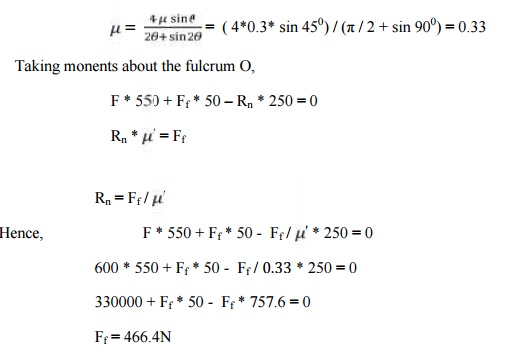

Sol;

In the

present case the angle of contact is greater than 600. Hence, the

equivalent coefiicient of friction is given by,

Torque

transmitted by the brake , Tf = Ff * r

= (466.4

* 150 ) / 1000 = 70N-m

Related Topics